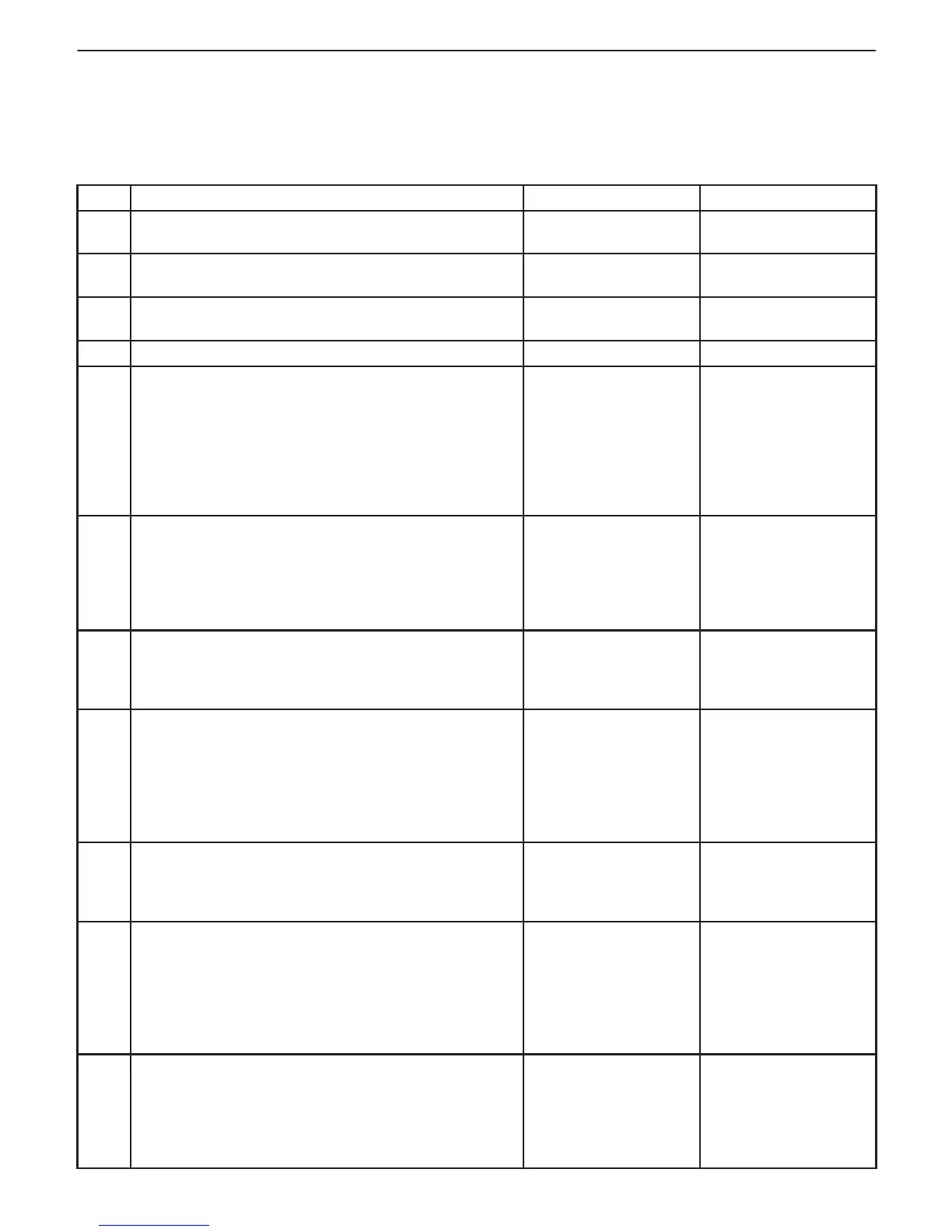

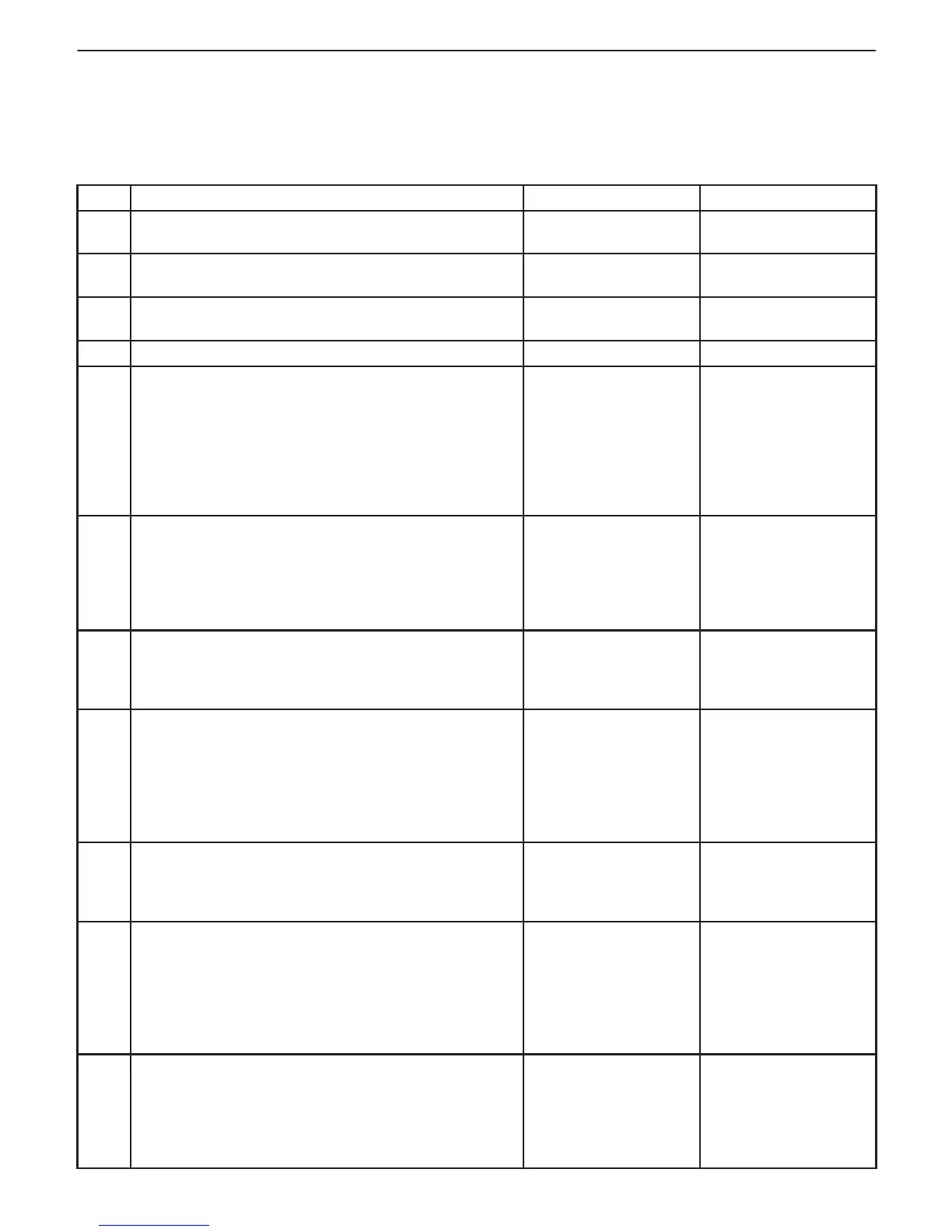

6-20 ENGINE GENERAL INFORMATION AND DIAGNOSIS (TBI FOR G10)

ENGINE BASIC INSPECTION

This check is very important for troubleshooting when ECM (PCM) has detected no DTC and no abnormality has

been found in visual inspection.

Follow the flow table carefully.

STEP

ACTION YES NO

1 Was “ENGINE DIAG. FLOW TABLE” performed? Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Check battery voltage.

Is it 11 V or more?

Go to Step 3. Charge or replace

battery.

3 Is engine cranked? Go to Step 4. Go to “DIAGNOSIS”

in Section 6G.

4 Does engine start? Go to Step 5. Go to Step 7.

5 Check idle speed as follows.

1) Warm up engine to normal operating temp.

2) Shift transmission to neutral position for M/T

(“P” position for A/T).

3) All of electrical loads are switched off.

4) Check engine idle speed with scan tool.

See Fig. 1.

Is it 800 – 900 r/min.?

Go to Step 6. Go to “ENGINE

DIAGNOSIS TABLE”.

6 Check ignition timing as follows.

1) Select “MISC” mode on SUZUKI scan tool and

fix ignition timing to initial one. See Fig. 2.

2) Using timing light (1), check initial ignition timing.

See Fig. 3.

Is it 5_ ± 3_ BTDC at specified idle speed?

Go to “ENGINE

DIAGNOSIS TABLE”.

Check ignition control

related parts referring

to Section 6F.

7 Check immobilizer system malfunction as follows.

1) Check immobilizer indicator lamp for flashing.

Is it flashing when ignition switch is turned to ON

position?

Go to “DIAGNOSIS” in

Section 8A.

Go to Step 8.

8 Check fuel supply as follows.

1) Check to make sure that enough fuel is filled in fuel

tank.

2) Turn ON ignition switch for 2 seconds and then

OFF. See Fig. 4.

Is fuel return pressure (returning sounds) felt from fuel

feed hose (1) when ignition switch is turned ON?

Go to Step 10. Go to Step 9.

9 Check fuel pump for operating.

1) Was fuel pump operating sound heard from fuel

filler for about 2 seconds after ignition switch ON

and stop?

Go to “DIAG. FLOW

TABLE B-3”.

Go to “DIAG. FLOW

TABLE B-2”.

10 Check ignition spark as follows.

1) Disconnect injector coupler.

2) Remove spark plugs and connect them to high

tension cords.

3) Ground spark plugs.

4) Crank engine and check if each spark plug sparks.

Is it in good condition?

Go to Step 11. Go to “DIAGNOSIS”

in Section 6F.

11 Check fuel injector for operation as follows.

1) Install spark plugs and connect injector

connectors.

2) Check that fuel is injected out in conical shape

from fuel injector when cranking.

Is it in good condition?

Go to “ENGINE

DIAGNOSIS TABLE”.

Go to “DIAG. FLOW

TABLE B-1”.

Loading...

Loading...