30 | WPM 3 www.stiebel-eltron.com

INSTALLATION

Installation

10.4 Electrical connection

10.4.1 General

DANGER Electrocution

Carry out all electrical connection and installation work

in accordance with national and regional regulations.

DANGER Electrocution

Only use a permanent connection to the power supply.

Ensure the appliance can be separated from the power

supply by an isolator that disconnects all poles with at

least 3 mm contact separation. This requirement can be

met with contactors, circuit breakers, fuses/MCBs, etc.

Note

The specified voltage must match the mains voltage. Ob-

serve the type plate.

When connecting the power, observe the relevant electrical

connection diagram.

The supply voltage at terminal L and the phase L' – switched by

the power supply utility – must be routed via the same residual

current device, as they share a neutral conductor in the WPM3.

Ensure that L and L' are in phase.

Disconnect all heating system poles from the mains power

supply before installation.

No fuses/MCBs for connected consumers are provided in the

WPM3 or in the wall mounting enclosure. A fuse/MCB for con-

nected consumers may be connected in series via terminal L* or

pumps L (see also heat pump connection diagram).

Circulation pumps and mixers

When making these connections, observe the maximum relay

capacity (2 A/250 V AC) and the maximum controller capacity

(10 A/250 V AC).

The DHW circulation pump relay output can be used for various

purposes, subject to the parameter settings.

!

Material losses

Only connect energy efficient circulation pumps ap-

proved by us.

If energy efficient circulation pumps are used that have

not been approved by us, use an external relay with a

breaking capacity of at least 10A/250VAC or our WPM-

RBS relay set.

The following energy efficient circulation pumps have been ap-

proved by us for direct connection to the heat pump manager:

Part no.:

UP 25/7.0 E 232942

UP 25/7.5 E 232943

UP 25/7.5 PCV 235949

UP 30/7.5 E 233947

WPKI-HK E 233602

WPKI-HKM E 233603

10.4.2 Electrical connection WPMW 3

The cable entries in the wall mounting enclosure are suitable for

rigid and flexible cables with an outside diameter of between

6mm and 12mm.

!

Material losses

The BUS cables, power cables and sensor leads must be

installed separately.

Mains and low voltage power are routed separately in the wall

mounting enclosure.

Route the low voltage leads into the left and right of the wall

mounting enclosure from below.

Route the power cables into the inlet ducts above the junc-

tion box.

When connecting the power supply, ensure the earth con-

ductor is correctly connected. Secure all cables to the wall

immediately below the wall mounting enclosure using cor-

rect strain relief fittings. The red wedges supplied are de-

signed to secure the cables inside the enclosure.

Check the function of the strain relief fittings.

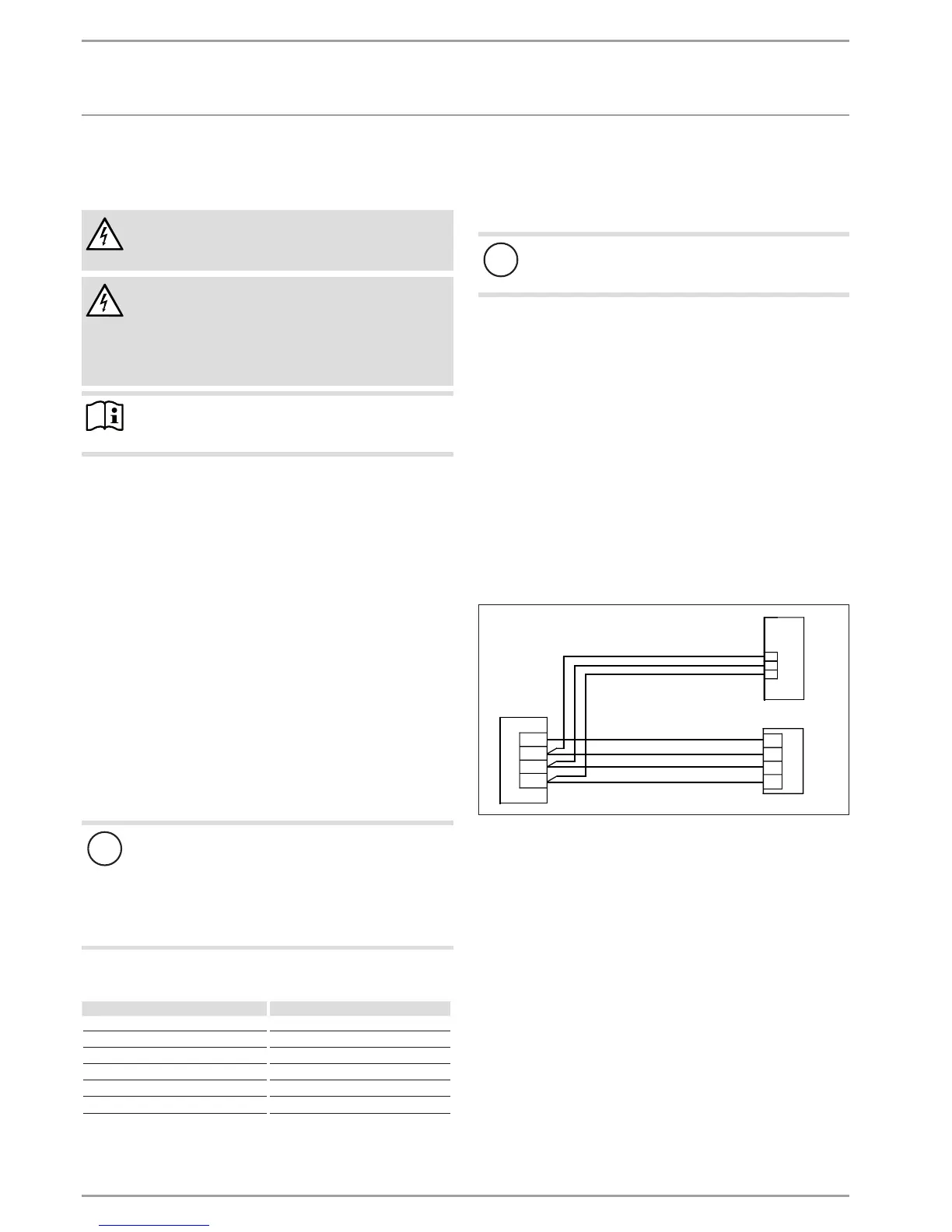

Connecting BUS cables

Install a J-Y (St) 2 x 2 x 0.8mm² cable as the BUS cable to the

heat pump.

A3

A2

11 1213 14

H L - +

A1

X2

4321

26�04�01�0066

A1 WPMW 3

A2 Programming unit

A3 Heat pump

Loading...

Loading...