Installation

Size of drive wheel used on sweep depends on size of bin and unload system. A 10” wheel with 4:1

reducer comes standard for all 6” systems and for 8” systems in bins up to 34’ dia. A 17” wheel with 16:1

reducer comes standard for 8” systems in bins 36’ dia. and larger and for all 10” systems.

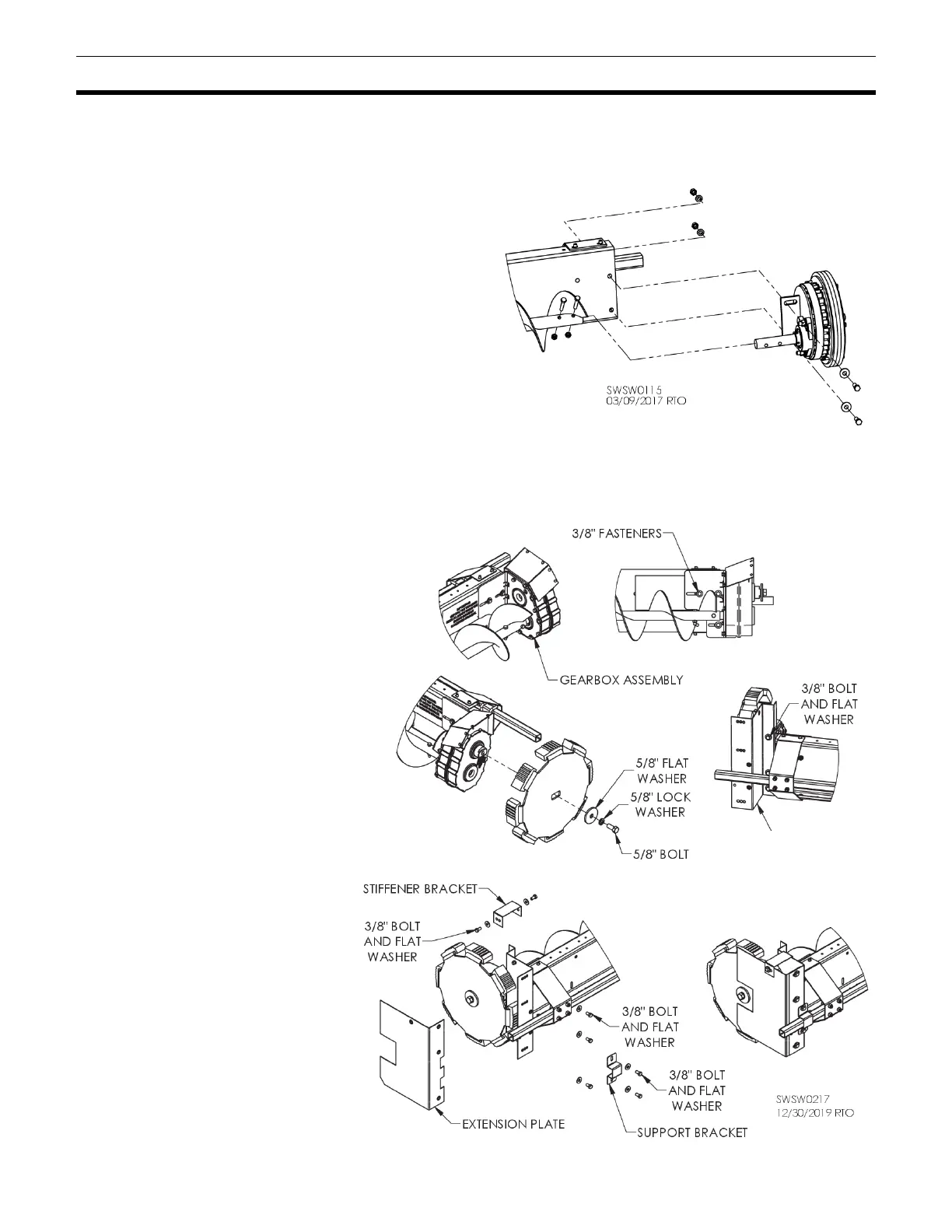

For attachment of 10” wheel, see Fig. 23. Loosely

bolt sweep auger to reduction wheel input shaft using

two 5/16 x 1-3/4” screws (J0570) and two 5/16” lock

nuts (J1010). Loosely bolt mounting bracket to sweep

backboard using two 3/8 x 1” screws (J0606), 3/8”

split lock washers (J1205) and 3/8” hex nuts (J1020)

as shown. Position wheel so it is perpendicular with

backboard and straight up and down. Tighten bolts

connecting shaft to auger, and bolts connecting

mounting bracket to backboard.

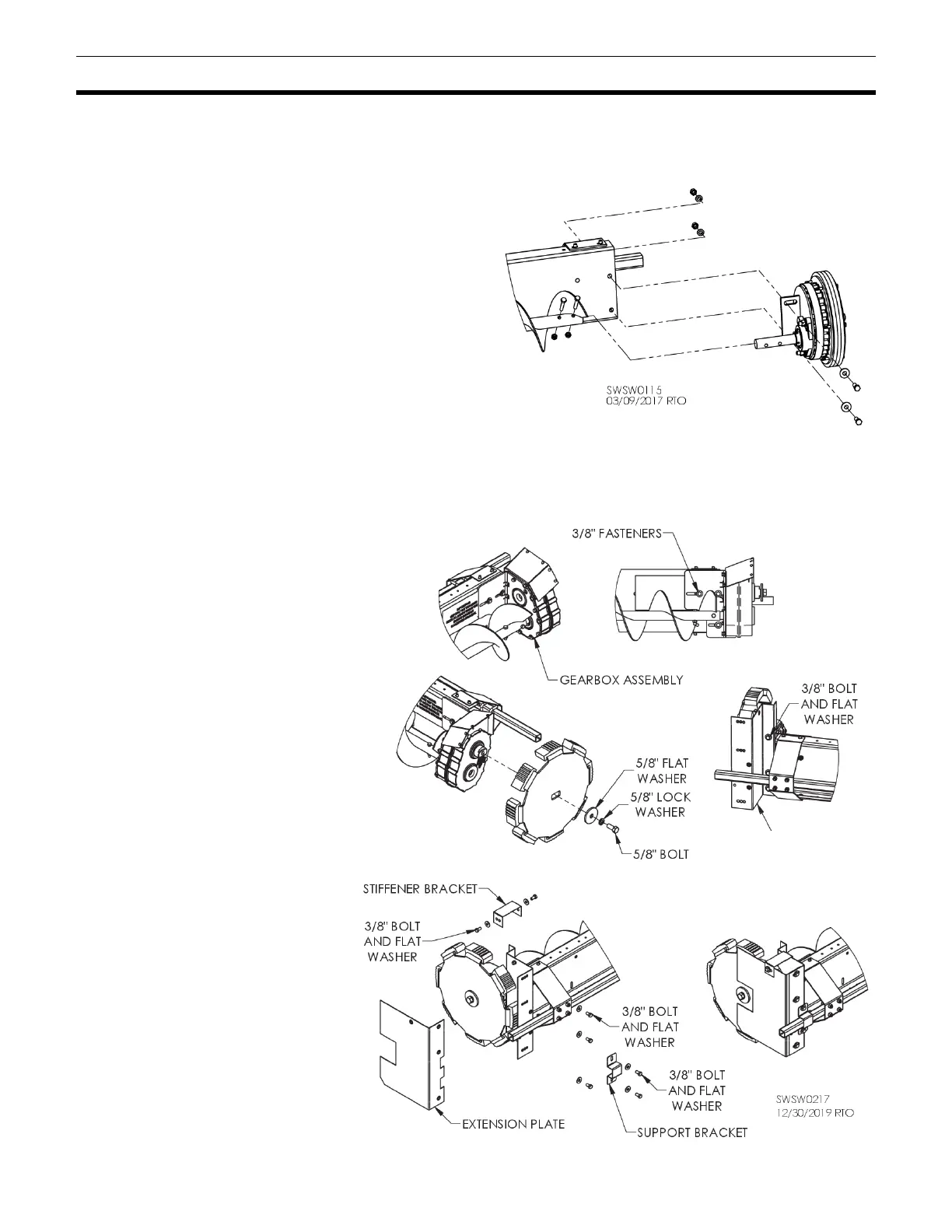

For attachment of 17” wheel, see Fig. 24. Slide gearbox assembly shaft into auger. On 8” system, secure

with 5/16 x 1-3/4” bolts and 5/16” lock nuts. On 10” system, secure with 3/8 x 2-1/4” bolts and 3/8” lock

nuts. NOTICE: Ensure gearbox is straight. Failure to do so may cause auger tube to break.

Bolt gearbox assembly to

backboard using 3/8 x 1” bolts, flat

washers and flange nuts. See Fig.

24.

Remove 5/8” bolt from gearbox

output shaft. Use it to attach drive

wheel as shown in Fig. 25.

Attach grain reclaim shield as

shown in Fig. 25 using 3/8 x 3/4”

bolts, flat washers.

Attach extension plate, support

bracket and stiffener bracket as

shown in Fig. 26 using 3/8 x 3/4”

bolts, flat washers.

NOTE: On reclaim shield there are

three holes in each of the three

sets of holes for mounting

extension plate. Use the middle

hole in each set.

NOTE: If bin has a stirring

machine, trim its down-augers to

avoid contact with sweep and 17”

wheel. Minimum clearance from

any object is 6”.

Loading...

Loading...