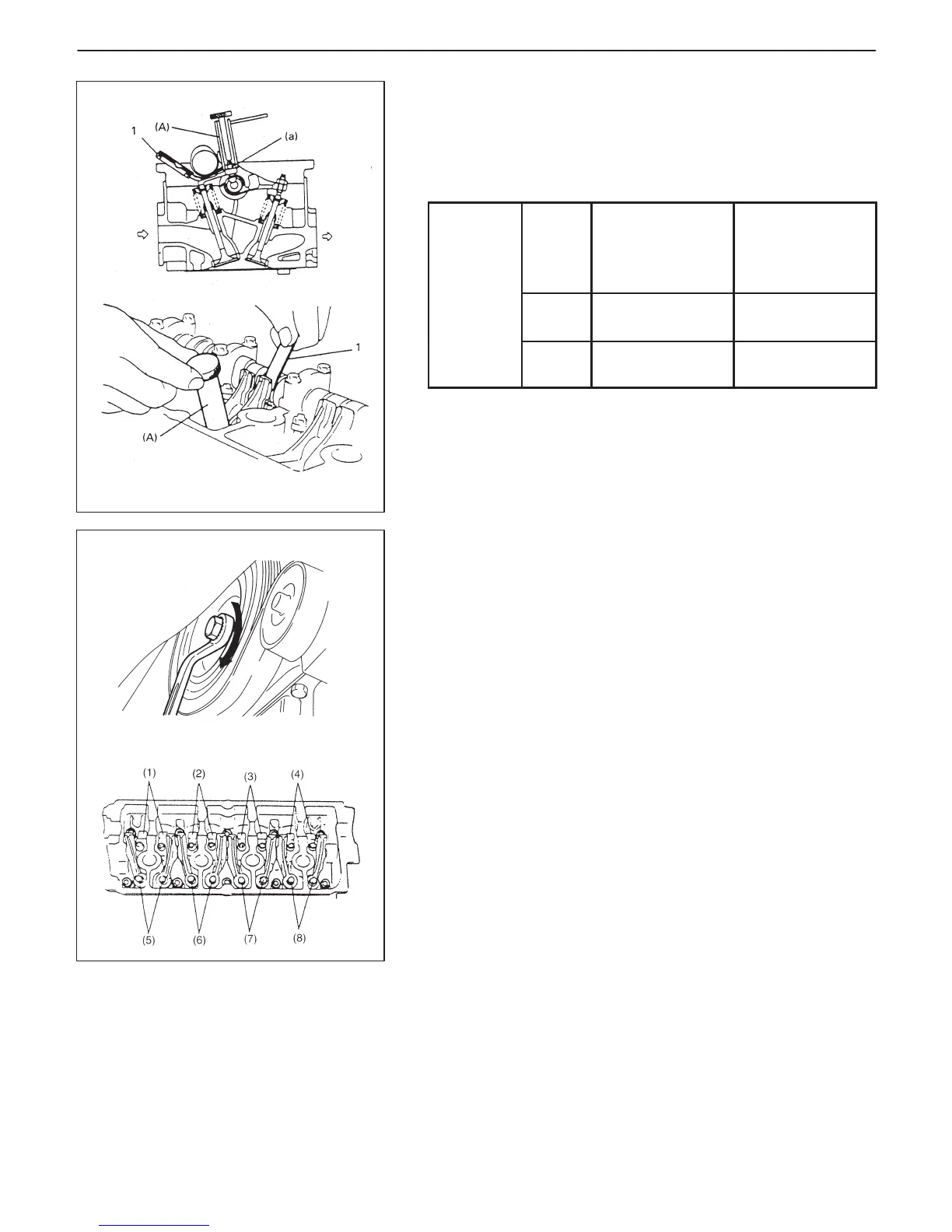

1. Thickness gauge

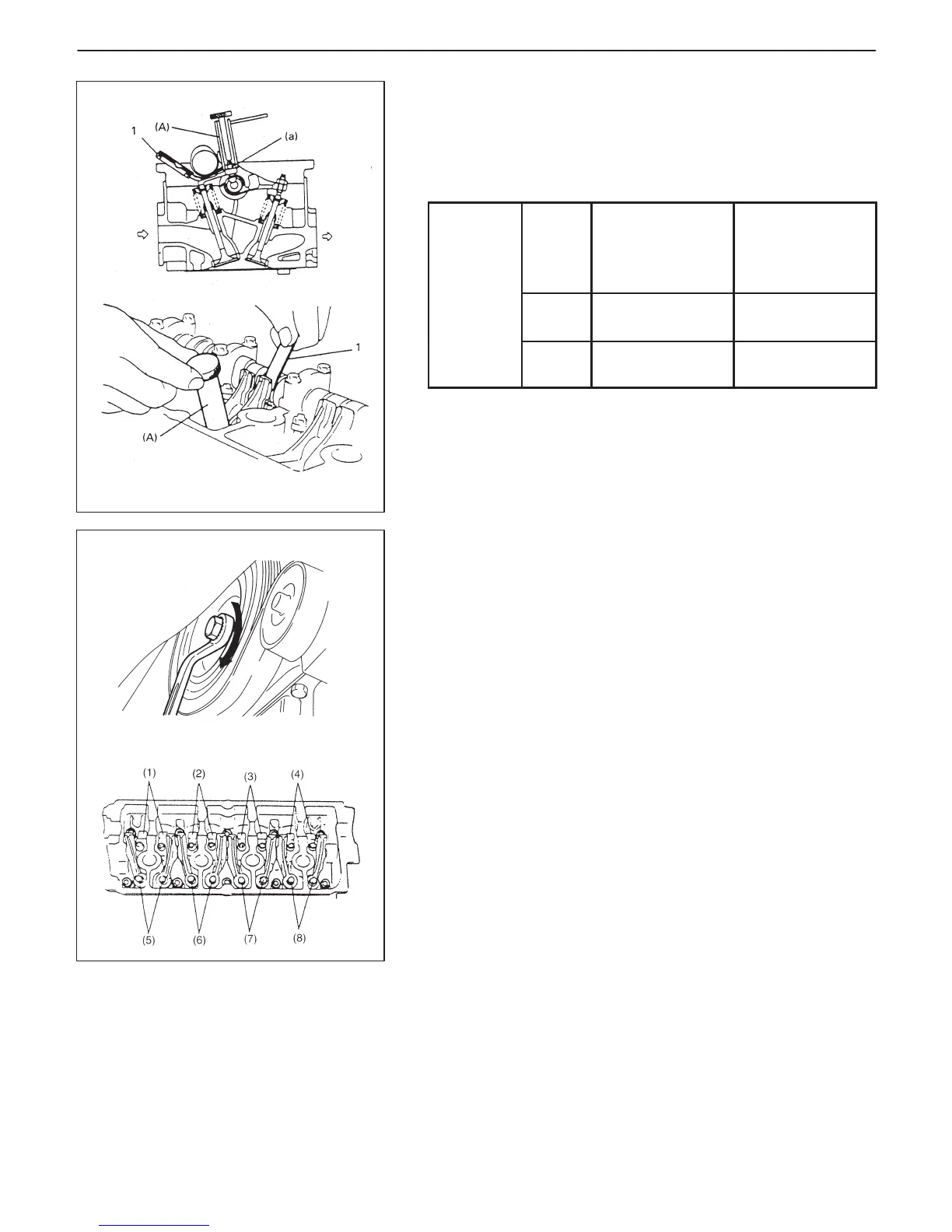

IN

EX

360_

IN

EX

6A1-10 ENGINE MECHANICAL (G13B, 1-CAM 16-VALVES ENGINE)

6) If valve lash is out of specification, adjust it to specification by

turning adjusting screw after loosening lock nut.

After adjustment, tighten lock nut to specified torque while hold-

ing adjusting screw stationary, and then make sure again that

valve lash is within specification.

Valve

clearance

When cold

(Coolant tempera-

ture is 15 – 25_C

or 59 – 77_F)

When hot

(Coolant tempera-

ture is 60 – 68_C

or 140 – 154_F)

specifica-

tion

Intake

0.13 – 0.17 mm

(0.005 – 0.007 in.)

0.18 – 0.22 mm

(0.007 – 0.009 in.)

Exhaust

0.23 – 0.27 mm

(0.009 – 0.011 in.)

0.28 – 0.32 mm

(0.011 – 0.013 in.)

Special Tool

(A): 09917-18211

Tightening Torque

(a): 12 N

.

m (1.2 kg-m, 9.0 lb-ft)

7) After checking and adjusting valve lashes at valves (1), (2), (5)

and (7), (or (3), (4), (6) and (8)) rotate crankshaft exactly one full

turn (360_) and check the same at valves (3), (4), (6) and (8) (or

(1), (2), (5) and (7)). Adjust them as necessary.

8) After checking and adjusting all valves, reverse removal proce-

dure for installation.

Loading...

Loading...