40

Stitch Adjustment Method

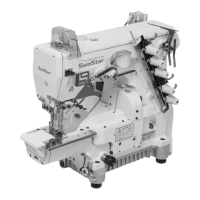

Descending from no.1

toward no.5, the stitch is

getting longer.

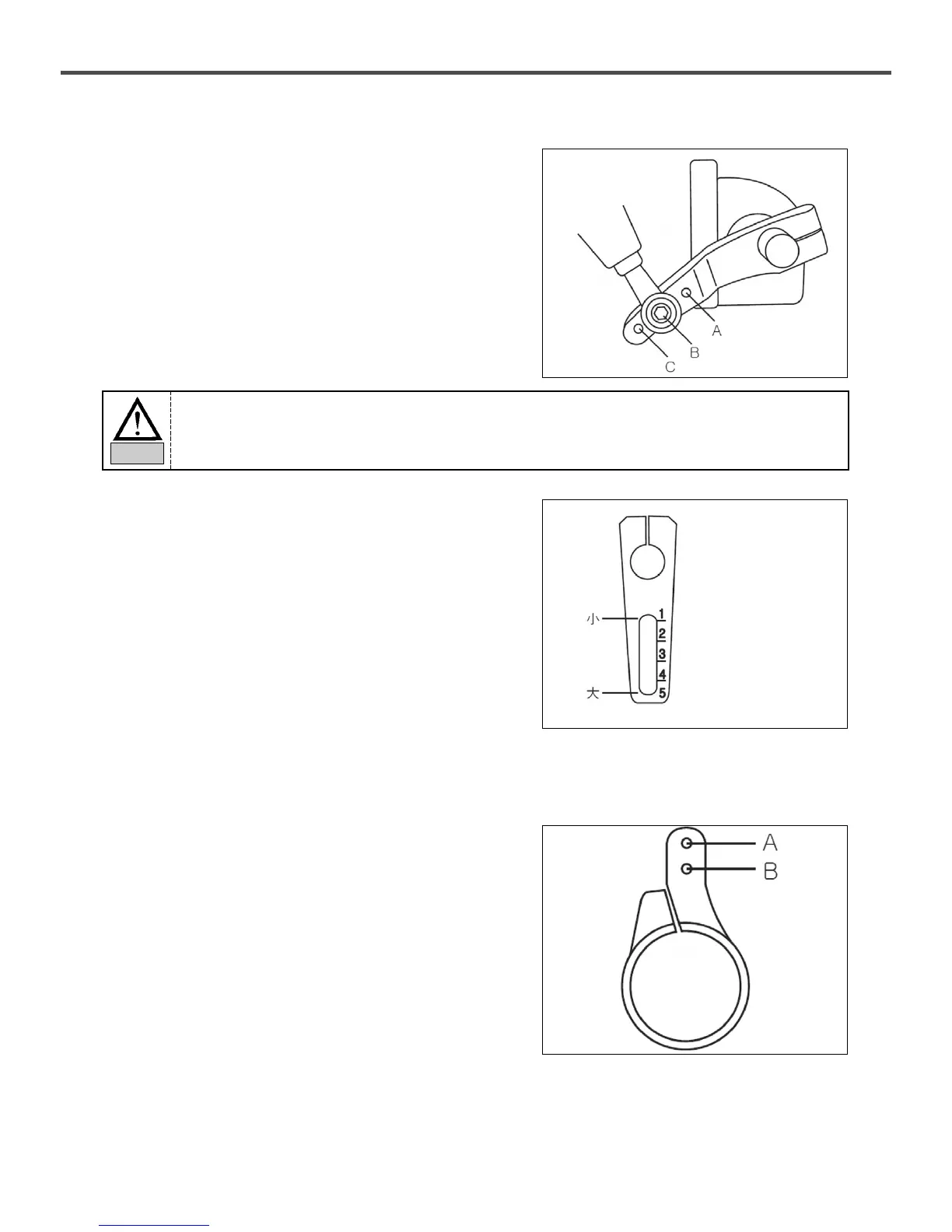

15) Adjustment of Puller Feeding Amount

- Shaft lever(PART NO.12) function can choose the

feeding of roller(quantity of motion/the stitch role of

sawing machine).

A(quantity of motion) : Large=5.2m/m, Small=2.3m/m

B(quantity of motion) : Large=4m/m, Small=2m/m

C(quantity of motion) : Large=3.3m/m, Small=1.3m/m

16) Speed Lever Stitch Length Adjustment

- The shaft lever(PART NO.25) stitch is adjusted as the

scale is widened and it can be adjusted by changing the

setting position.

- Timing adjustment

Unfasten part no.13, shake no.25 back and forth more

than 5 times.

After the position of bearing is settled, adjust to the place

which the arrow direction is matched and fix the part no.13.

(See Decelerator Timing Adjustment of the manuals)

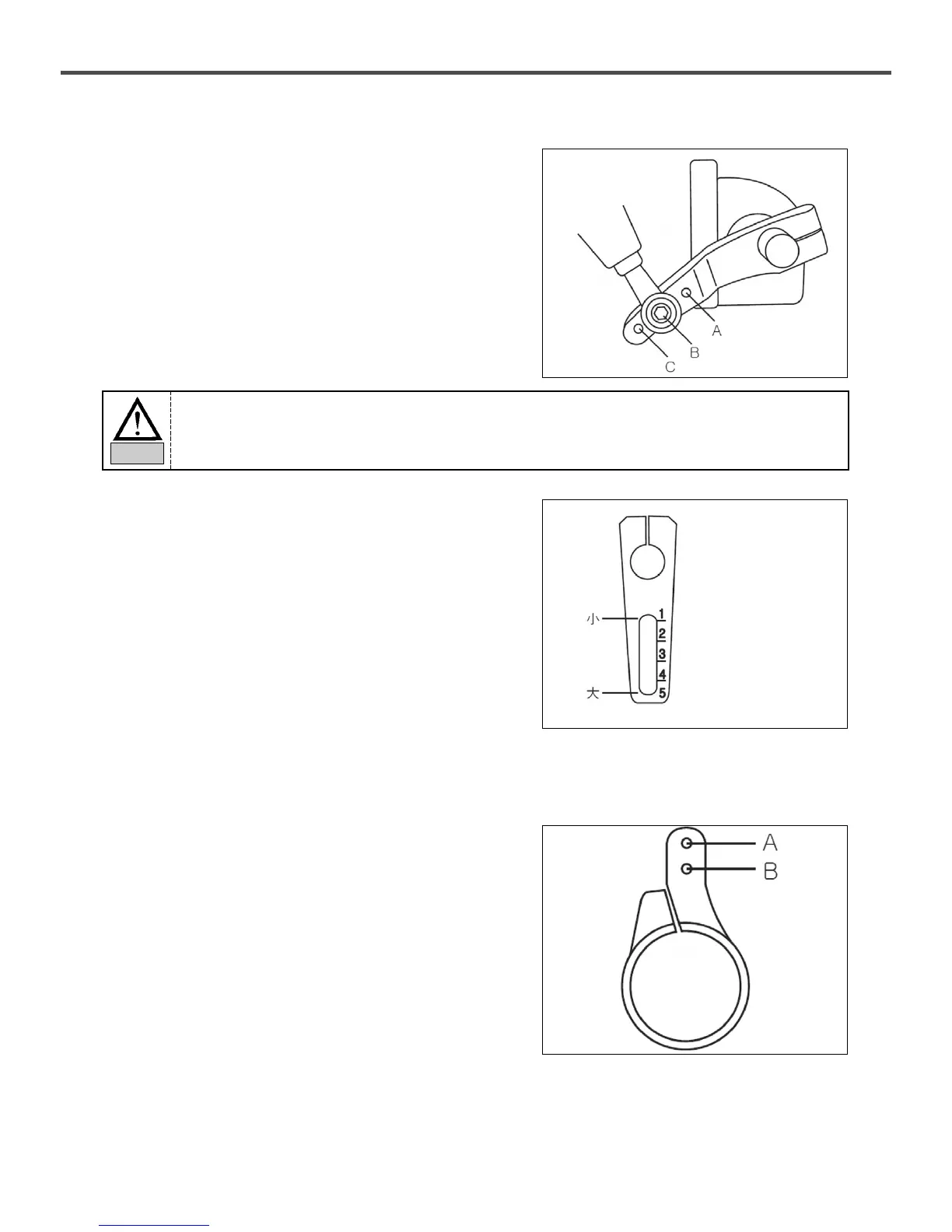

17) P.S.W-I Stitch Length Adjustment

* LRP Type(PART NO.66), SRP Type(PART NO.55)

Generally use by fixing to the standard position (A) part

but in case of using the stitch longer, position (B) can be used.

In case of moving the position of shaft lever(PART NO.12),

be sure that the power switch of M/C is in the OFF position and the power cord is unplugged.

Caution

Loading...

Loading...