ENGINE GENERAL INFORMATION AND DIAGNOSIS (TBI FOR G10) 6-75

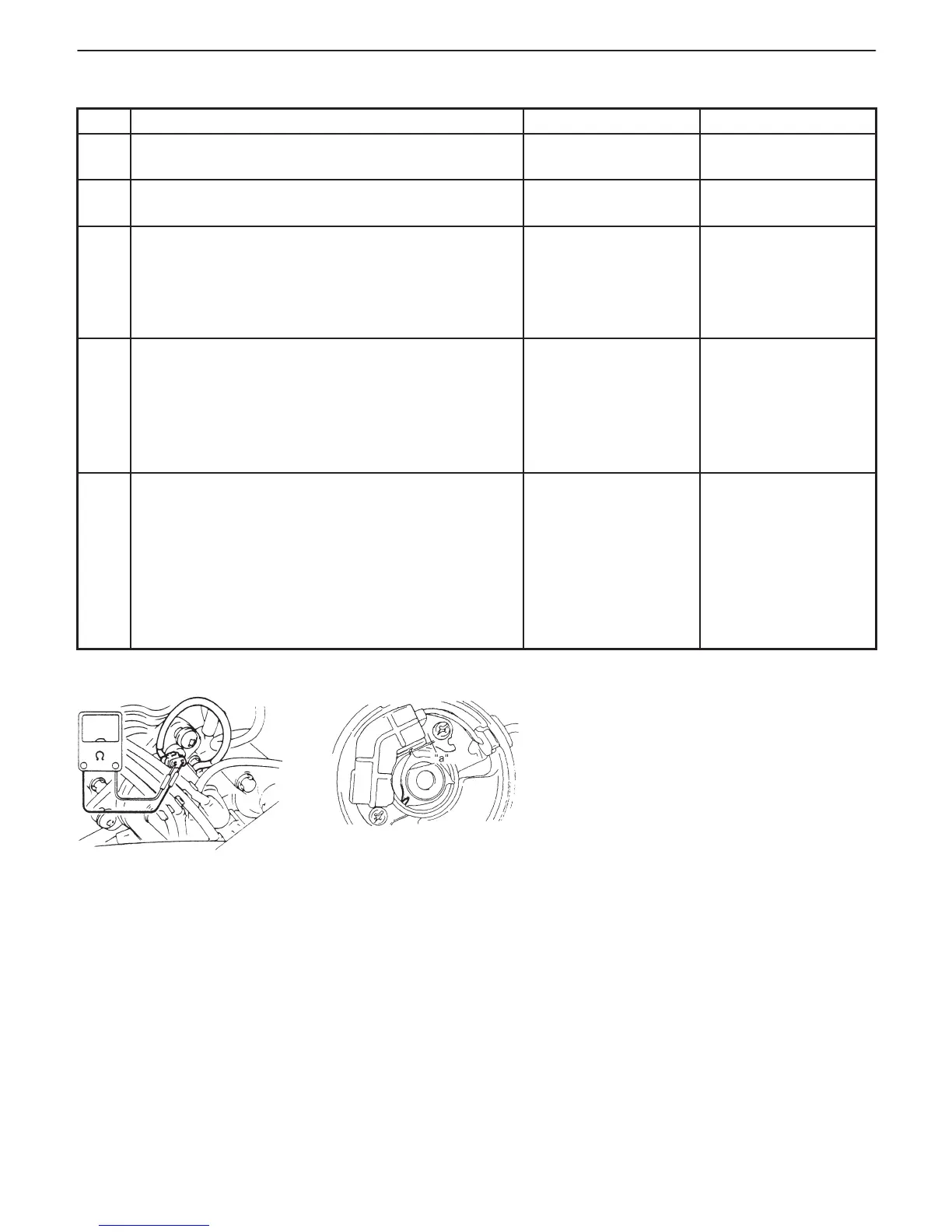

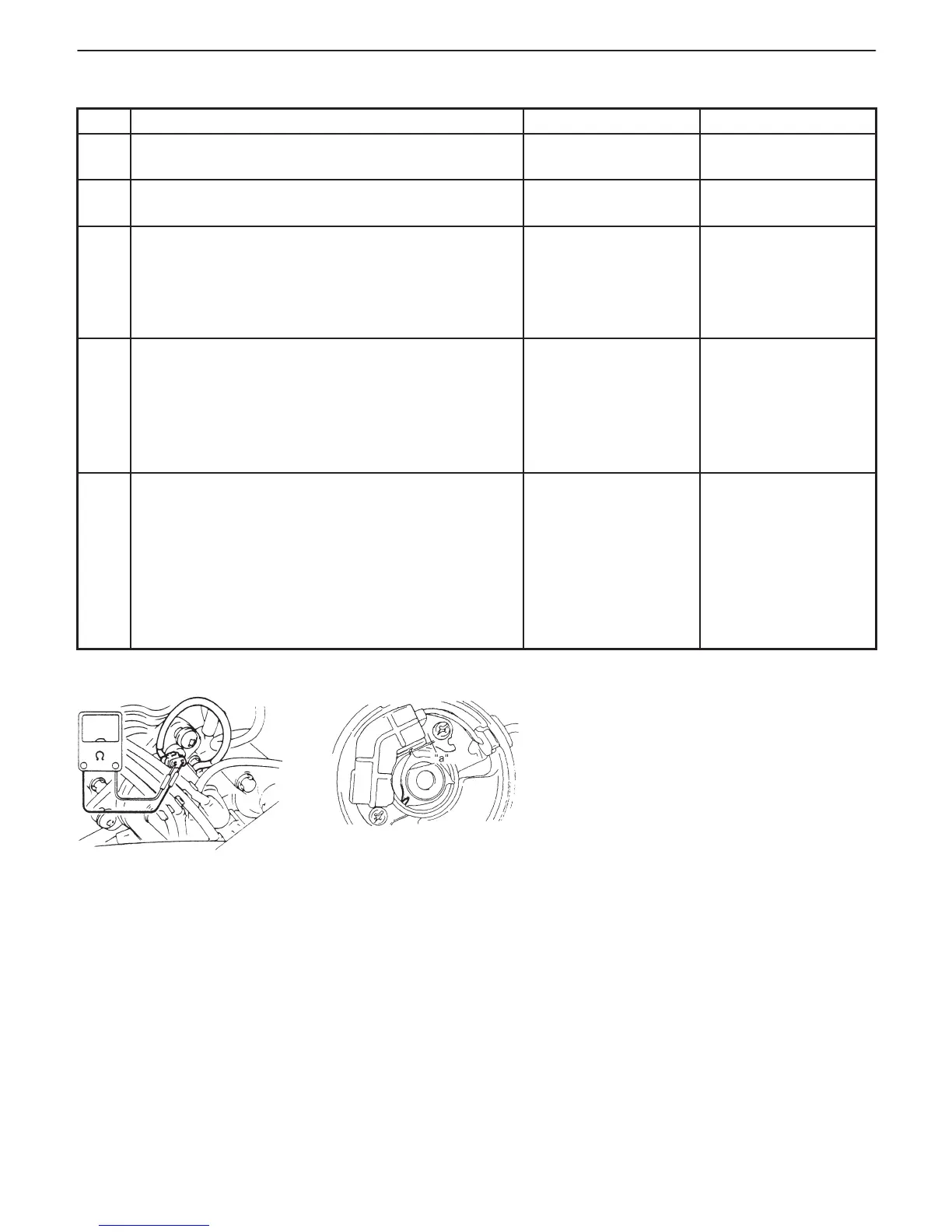

Fig. 1 for Step 3 Fig. 2 for Step 5

“a”: Air gap

INSPECTION

STEP ACTION YES NO

1 Was “ENGINE DIAG. FLOW TABLE” performed? Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Is DTC P1500 (Engine starter signal circuit

malfunction) detected?

Go to DTC P1500

Diag. Flow Table.

Go to Step 3.

3 Check CMP Sensor for Resistance.

1) Measure resistance of CMP sensor by referring to

“CMP SENSOR (PICK UP COIL) RESISTANCE”

in SECTION 6F.

Is resistance within specified value?

Go to Step 4. Faulty CMP sensor.

4 Check Wire Harness.

1) With ignition switch at OFF position, disconnect

ECM (PCM) electrical connectors.

2) Measure resistance from terminal “C01-2” to

“C01-10” of ECM (PCM) connector. See Fig. 1.

Is resistance within 185 – 275 Ω at 20_C (68_F)?

Go to Step 5. “W” or “Or” wire open

or short.

Poor connection of

CMP sensor

connector terminal.

5 Check Air Gap Between Rotor Tooth and Sensor. See

Fig. 2.

1) Remove Distributor cap.

2) Visually inspect CMP sensor signal rotor for

damage.

3) Measure air gap by referring “SIGNAL ROTOR

AIR GAP” in Section 6F.

Was any damage found?

Faulty CMP sensor

signal rotor.

Poor connection of

ECM (PCM)

connector terminal.

If OK, substitute a

known-good ECM

(PCM) and recheck

CMP.

Loading...

Loading...