FY operation manual 48

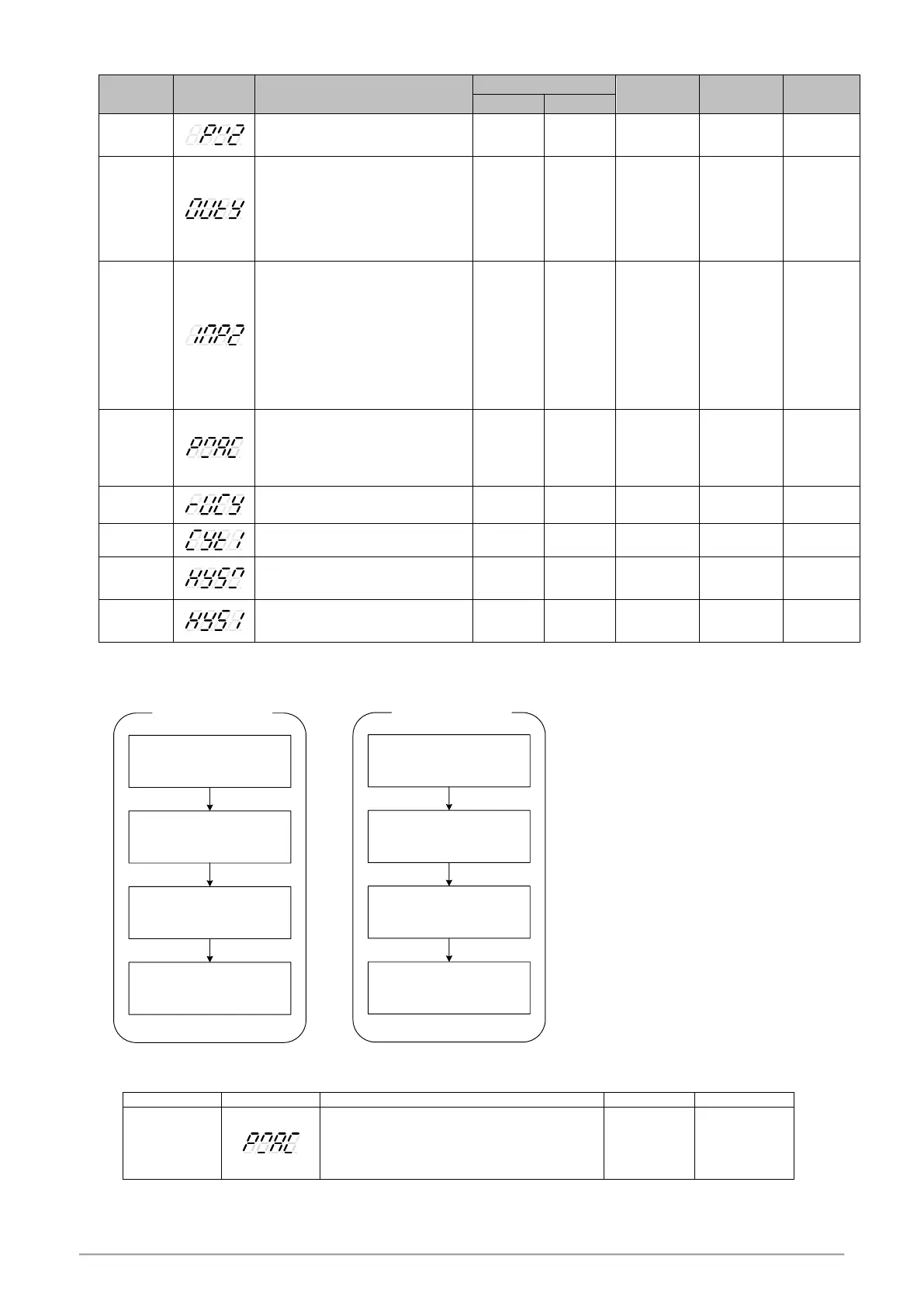

Parameter

Hardware drive selection

0 : single output control

1 : dual output control

2 : valve control with feedback

3 : valve control without feedback

selection

4 : single phase control

Sub input type selection

0 : none

1 : 10~50mV / 4~20mA / 1~5V /

2~10V

(only available in remote SV)

2 : 0~50mV / 0~20mA / 0~5V /

0~10V

(only available in remote SV)

3 : valve feedback

4 : CT input

Automatic valve position adjustment

0 : OFF stop automatic adjust

1 : ON start automatic adjust

2 : E_PB Valve position determined

by external button

Motor valve traveling time

Time unit

:

second

Motor valve action interval time.

Time unit : second

Motor valve action main adjustment

unit : percentage

Motor valve action sub adjustment

unit : percentage

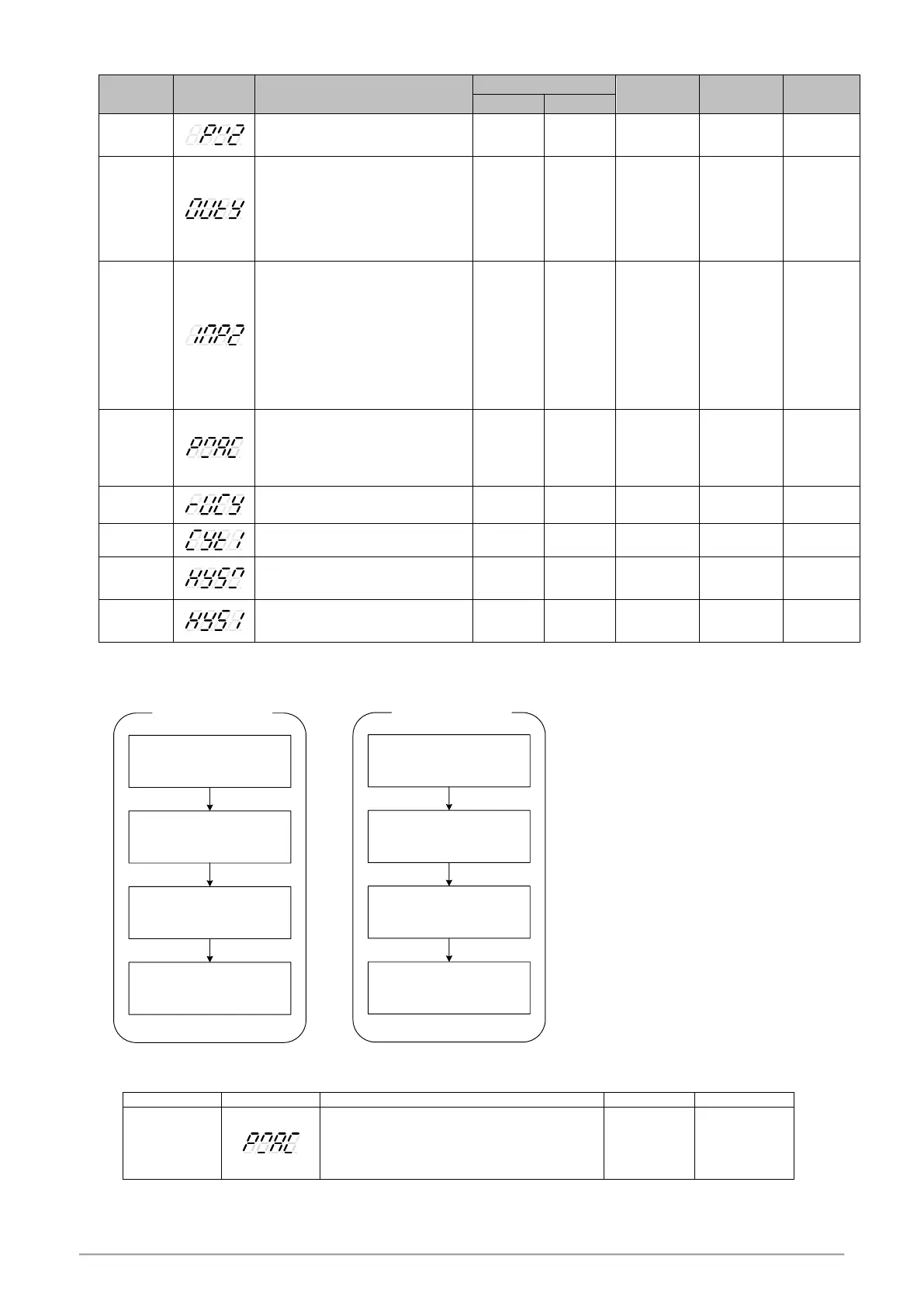

Motor valve Initial Setting

Set Motor valve traveling

time

( RUCY )

Set motor valve action

interval time

( CYT1 )

Set motor valve action

main hysteresis

( HYSM )

Set motor valve action

sub hysteresis

( HYS1 )

Without feedback

resistance

Executing automatic valve

position adjustment

( PMAC = ON )

Set motor valve action

interval time

( CYT1 )

Set motor valve action

main hysteresis

( HYSM )

Set motor valve action

sub hysteresis

( HYS1 )

With feedback

resistance

1. Executing automatic valve position adjustment

Automatic valve position adjustment

0 : OFF stop automatic adjust

1 : ON start automatic adjust

2 : E_PB Valve position determined

by external button

The motor valve low position(ANL2) and high position(ANH2) are calibrated and the travel time from completely open

to completely closed is set automatically

When the measurement has been complete the setting of the parameter will change to OFF.”PMER” will be display if any

of following errors occurs during execution.If an error occur check the wiring and other factors and execute automatic valve

Loading...

Loading...