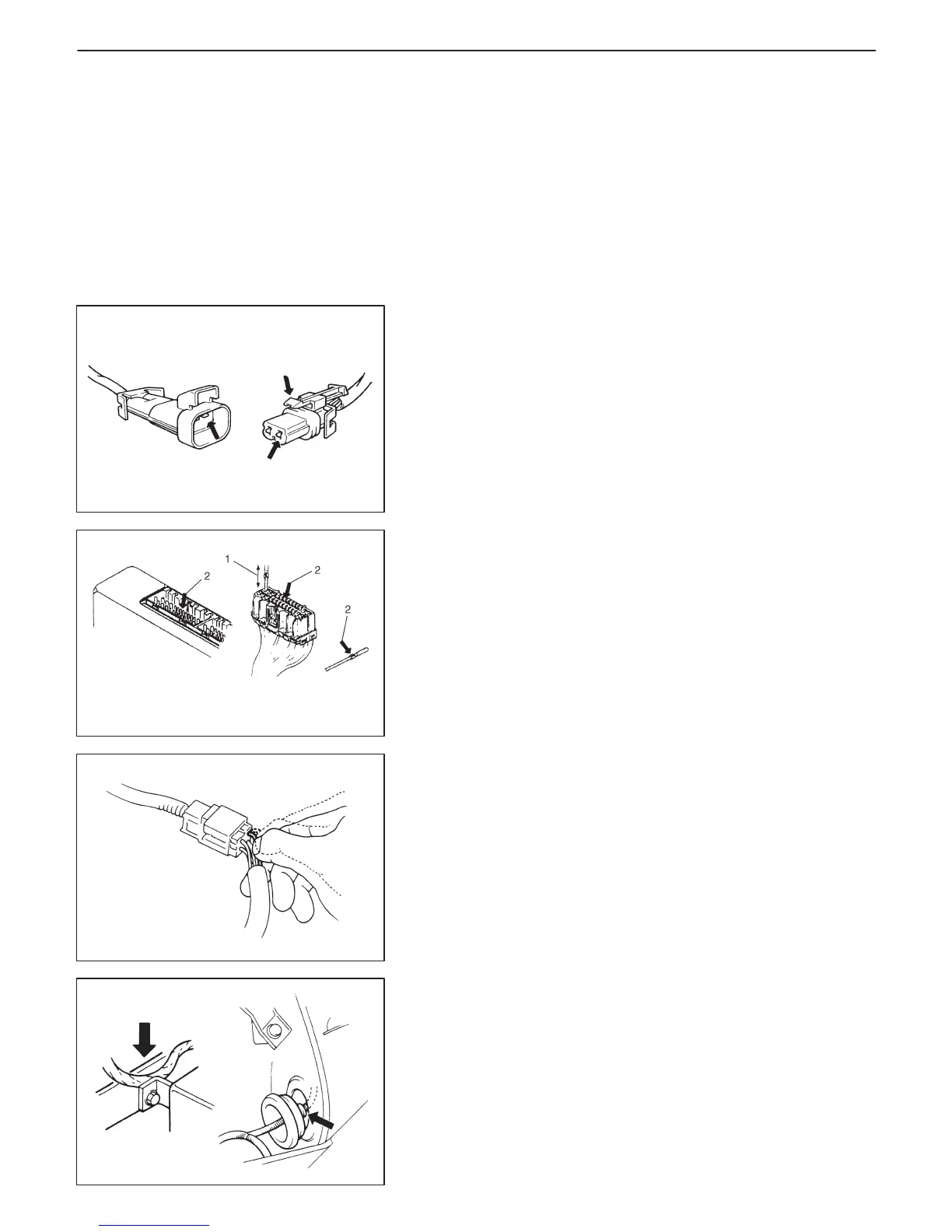

1. Check contact tension by inserting and removing just once

2. Check each terminal for bend and proper alignment

GENERAL INFORMATION 0A-15

INTERMITTENT AND POOR CONNECTION

Most intermittent are caused by faulty electrical connections or wir-

ing, although a sticking relay or solenoid can occasionally be at

fault. When checking it for proper connection, perform careful

check of suspect circuits for:

D Poor mating of connector halves, or terminals not fully seated in

the connector body (backed out).

D Dirt or corrosion on the terminals. The terminals must be clean

and free of any foreign material which could impede proper termi-

nal contact. However, cleaning the terminal with a sand paper or

the like is prohibited.

D Damaged connector body, exposing the terminals to moisture

and dirt, as well as not maintaining proper terminal orientation

with the component or mating connector.

D Improperly formed or damaged terminals.

Check each connector terminal in problem circuits carefully to en-

sure good contact tension by using the corresponding mating ter-

minal.

If contact tension is not enough, reform it to increase contact ten-

sion or replace.

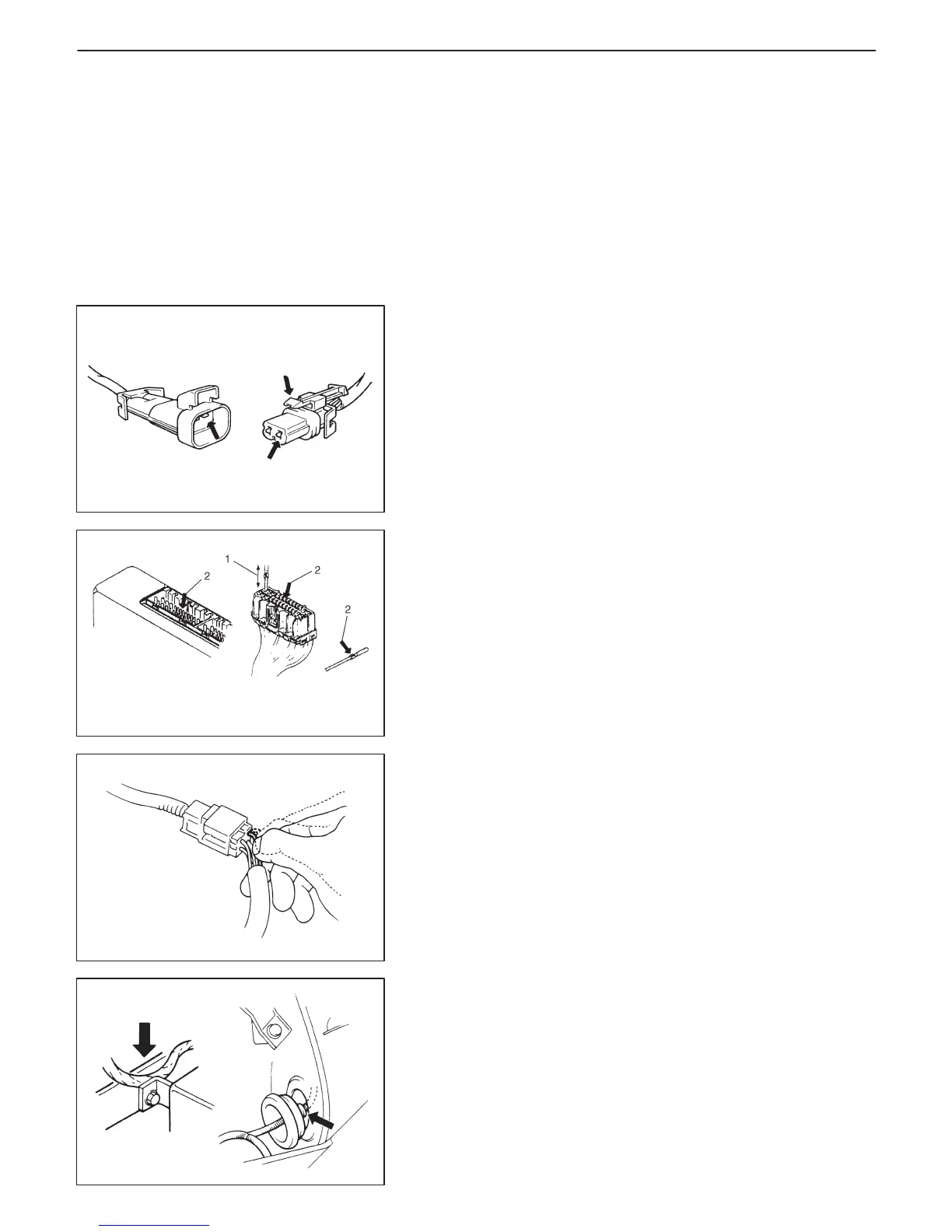

D Poor terminal-to-wire connection.

Check each wire harness in problem circuits for poor connection

by shaking it by hand lightly. If any abnormal condition is found,

repair or replace.

D Wire insulation which is rubbed through, causing an intermittent

short as the bare area touches other wiring or parts of the vehicle.

D Wiring broken inside the insulation. This condition could cause

continuity check to show a good circuit, but if only 1 or 2 strands

of a multi-strand-type wire are intact, resistance could be far too

high.

If any abnormality is found, repair or replace.

Loading...

Loading...