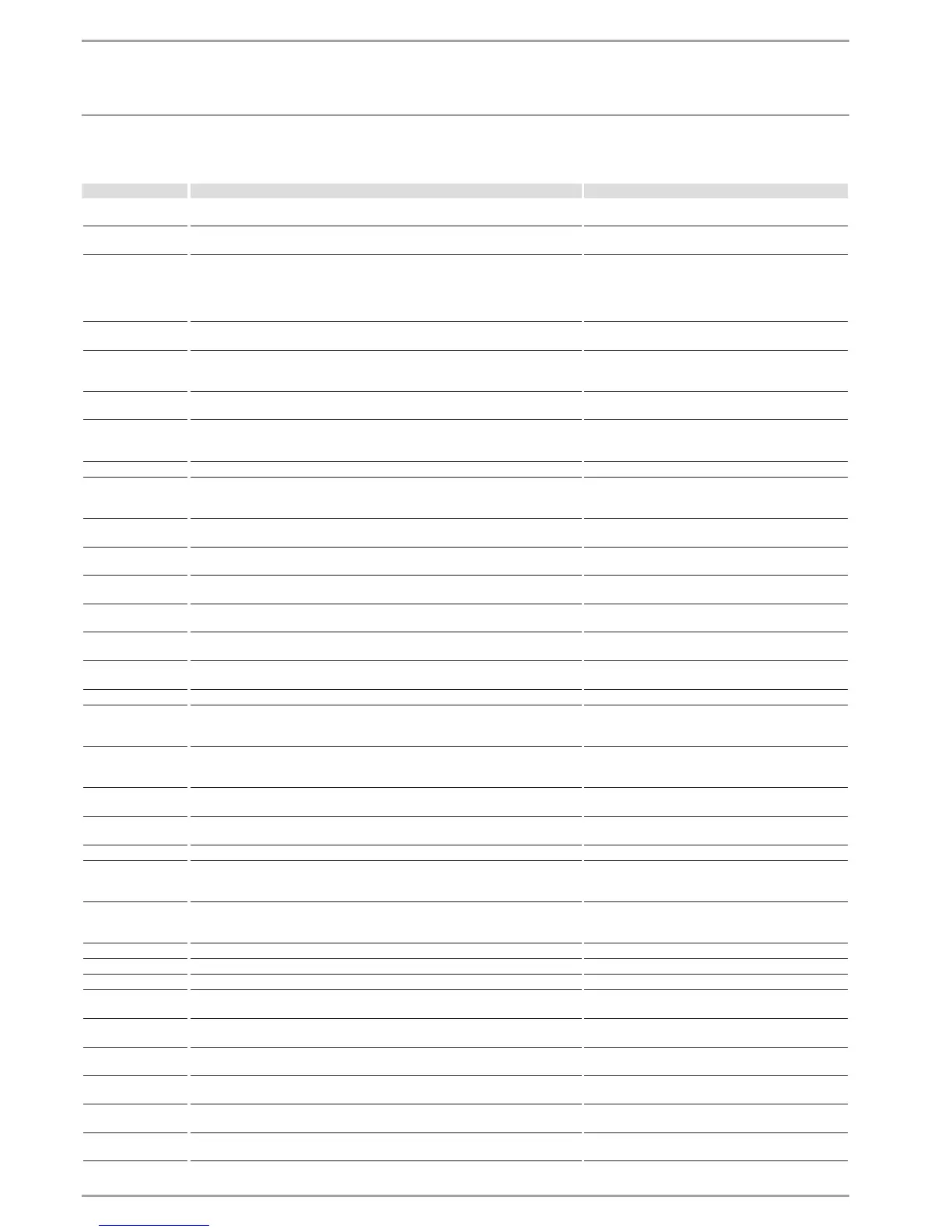

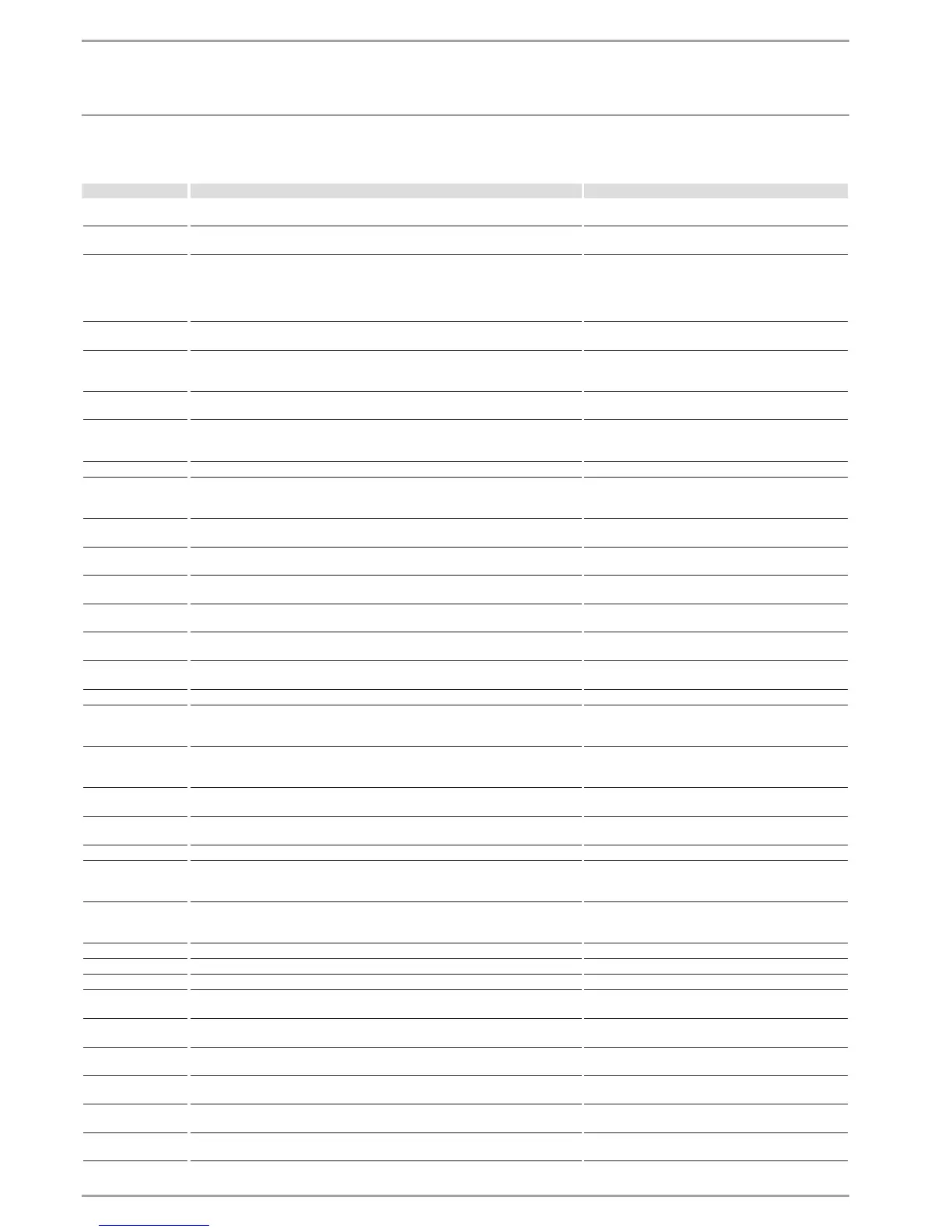

50 | WPM 3 www.stiebel-eltron.com

INSTALLATION

Troubleshooting

Fault list for HP TYPE 4 and 4*

Fault display Reason for fault code being triggered Possible cause of fault / remedy

LOW PRESSURE The minimum low pressure limiter has been triggered (below 1.0 bar for 240 s). Refrigerant escaped. Expansion valve does not open.

Check fan and fuse.

ERR ND PRESSURE Multiple response from the LOW PRESSURE limiter in a defined compressor runt-

ime.

Remove the cause. Then carry out a WPM reset.

MEAN PRESSURE

The minimum mean pressure limiter has been triggered (below 1.0 bar for 240 s).

Refrigerant escaped. Expansion valve does not open.

High pressure compressor shut-off valve does not open.

Non-return valve of the low pressure compressor by-

pass does not open.

Check fan and fuse.

ERR MD PRESSURE Multiple response from the MEAN PRESSURE limiter in a defined compressor runt-

ime.

Remove the cause. Then carry out a WPM reset.

HIGH PRESSURE

The high pressure limiter of the low pressure compressor (switching point 29 bar)

or of the high pressure compressor (switching point 39 bar) has been triggered.

The selected room temperature or heating curve is too high.

Check the flow rate and sensor connection on the heat-

ing side.

Check the selected room temperature or heating curve.

ERR HD PRESSURE Multiple response from the HIGH PRESSURE limiter in a defined compressor runt-

ime.

Remove the cause. Then carry out a WPM reset.

NO OUTPUT

High pressure does not increase significantly above low pressure following com-

pressor start-up and a delay time. (High pressure < low pressure + 2 bar within

120seconds).

Heat pump connection fuse has blown. Remove the

cause. Then carry out a WPM reset.

ERR K OUTPUT Multiple response from the NO OUTPUT limiter in a defined compressor runtime. Remove the cause. Then carry out a WPM reset.

MIN SUPERHEATING

Superheating of the refrigerant at the evaporator outlet or the compressor inlet of

the high pressure compressor for too long below the permissible limit (superheat-

ing is < minimum superheating value for 5 minutes).

Expansion valve or control head not working correctly.

ERR M SUPERHEAT-

ING IWS

Multiple response from the MIN SUPERHEATING limiter in a defined compressor

runtime.

Remove the cause. Then carry out a WPM reset.

REFRIGERANT LOW Unexpectedly high deviation of the expansion valve opening from the pre-control

characteristic.

Refrigerant leak, incorrect expansion valve function

ERR K LOW IWS Multiple response from the REFRIGERANT LOW limiter in a defined compressor

runtime.

Remove the cause. Then carry out a WPM reset.

SPEED DEV COMP ND Speed deviation between set and actual compressor values for a defined time. Inverter or compressor not working correctly. Check the

inverter BUS connection.

I INV V ND Limiter for power interruption to inverter of low pressure compressor has been

triggered.

Value is reset automatically.

If necessary, check the compressor wiring.

SUPERHEATING INV

V ND

Temperature limiter for inverter of low pressure compressor has been triggered. Value is reset automatically.

If necessary, clean the inverter heat sink.

ROTOR KL V ND Rotor stalled limiter for low pressure compressor has been triggered. Value is reset automatically.

START F V ND

Start limiter – fault for low pressure compressor has been triggered.

Mains voltage for compressor supply may be too low

or mains impedance of the compressor supply may be

too high.

OUTL INV V ND

Outlet limiter for low pressure compressor has been triggered.

Mains voltage for compressor supply may be too low

or mains impedance of the compressor supply may be

too high.

I INV V HD Limiter for power failure to inverter of high pressure compressor has been trig-

gered.

Value is reset automatically.

If necessary, check the compressor wiring.

SUPERHEATING INV

V HD

Temperature limiter for inverter of high pressure compressor has been triggered. Value is reset automatically.

If necessary, clean the inverter heat sink.

ROTOR KL V HD Rotor stalled limiter for high pressure compressor has been triggered. Value is reset automatically.

START INV C HP

Start limiter – fault for high pressure compressor has been triggered.

Mains voltage for compressor supply may be too low

or mains impedance of the compressor supply may be

too high.

OUTL INV V HD

Outlet limiter for high pressure compressor has been triggered.

Mains voltage for compressor supply may be too low

or mains impedance of the compressor supply may be

too high.

SPEED DEV COMP HD Speed deviation between set and actual compressor values for a defined time. Inverter or compressor not working correctly.

DEFROST Flow temperature or frost protection temperature < 10 °C or flow rate < 5 l/min. Water flow rate too low, water temperature too low.

ERR DEFROST Multiple response from the DEFROST limiter in a defined compressor runtime. Remove the cause. Then carry out a WPM reset.

HEXADECIMAL

SWITCH

The heat pump type DIP switch of the IWS is set incorrectly. Isolate the heat pump from the power supply and set

the DIP switch correctly.

HD SENSOR MAX The high pressure sensor of the low pressure compressor (27 bar) or the high pres-

sure sensor of the high pressure compressor (37 bar) has responded.

Heating flow rate too low, selected room temperature /

heating curve too high.

MAX HOT GAS Hot gas temperature has exceeded limit (140°C). Injection valve function incorrect, expansion valve func-

tion incorrect, refrigerant leak.

ERR T VOR IWS Sensor value of the flow sensor outside the permissible range. Check sensor, leads and the relevant plug-in connec-

tors, and replace if faulty.

ERR T RUE IWS Sensor value of the return sensor outside the permissible range Check sensor, leads and the relevant plug-in connec-

tors, and replace if faulty.

ERR T FROS IWS Sensor value of the frost protection sensor outside the permissible range. Check sensor, leads and the relevant plug-in connec-

tors, and replace if faulty.

Loading...

Loading...