51 / 52

FIRST INSERTION DELAY ADJUSTMENT

During the installation phase, the first insertion delay is to be adjusted. This adjustment allows the

optimizing of the welder's line consumption balance. Adjust by setting the control unit to maximum

power (CURRENT 1 = 99%) and carry out "loadless" welding spots, interrupting the secondary circuit

(e.g. by placing non-conducting material in between the electrodes). Adjust the "FIRST DELAY"

parameter (see the "INSTALLATION" paragraph) so that positive and negative line consumptions are

balanced. It is possible to use two different solutions for measuring the primary current:

Use an ammeter capable of measuring positive and negative maximum peak values (such as the

TECNA TE1600). In this manner the adjustment will be correct when the positive peak value will be

similar to the negative one. The value of the current consumed by the welder (when loadless) might be

too low for the instrument's minimum capacity. Solve this problem by running the cable, on which the

measurement is being taken, inside the current sensor several times. In this case the read value will be

multiplied by the same number of cable-run-through operations performed in the sensor.

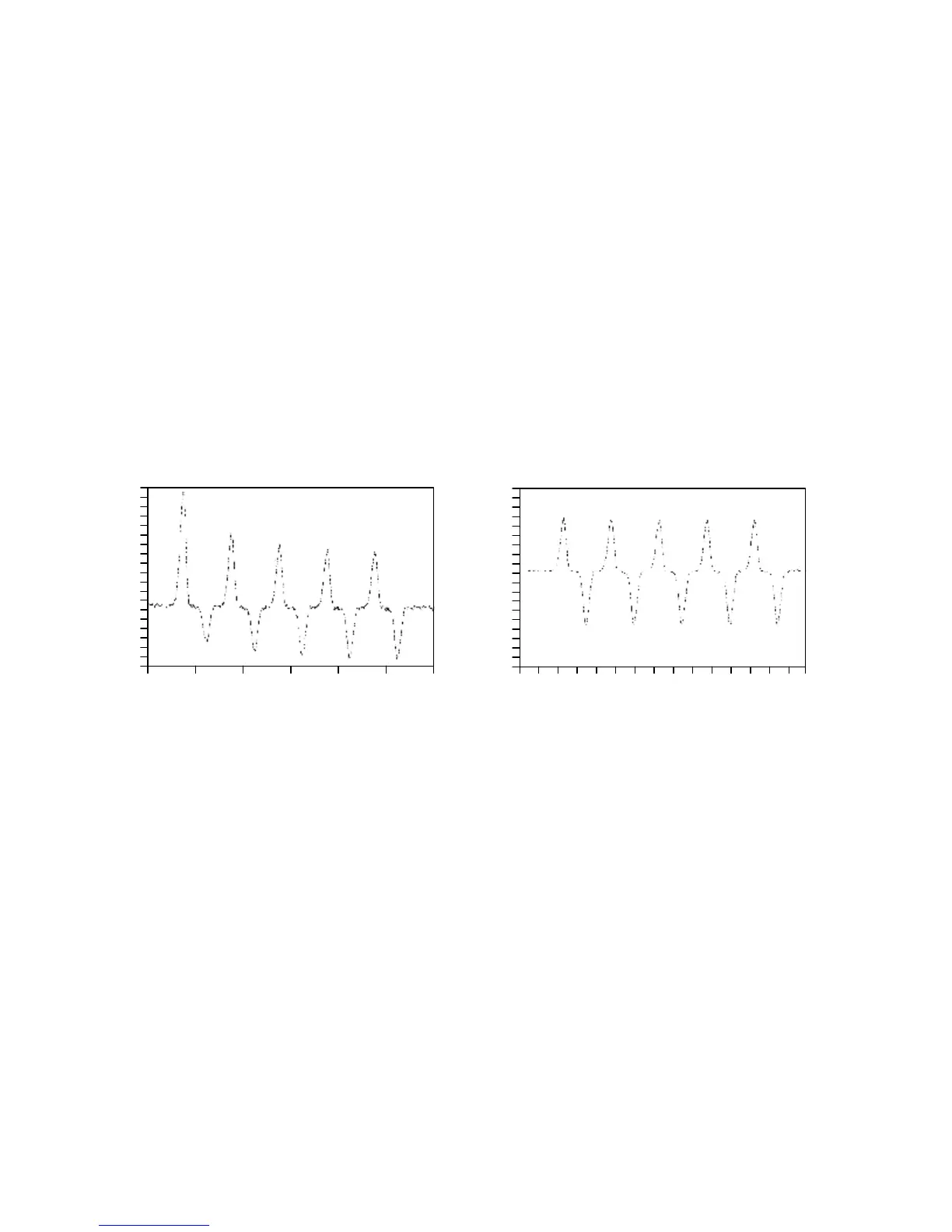

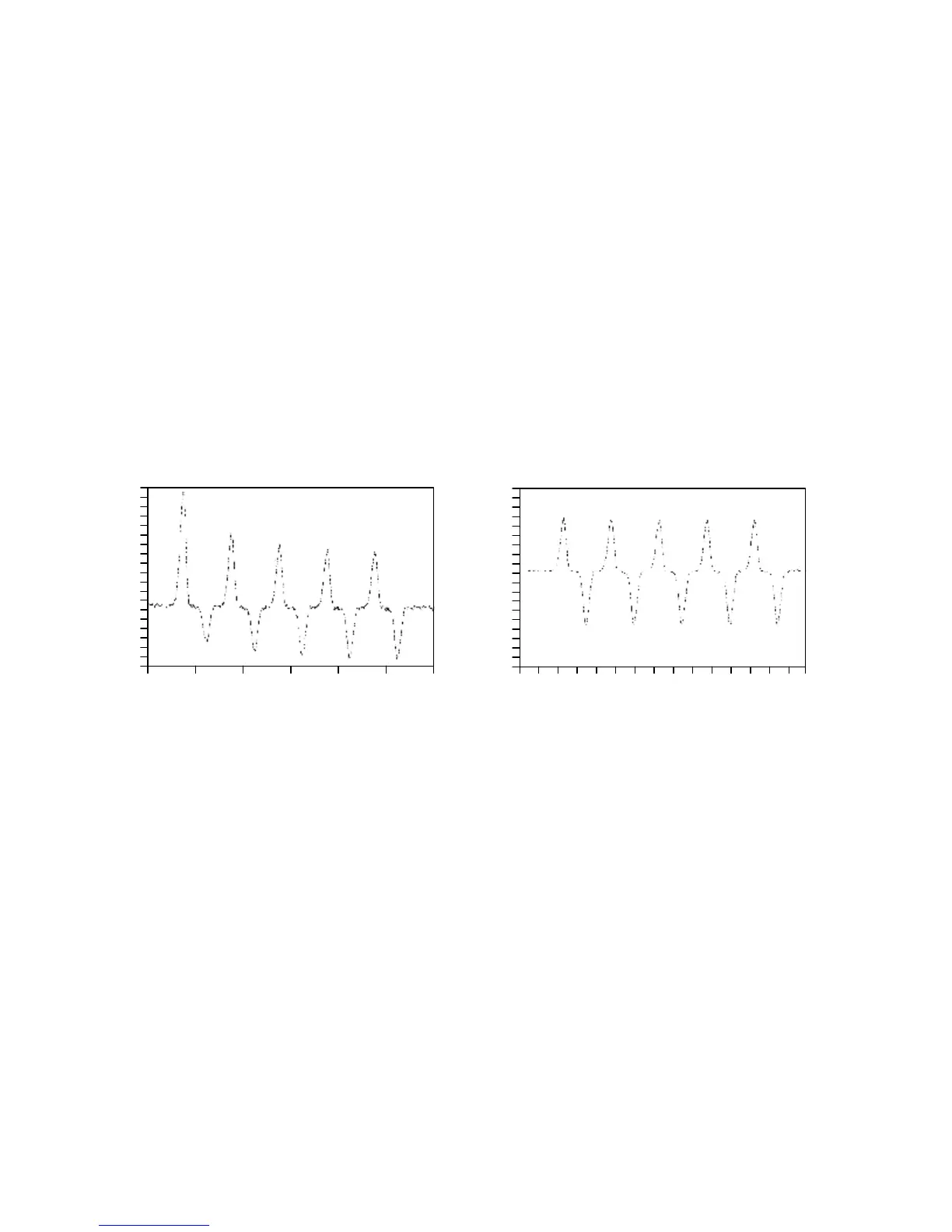

Use an ammeter that allows the displaying of the wave forms on a digital oscilloscope. In this case

perform the adjustment so that all the half waves of the primary current have the same amplitude. The

graphs below show the wave forms achieved both with an incorrect and a correct adjustment.

Unbalanced consumption Balanced consumption

Loading...

Loading...