17 / 52

Example:

After having run the welding tests, the result was that the usable life of the electrodes = 2000 welding

spots. Another fact that ensued was that the required current for new electrodes = 15 kA, whereas after

2000 welding spots the diameter increase of the electrodes requires a current of 19 kA.

Therefore calculate the change in percent as follows:

Consequently the following parameters are set in the "Stepper" menu:

%26100

15

1519

100% =×

=×

=

rentinitialcur

rentinitialcurendcurrent

Change

PARAMETER DESCRIPTION VALUE

STEPS INCREM Number of segments for stepper function 1

SPOTS 1 First segment spots number 2000

INCREMENT1 First segment increment percent 26%

The welding program should be adjusted for carrying out the first welding spot followed by the

adjustment that permits to obtain the required current with the starting electrode diameter: 15 kA.

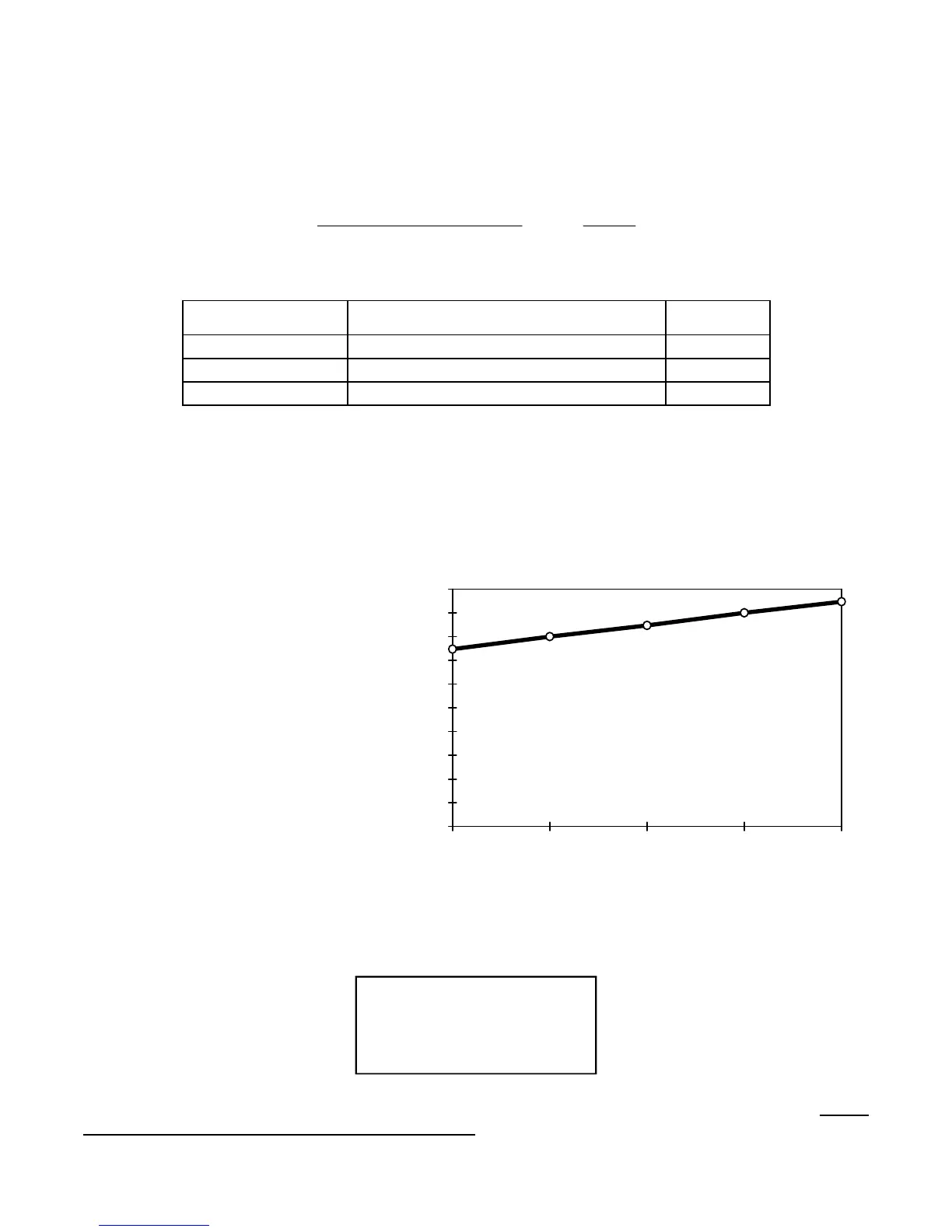

Now the welding process can begin. Current will vary conforming to the set increment rule. The graph

below shows its pattern.

INITIAL CURRENT = 15 kA

END CURRENT = 19 kA

INCREMENT PERCENT = 26 %

NUMBER OF WELDING SPOTS = 2000

CURRENT INCREMENT DURING PRODUCTION

0

2

4

6

8

10

12

14

16

18

20

0 500 1000 1500 2000

NUM BER OF WELDING SPOT S

WELDING CURRENT (k

Upon having completed all 2000 welding spots the TE500 stops the production cycle and displays the

following message:

22

------STOP------

MAX. N. of SPOTS

At this point the operator replaces the electrodes (or resets their original diameter) and clears

the spots counter to clear stepper calculations. The TE500 resets the initial work parameters

and begins a new increment phase.

Loading...

Loading...