30 / 52

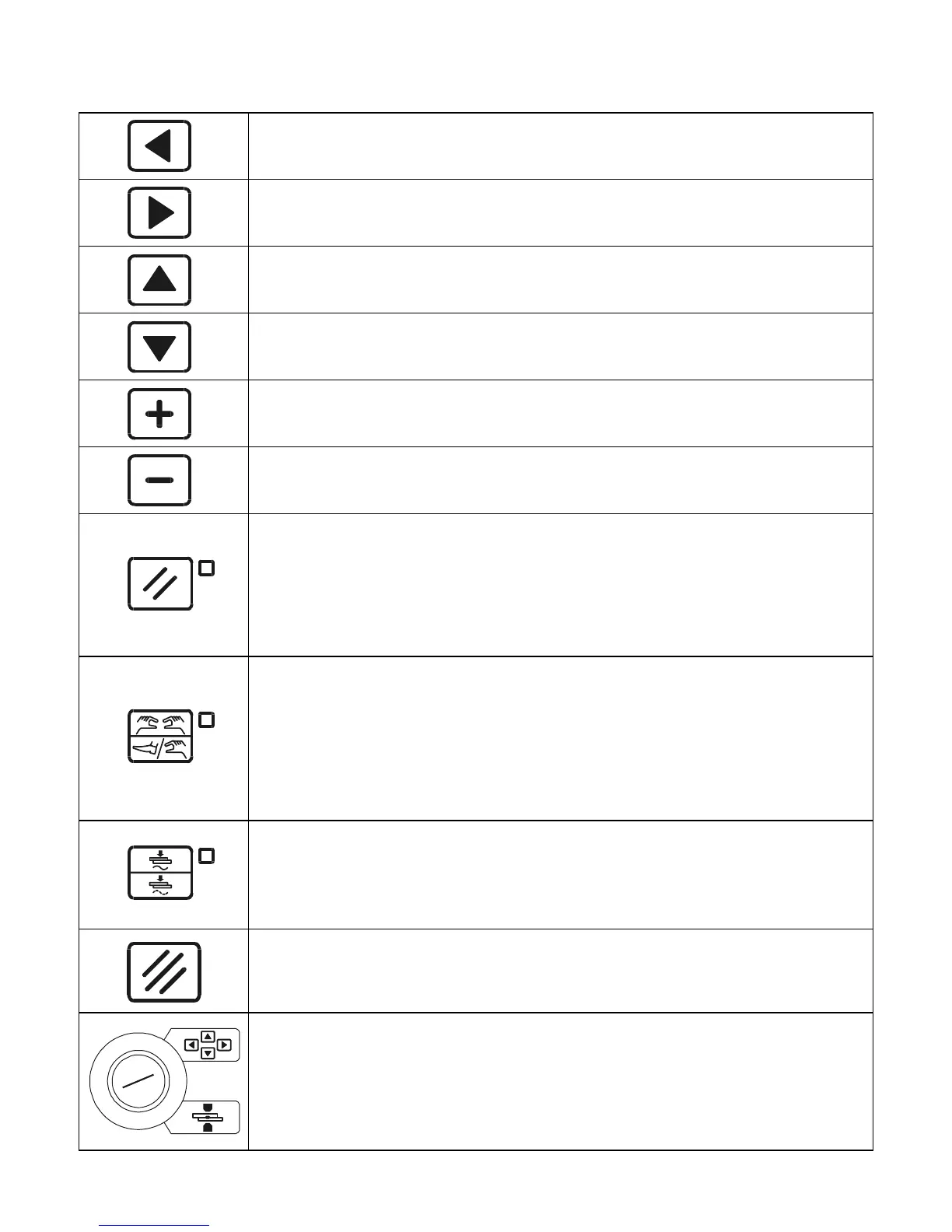

Left direction key used for exiting from the programming menu.

Right direction key used for accessing the programming menu.

Up direction key used for moving the cursor into the upper parameter.

Down direction key used for moving the cursor into the lower

parameter.

This key is used for increasing the value of a numeric parameter, or for

changing the status of a parameter.

This key is used for decreasing the value of a numeric parameter, or for

changing the status of a parameter.

RESTART key. It enables the commands and the control unit's outputs.

It must be pressed every time the control unit is powered. When this key

is pressed, all the devices connected to VAUX are powered such as for

example any double stroke valves. Before pressing the key it is

important to check that it will not cause injury/damage to people or

equipment.

Key for selecting the start cycle device: PEDAL or TWO-HAND

CONTROL. When the nearby LED is switched off, the start cycle

command is carried out by the PEDAL whereas if the LED is switched

on, the command is carried out by two-hand push buttons (TWO-HANDS

CONTROL). In order to work properly, the two push buttons must be

pressed at the same time or in sequence within a maximum time of 0.5

seconds conforming to the accident prevention regulations.

WELD-NO WELD Key. In WELD position (LED switched on) the control

unit runs the programmed welding cycle. In NO-WELD position (LED

switched off), the control unit runs the programmed cycle without welding

current circulation yet keeping all the time parameters unchanged.

CLEAR Key. It is used to clear the error conditions and for zeroing the

welds counter and during programming activities for zeroing the

parameters.

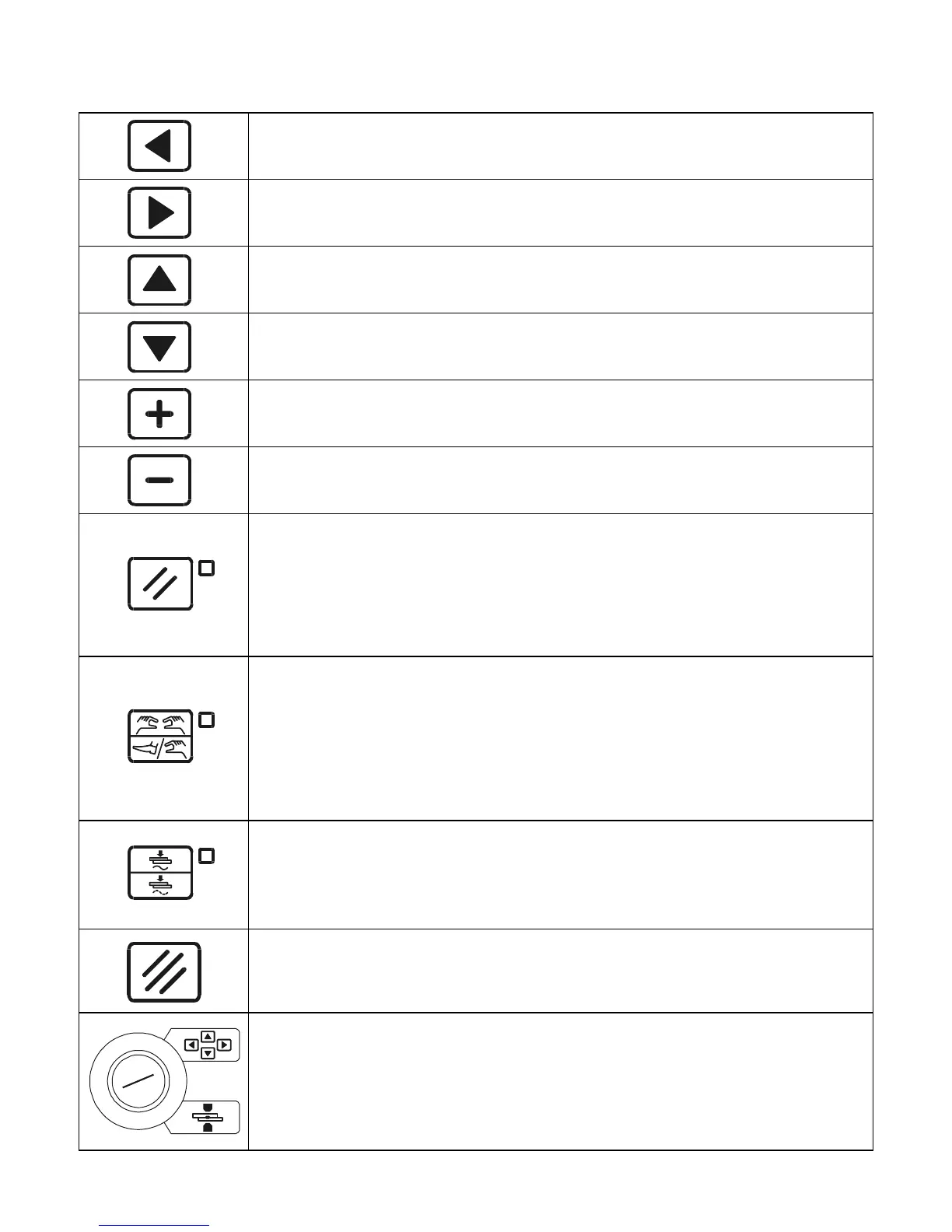

PROG-RUN Key selector. In PROG position (key turned to the 4-button

position) it enables the keyboard and allows the running of all the

foreseen programming operations. In RUN position it enables the spot

welder commands and allows the running of the work program only.

COMMANDS ON THE PANEL

Loading...

Loading...