IGNITION SYSTEM 6F-3

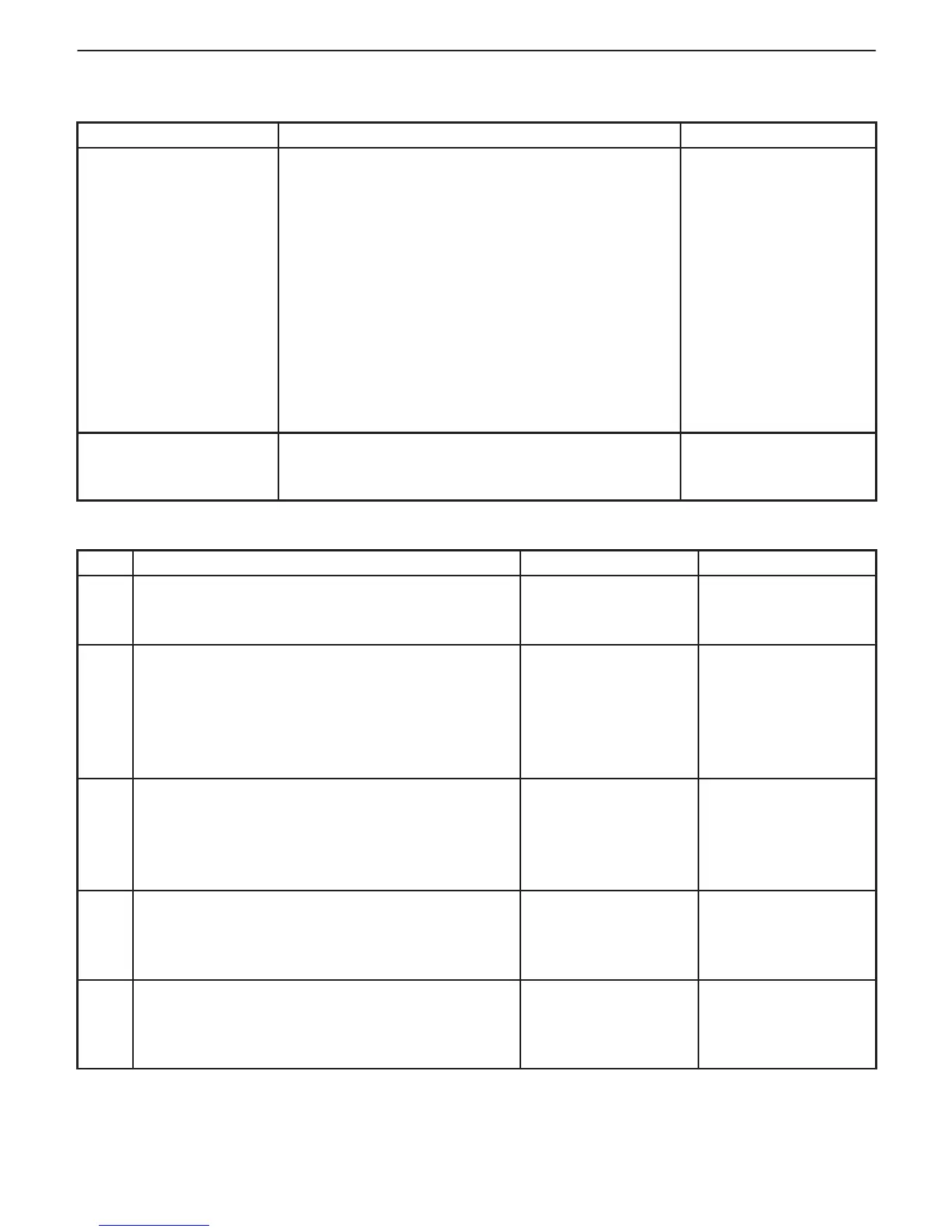

DIAGNOSIS

Condition Possible Cause Correction

Engine cranks, but will

not start or hard to start

D Blown fuse for ignition coil

D Loose connection or disconnection of lead wire or

high-tension cord(s)

D Faulty high-tension cord(s)

D Faulty spark plug(s)

D Cracked rotor or cap

D Maladjusted signal rotor air gap

D Faulty ignition coil

D Faulty noise suppressor

D Faulty CMP sensor

D Faulty igniter

D Faulty ECM (or PCM)

D Maladjusted ignition timing

Replace

Connect securely

Replace

Adjust, clean or replace

Replace

Adjust

Replace

Replace

Replace

Replace

Replace

Adjust

Poor fuel economy or

engine performance

D Incorrect ignition timing

D Faulty spark plug(s) or high-tension cord(s)

D Faulty ECM (or PCM)

Adjust

Adjust, clean or replace

Replace

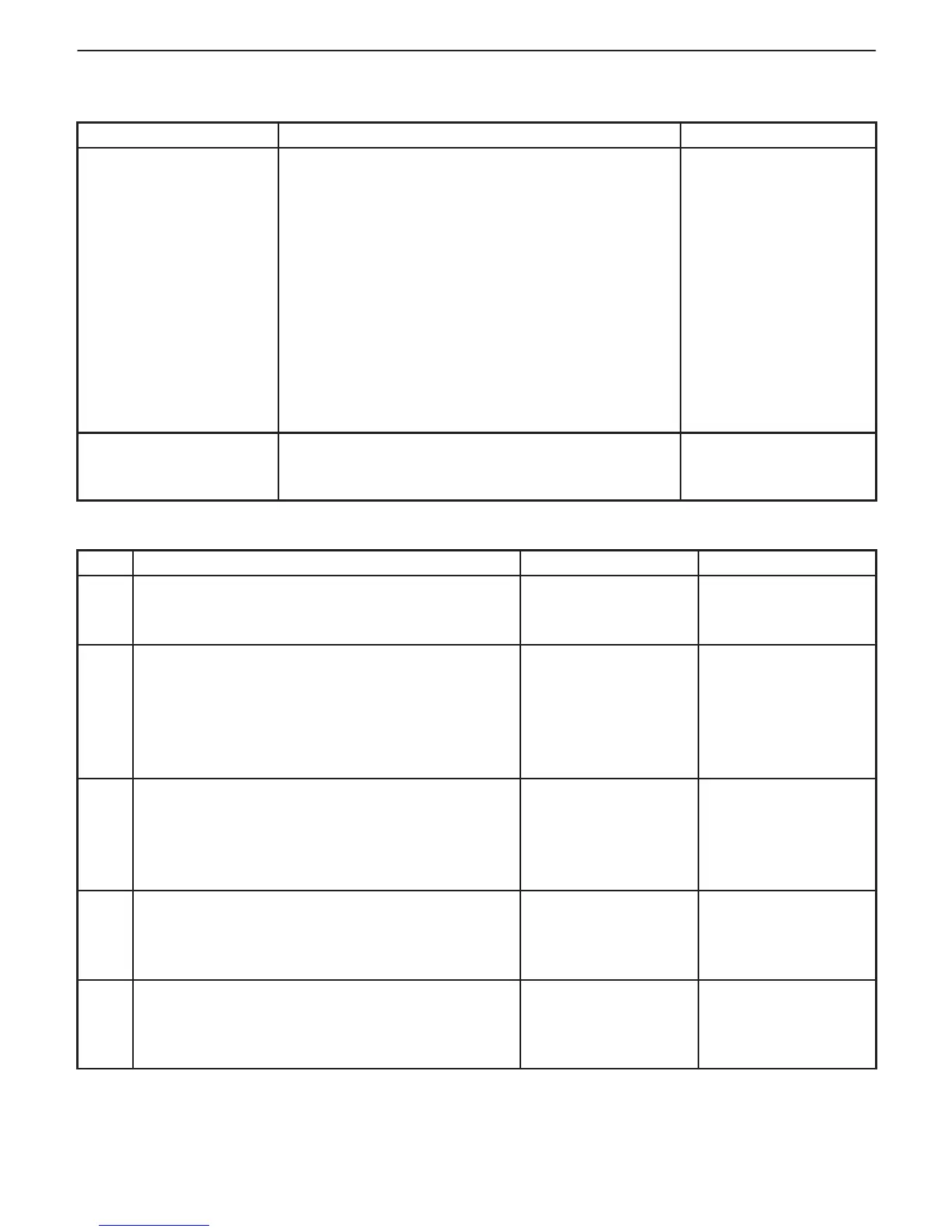

DIAGNOSTIC FLOW TABLE

STEP ACTION YES NO

1 Was “Engine Diagnostic Flow Table” in SECTION 6

performed?

Go to Step 2. Go to “Engine

Diagnostic Flow

Table” in SECTION 6.

2 Ignition Spark Test

1) Check all spark plug for condition and type,

referring to “Spark Plugs” in this section.

2) If OK, perform ignition spark test, referring to

“Ignition Spark Check” in this section.

Is spark emitted from all spark plugs?

Go to Step 11 on the

next page.

Go to Step 3.

3 Diagnostic Trouble Code (DTC) Check

1) Check DTC stored in ECM (or PCM), referring to

“Diagnostic Trouble Code (DTC) Check” in

SECTION 6.

Is DTC stored?

Go to applicable flow

table corresponding to

that code No. in

SECTION 6.

Go to Step 4.

4 Electrical Connection and Noise Suppressor Check

1) Check ignition coil for electrical connection and

noise suppressor for conductivity.

Are they good condition?

Go to Step 5. Repair or replace.

5 High-tension Cord Check

1) Check high-tension cord for resistance, referring

to “High-tension Cords” in this section.

Is check result satisfactory?

Go to Step 6. Replace high-tension

cord(s).

Loading...

Loading...