26 / 52

For each start cycle signal a spot is carried out with the weld program associated with the current step.

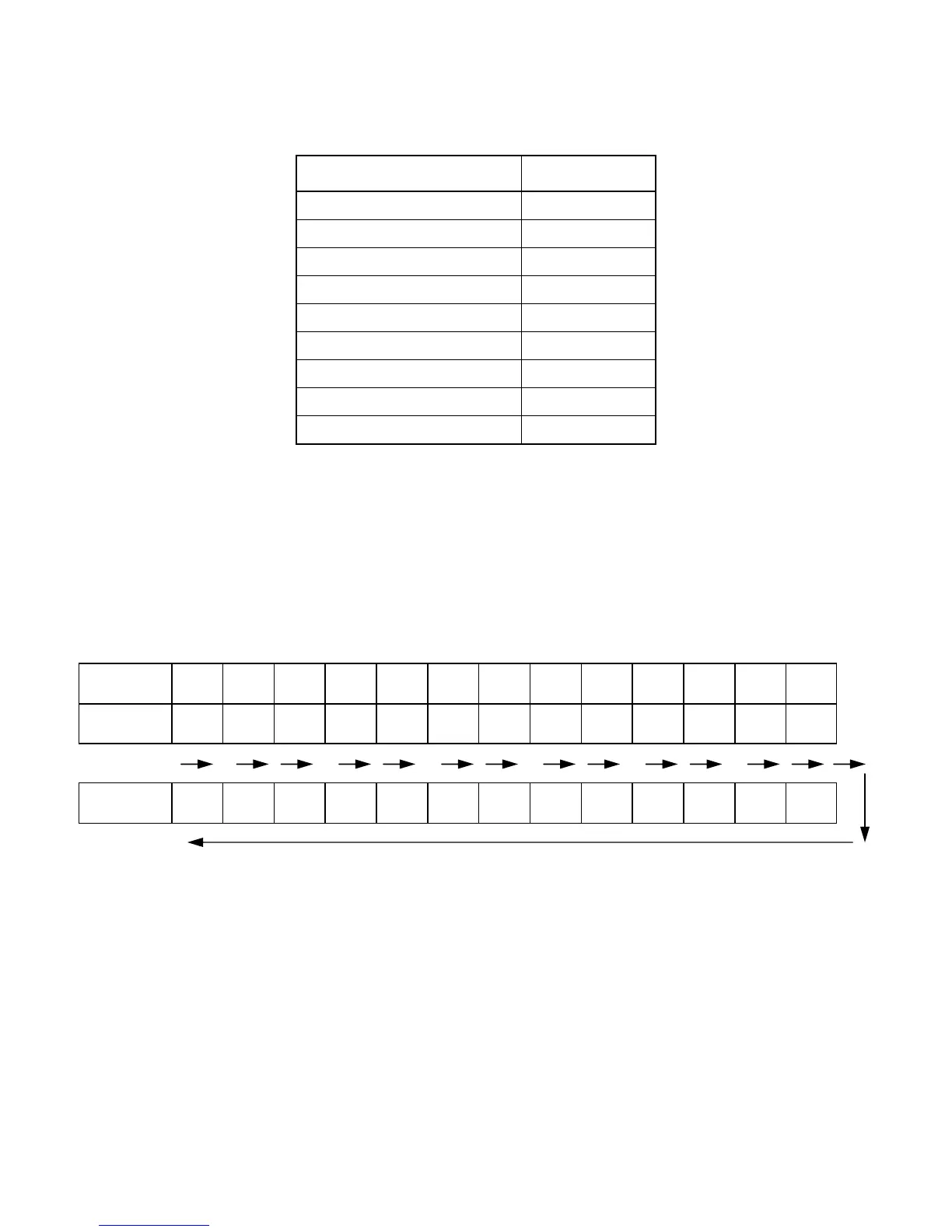

In this specific case, as shown in the chart below, the following welds are performed in sequence:

$ 4 welds with program 03

$ 2 welds with program 07

$ 6 welds with program 11

$ 1 weld with program 04

PARAMETER VALUE

NUMBER SEQUENCE 04

STEP 1 PRG. 03

STEP 1 WELDS 04

STEP 2 PRG. 07

STEP 2 WELDS 02

STEP 3 PRG. 11

STEP 3 WELDS 06

STEP 4 PRG. 04

STEP 4 WELDS 01

Let's take for example the sequence operation after having set the following values in the parameters.

PROGRAM SEQUENCE MENU

Usually this type of operation is applied to one manual welder where the operator always performs weld

spots in the same order but with different work parameters. By means of this system the operator does

not need to change the program manually which would cause his/her attention to be distracted from the

workpiece to be welded or does not have to change pedal or other start cycle device.

However the operator must pay utmost attention during the process not to perform fewer spots than

those programmed, overlapping spots or not in the same order.

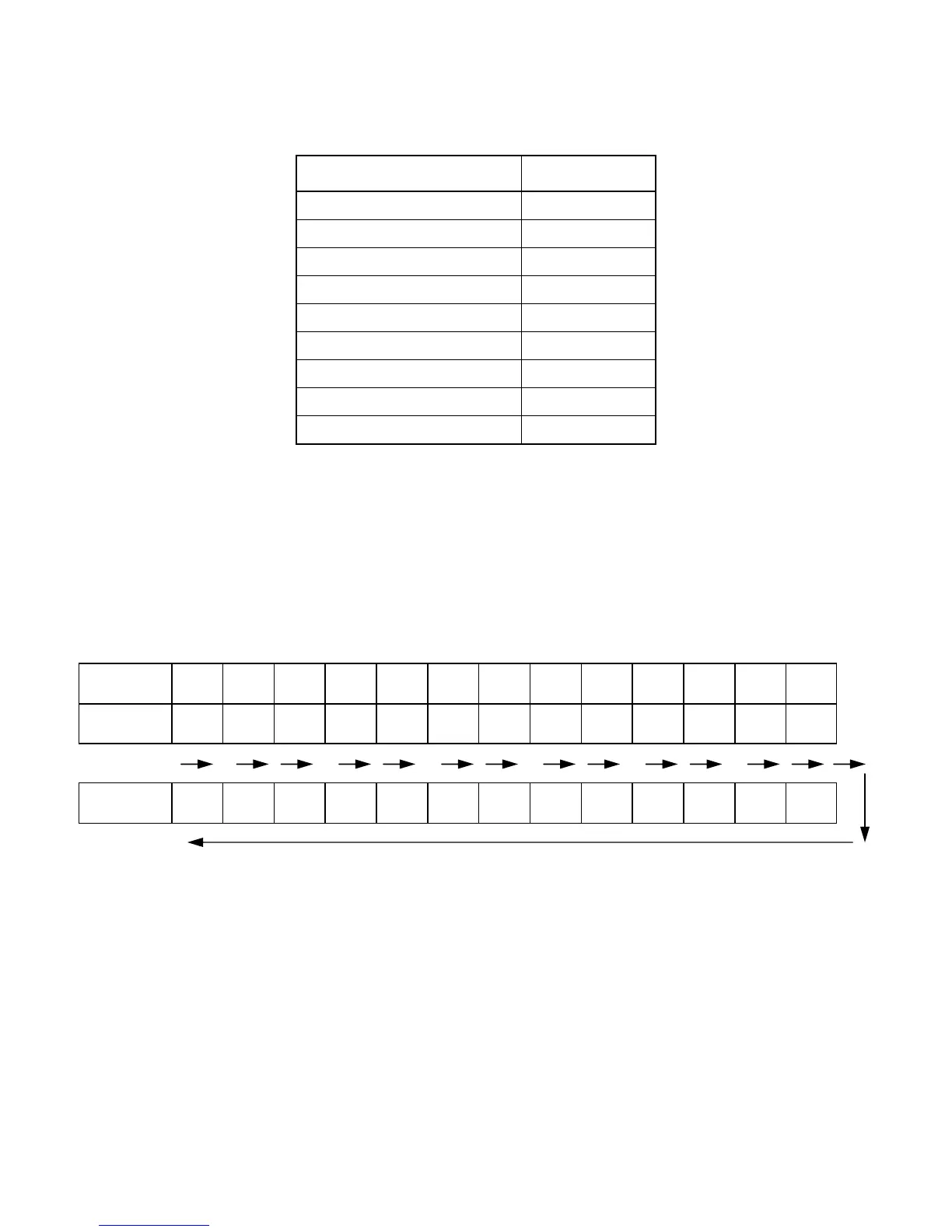

WELD 1 2 3 4 5 6 7 8 9 10 11 12 13

STEP 1 1 1 1 2 2 3 3 3 3 3 3 4

PROG 03 03 03 03 07 07 11 11 11 11 11 11 04

Loading...

Loading...