16E / 16E-H / 16E-P Spray Gun

44

MAN 96150 EN 01

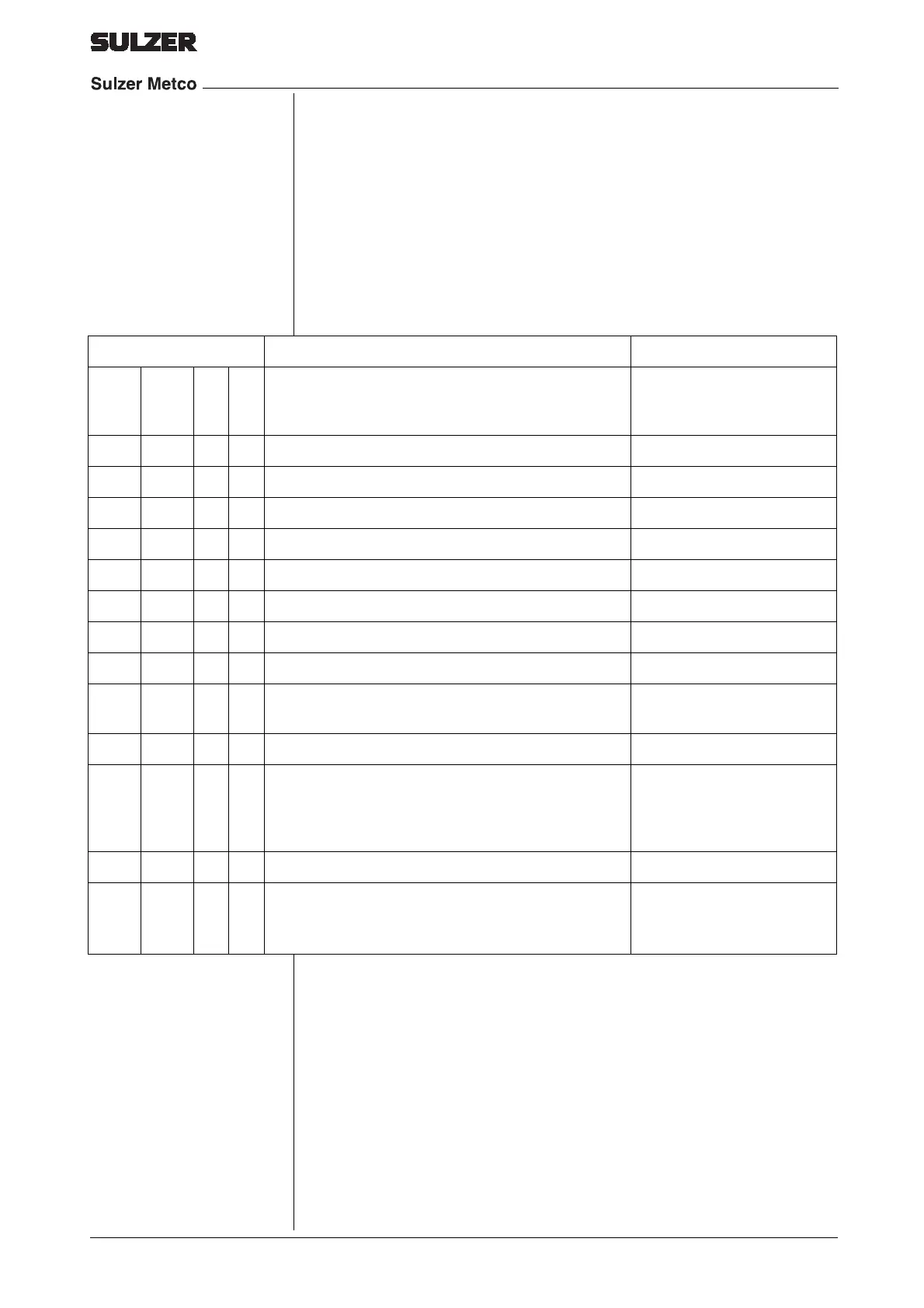

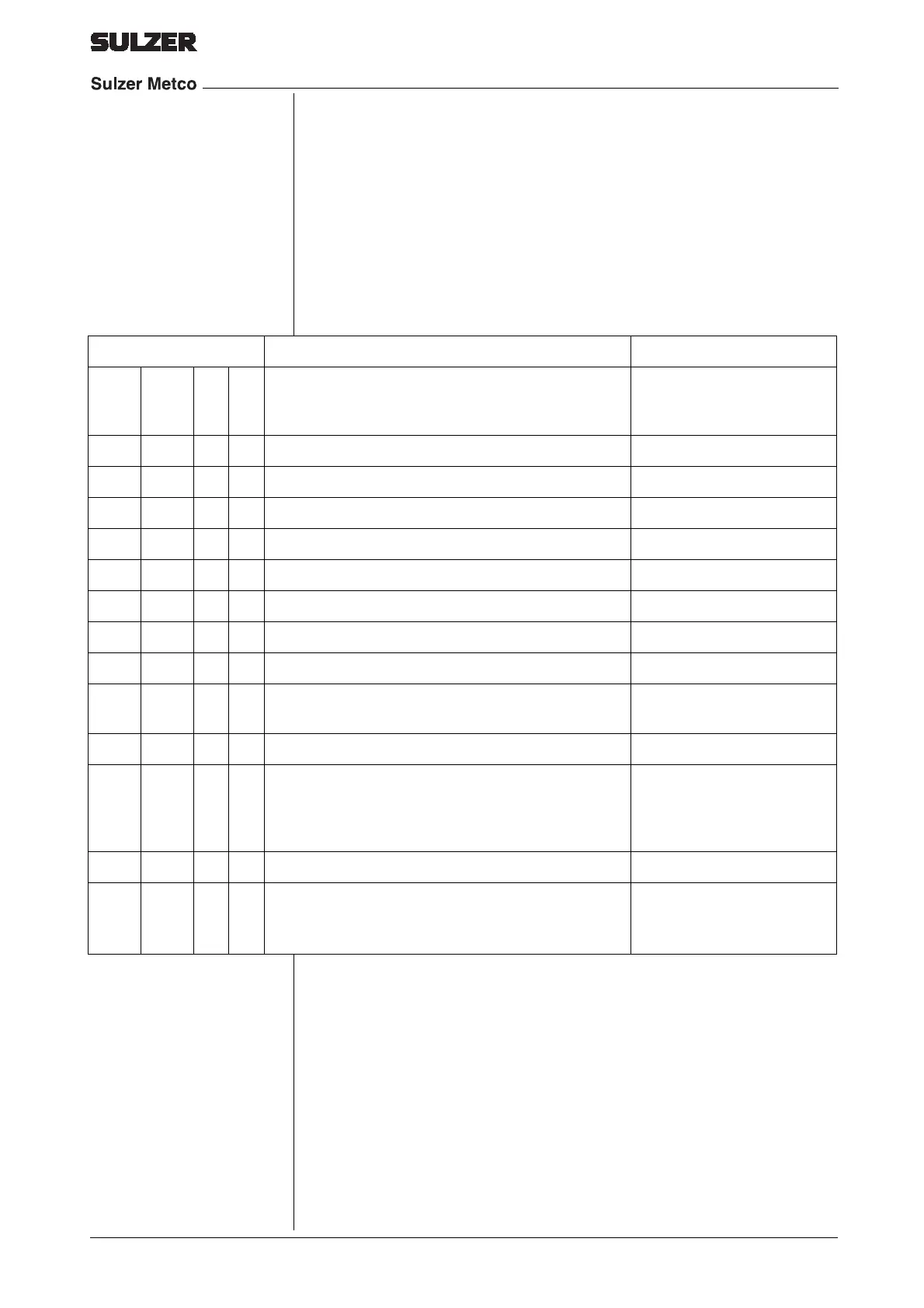

6.7 Scheduled Maintenance

This section provides information to help maximize service life and

performance of the gun.

Speed and load of gun, frequency of lighting, temperature at which

gun operates affect service frequency of the spray gun.

Service Plan

Operating hours Activity Tool

1000 200 40 8

Clean spray gun

Check spray gun and gas supply hoses for dam-

age

Clean durable cloth

1000 200 40 8

Clean drive rolls Brush, compressed air

1000 200 40 8

Clean air cap, wipe out soot

1000 200 40 8

Clean nozzle Cleaning wire kit

1000 200 40

Clean siphon plug Cleaning wire kit

1000 200 40

Oil upper drive roll bushing 2 drops

1000 200 40

Oil upper drive roll carrier hinge 1 drop

1000 200 40

Lube turbine cover bearing Gearlube, 1.5mm strip

1000 200 40

Check lubricant in gear case

1000 200

Clean turbine brake disc and shoe.

Do not lube!

Cleaning solvent

1000 200

Clean and lubricate control ring thread Krytox®

1000 200

Clean turbine shaft oil seal:

- Wash contacting faces of bobbins and washers

- Reassemble dry, except for a thin film Gearlube

on bobbin O-rings

Cleaning solvent

1000

Clean and lubricate gas head valve Krytox®

1000

Complete overhaul of spray gun

(

“Disassembly” on page 50 and “Assembly” on

page 59

)

Loading...

Loading...