Operation 4

Procedure in emergencies

6219_003-128

3

Emergency lowering

If the hydraulic controller fails whilst a load

is raised, emergency lowering can be per-

formed. An emergency lowering screw is

located on the valve block (3) for this purpose.

DANGER

There is a risk of fatal injury from

falling loads or parts of the truck being

lowered.

– Do not walk beneath the raised

load.

– Adhere to the steps detailed below.

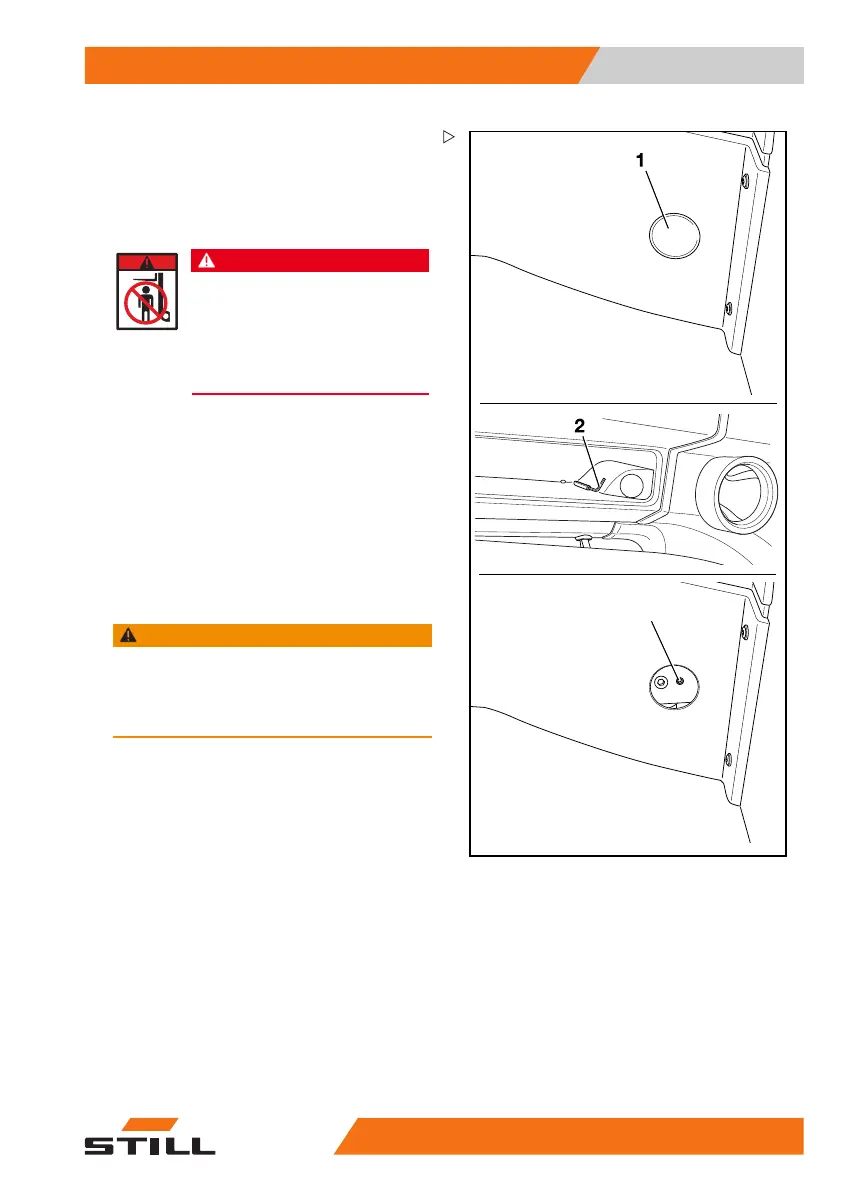

– Remove the lid (1) on the right-hand side

of footwell panelling near the accelerator

pedal.

– Remove the hexagon socket wrench (2)

from the compartment on the right next to

the driver's seat.

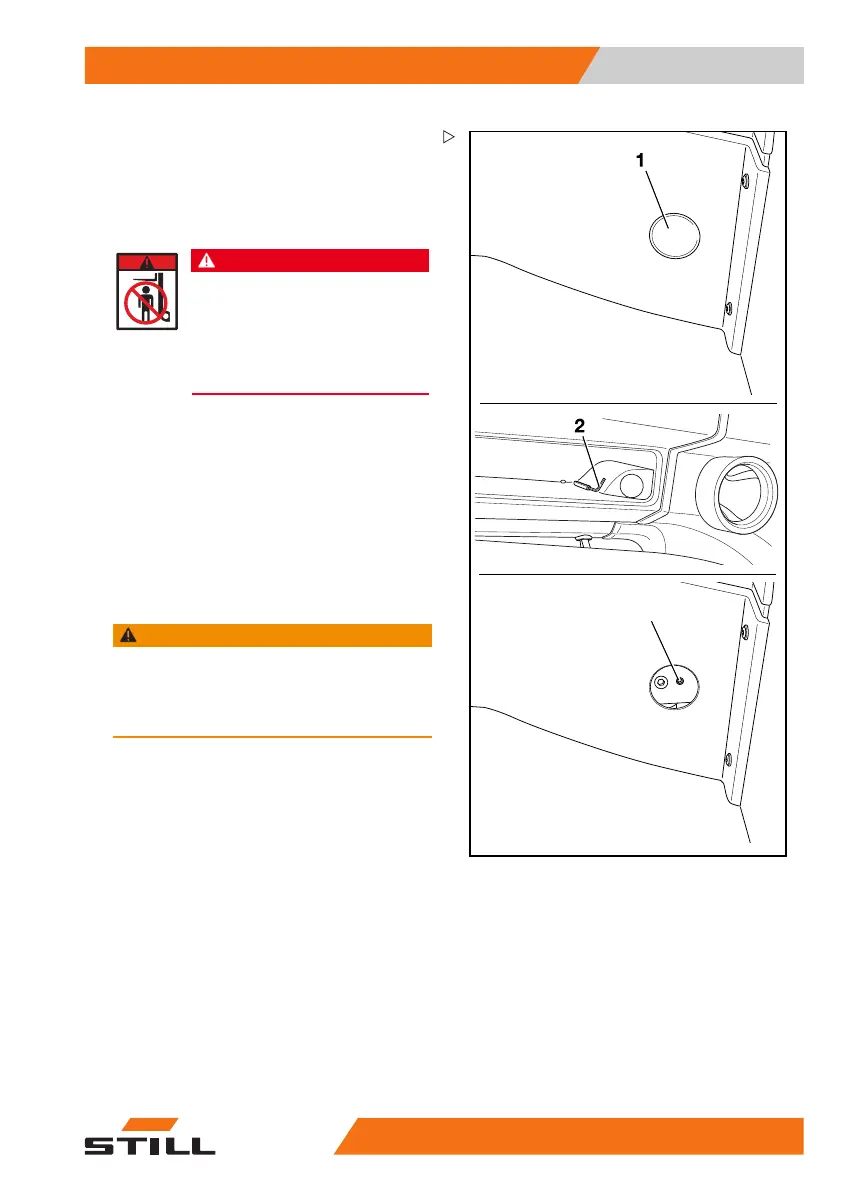

– Using the hexagon socket wrench, turn the

emergency lowering screw (3) a maximum

of 1.5 revolutions to loosen it.

WARNING

The load is lowered!

The lowering speed is regulated by unscrewing the

emergency lowering screw.

– Note the list of points below.

The following applies:

• Tightening torque:

Max. 2.5 Nm

• When unscrewed a little:

The load lowers slowly

• When unscrewed a lot:

The load lowers quickly

After lowering:

– Screw the emergency lowering screw in

again.

– Return the hexagon socket wrench to the

support mounting in the compartment.

– Refit the lid.

563

68011531 EN - 06/2019 - 02 301

Loading...

Loading...