ENGINE GENERAL INFORMATION AND DIAGNOSIS (TBI FOR G10) 6-45

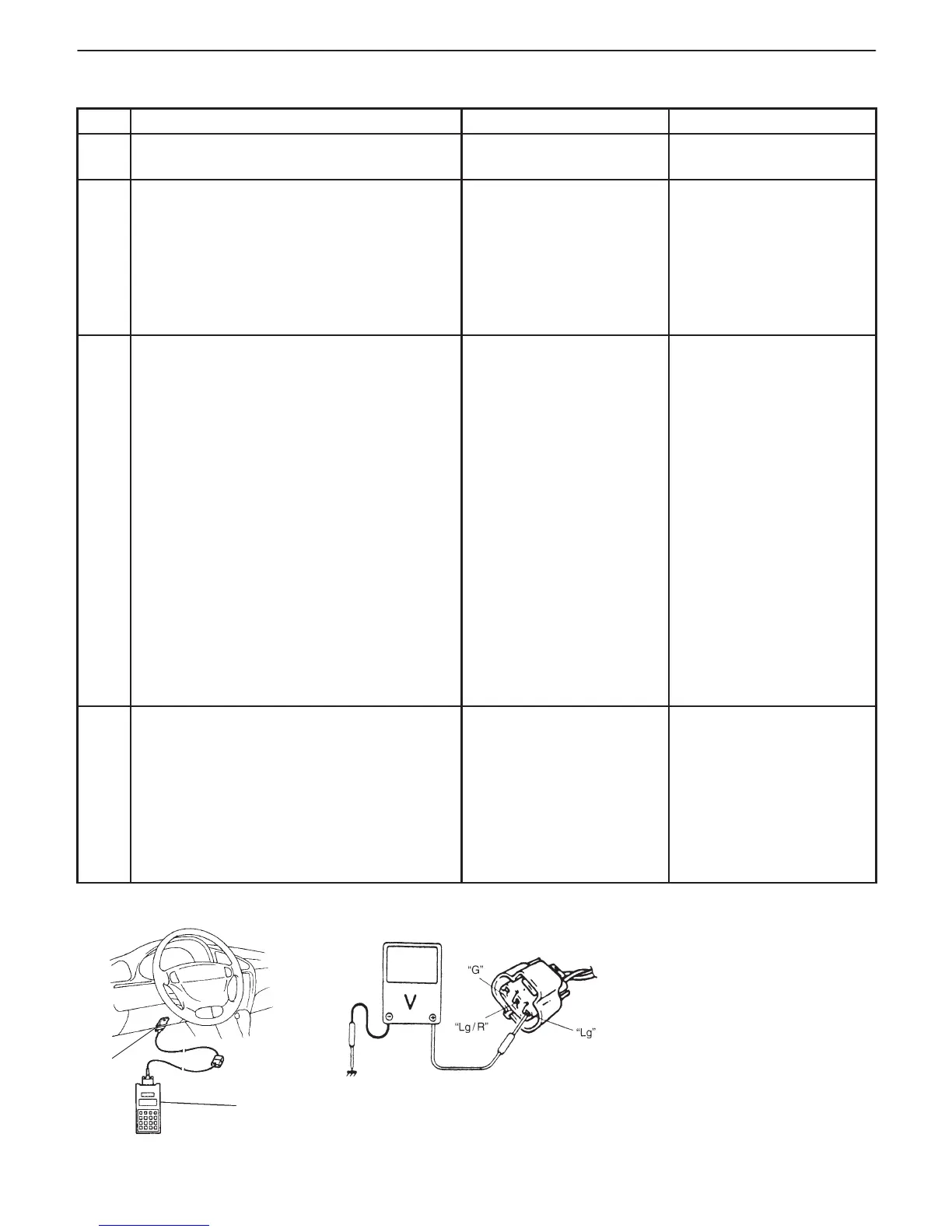

Fig. 1 for Step 2 Fig. 2 for Step 3

Scan tool

DLC

INSPECTION

STEP ACTION YES NO

1 Was “ENGINE DIAG. FLOW TABLE”

performed?

Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Check MAP Sensor and Its Circuit.

1) Connect scan tool to DLC with ignition

switch OFF.

2) Turn ignition switch ON.

3) Check intake manifold pressure.

See Fig. 1.

Is it 130 kPa or more or 5 kPa or less?

Go to Step 3. Intermittent trouble.

Check for intermittent

referring to

“INTERMITTENT AND

POOR CONNECTION” in

Section 0A.

3 Check Wire Harness.

1) Disconnect MAP sensor connector with

ignition switch OFF.

2) Check for proper connection of MAP

sensor at “Lg/R” and “G” wire

terminals.

3) If OK, then with ignition switch ON, check

voltage at each of “Lg” and “Lg/R” wire

terminals. See Fig. 2.

Is voltage about 4 – 6 V at each terminal?

Go to Step 4. “Lg” wire open or

shorted to ground circuit or

shorted to power circuit,

“Lg/R” wire open or

shorted to ground, poor

C01-5 connection or

C01-1 connection.

If wire and connection are

OK, confirm that MAP

sensor is normal and then

substitute a known-good

ECM (PCM) and recheck.

NOTE: When battery

voltage is applied to

“Lg” wire, it is possible

that MAP sensor is also

faulty.

4 Check MAP sensor according to “MAP

Sensor Individual Check” in Section 6E1.

Is it in good condition?

“Lg” wire shorted to

“Lg/R” wire, “G” wire

open, poor C01-9

connection.

If wire and connection are

OK, substitute a known-

good ECM (PCM) and

recheck.

Replace MAP sensor.

Loading...

Loading...