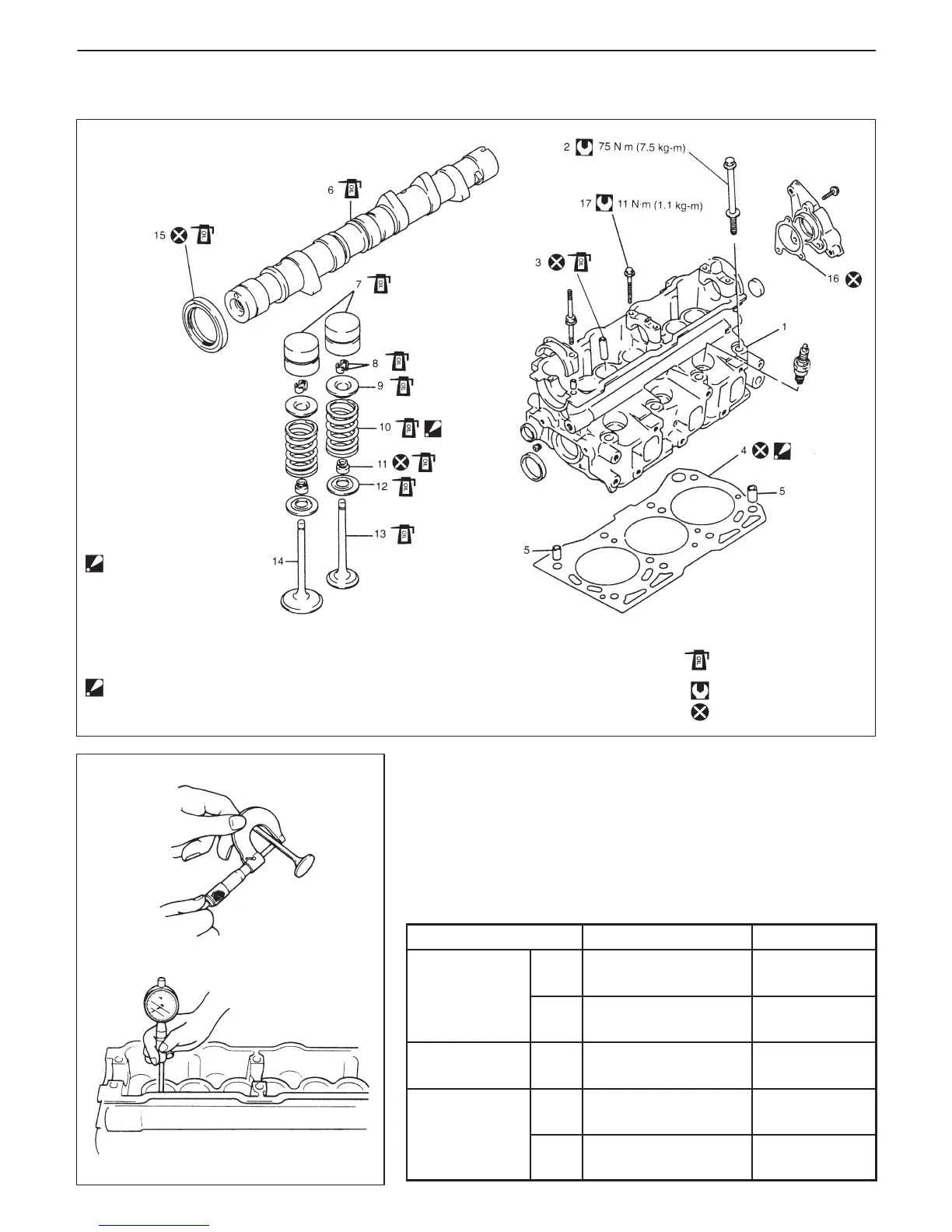

1. Cylinder head

2. Cylinder head bolt

3. Valve guide

4. Cylinder head gasket:

“TOP” mark provided on

gasket comes to crankshaft

pulley side, facing up

(toward cylinder head side).

5. Pin

6. Camshaft

7. Valve lash adjuster

8. Valve cotters

9. Valve spring retainer

10. Valve spring:

Be sure to position spring in place with

its bottom end (small-pitched) facing the

bottom (valve spring seat side).

11. Valve stem seal

12. Valve spring seat

13. Exhaust valve

14. Intake valve

15. Oil seal

16. Gasket

17. Camshaft housing bolt

: Tightening Torque

: Do not reuse

: Apply engine oil to sliding

: surfaces of each part.

ENGINE MECHANICAL (G10, 1-CAM 6-VALVES ENGINE) 6A-21

VALVES AND CYLINDER HEAD

INSPECTION

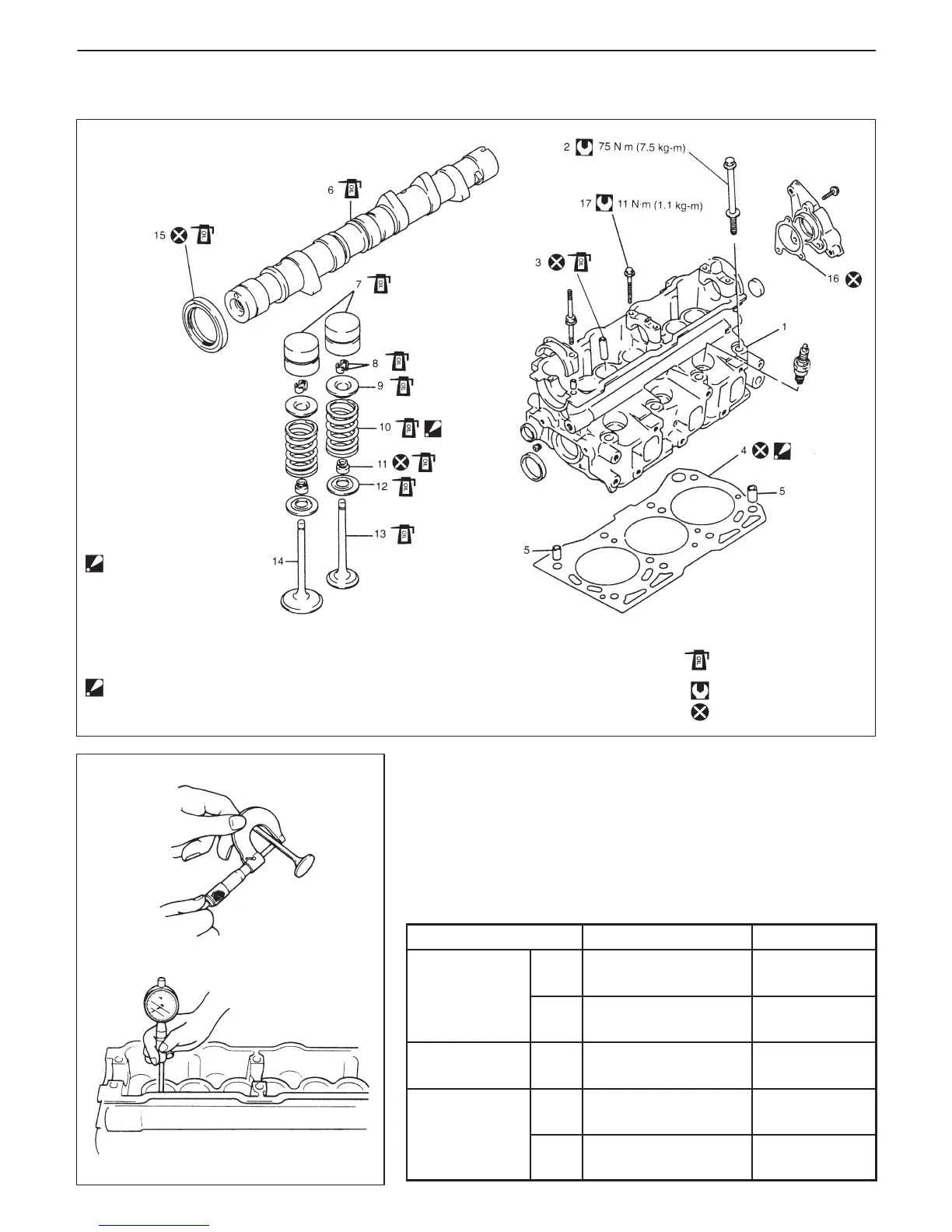

Valve Guides

Using a micrometer and bore gauge, take diameter readings on

valve stems and guides to check stem-to-guide clearance.

Be sure to take reading at more than one place along the length of

each stem and guide.

If clearance exceeds limit, replace valve and valve guide.

Item

Standard Limit

Valve stem

In

5.457 – 5.480 mm

(0.2148 – 0.2157 in.)

———

diameter

Ex

5.440 – 5.455 mm

(0.2142 – 0.2148 in.)

———

Valve guide

I.D.

In &

Ex

5.500 – 5.512 mm

(0.2165 – 0.2170 in.)

———

Stem-to-

Loading...

Loading...