ENGINE GENERAL INFORMATION AND DIAGNOSIS (TBI FOR G10) 6-49

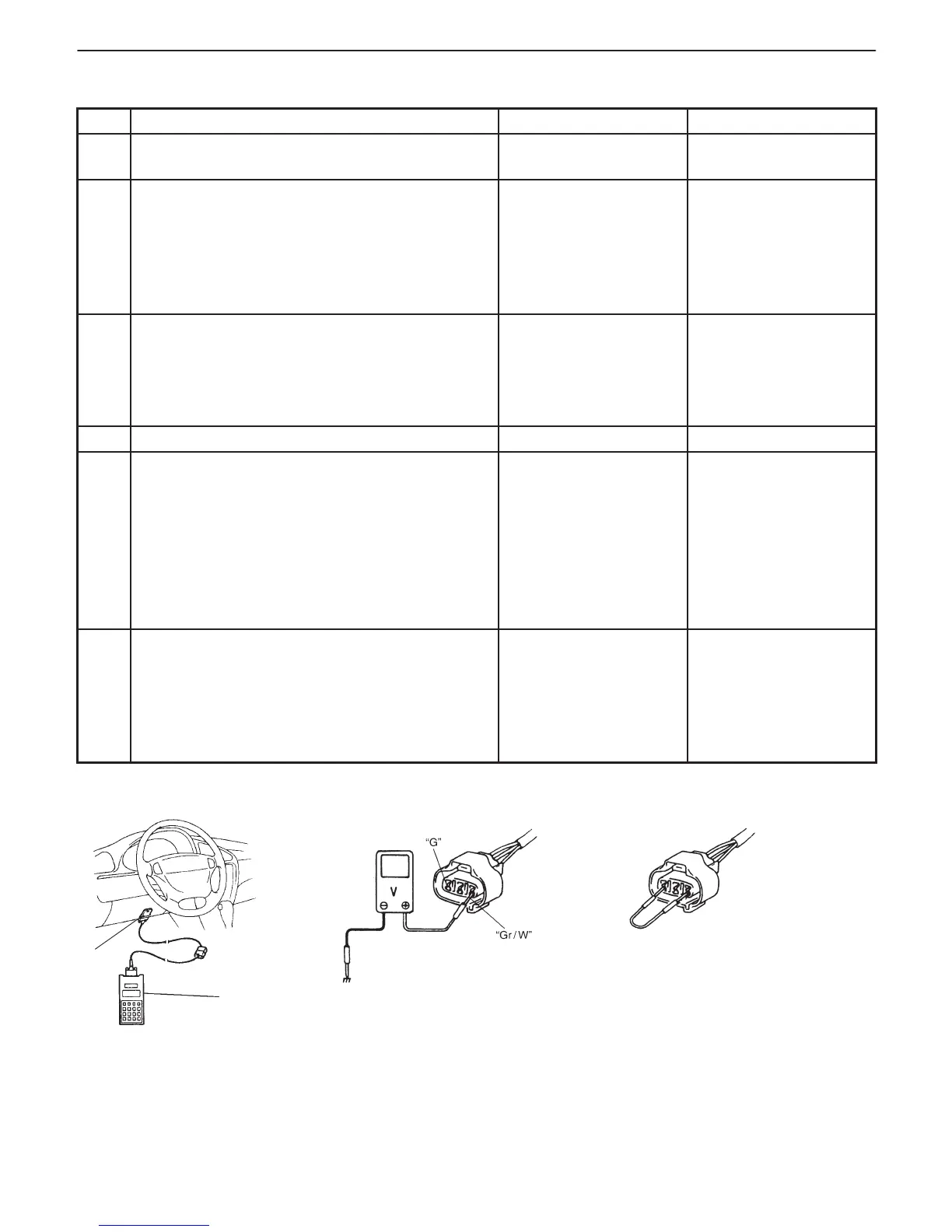

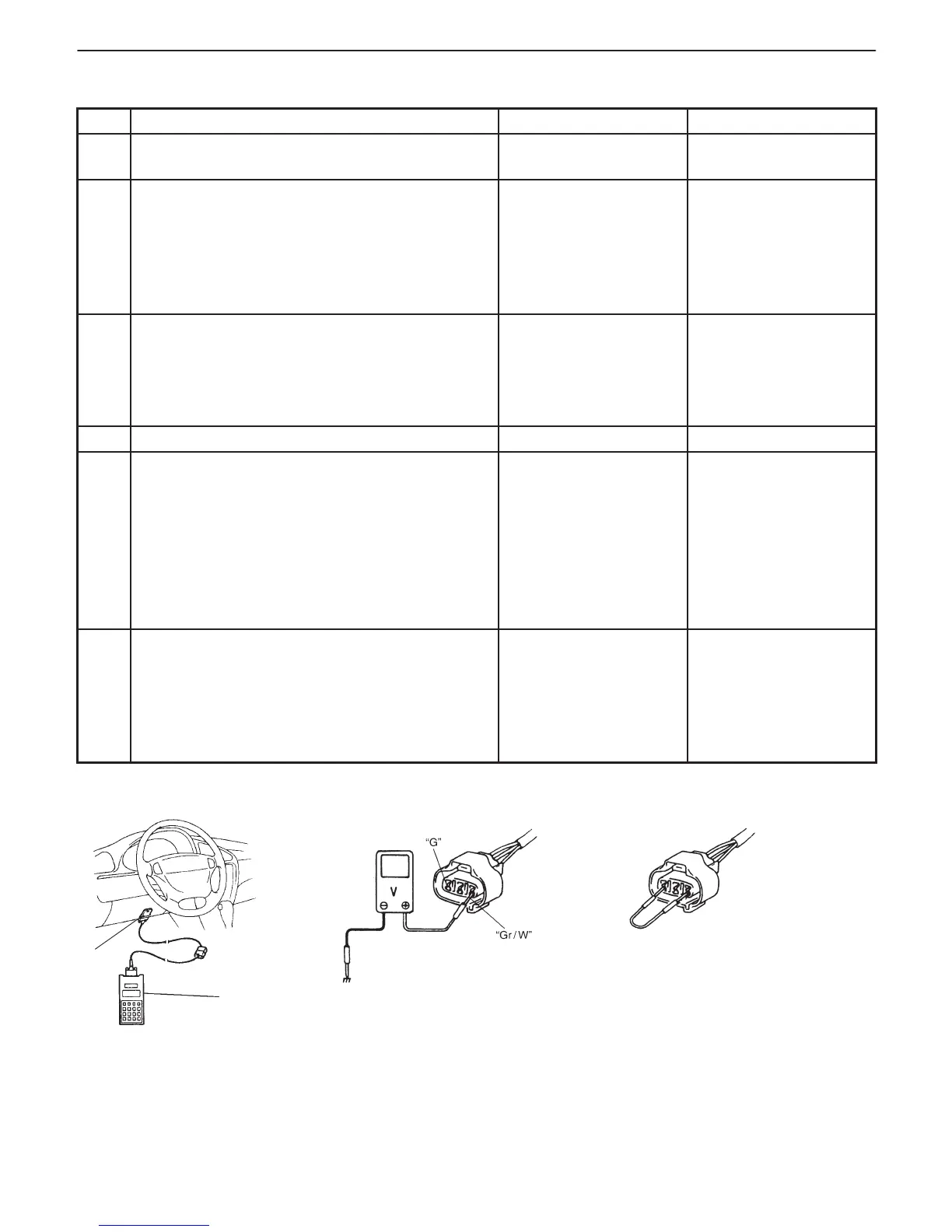

Fig. 1 for Step 2 Fig. 2 for Step 3 Fig. 3 for Step 4

Scan tool

DLC

INSPECTION

STEP ACTION YES NO

1 Was “ENGINE DIAG. FLOW TABLE” performed? Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Check ECT Sensor and Its Circuit.

1) Connect scan tool with ignition switch OFF.

2) Turn ignition switch ON.

3) Check engine coolant temp. displayed on scan

tool. See Fig. 1.

Is –40_C (–40_F) or 119_C (246_F) indicated?

Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection”

in Section 0 A.

3 Check Wire Harness.

1) Disconnect ECT sensor connector.

2) Check engine coolant temp. displayed on scan

tool.

Is –40_C (–40_F) indicated?

Replace ECT sensor. “Gr/W” wire shorted to

ground.

If wire is OK, substitute

a known-good ECM

(PCM) and recheck.

4 Does scan tool indicate –40_C (–40_F) at Step 2. Go to Step 6. Go to Step 5.

5 Check Wire Harness.

1) Disconnect ECT sensor connector with

ignition switch OFF.

2) Check for proper connection to ECT sensor at

“G” and “Gr/W” wire terminals.

3) If OK, then with ignition switch ON, is voltage

applied to “G” wire terminal about 4 – 6 V?

See Fig. 2.

Go to Step 4. “Gr/W” wire open or

shorted to power, or

poor C01-7 connection.

If wire and connection

are OK, substitute a

known-good ECM

(PCM) and recheck.

6 Check Wire Harness.

1) Using service wire, connect ECT sensor

connector terminals. See Fig. 3.

2) Turn ignition switch ON and check engine

coolant temp. displayed on scan tool.

Is 119_C (246_F) indicated?

Replace ECT sensor. “G” wire open or

poor C01-9 connection.

If wire and connection

are OK, substitute a

known-good ECM

(PCM) and recheck.

Loading...

Loading...