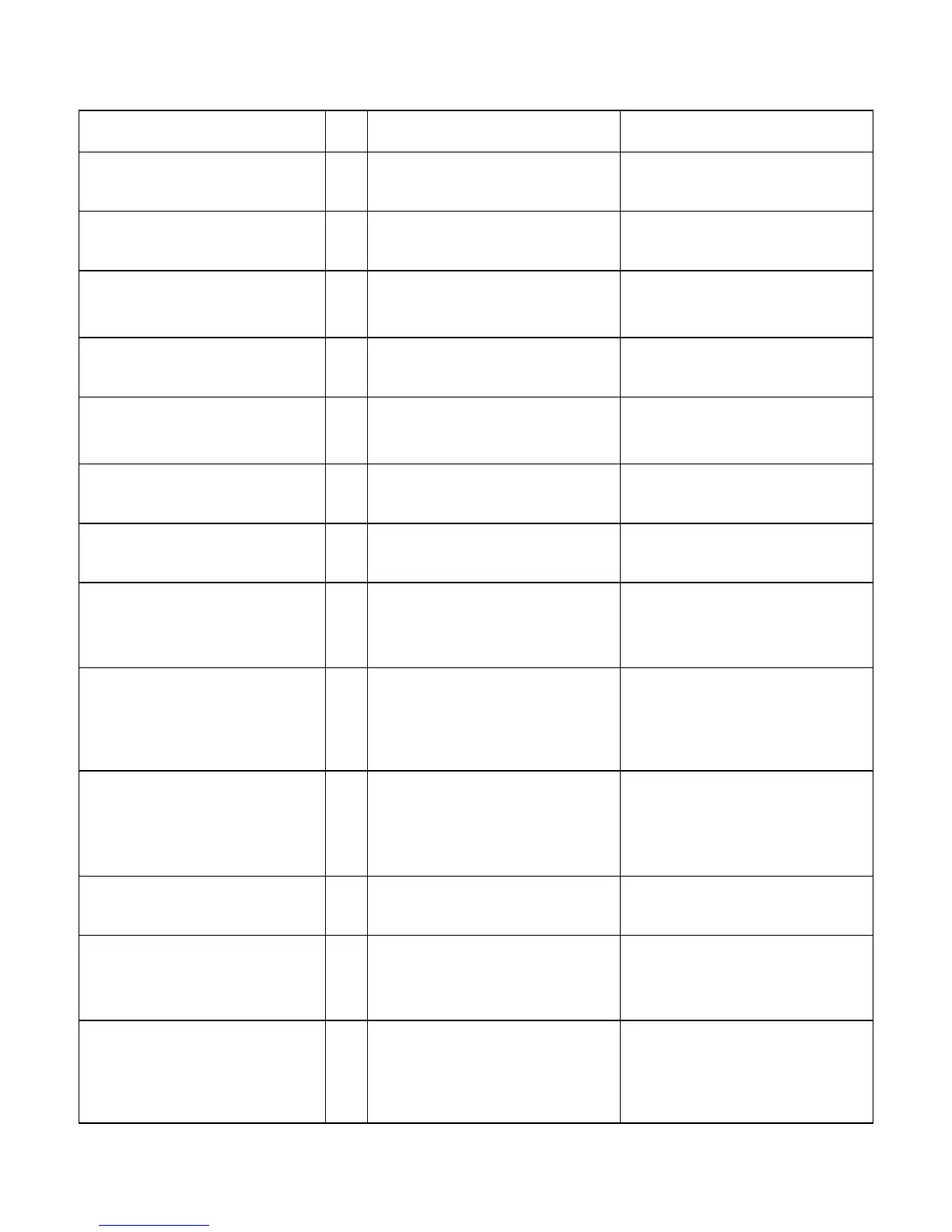

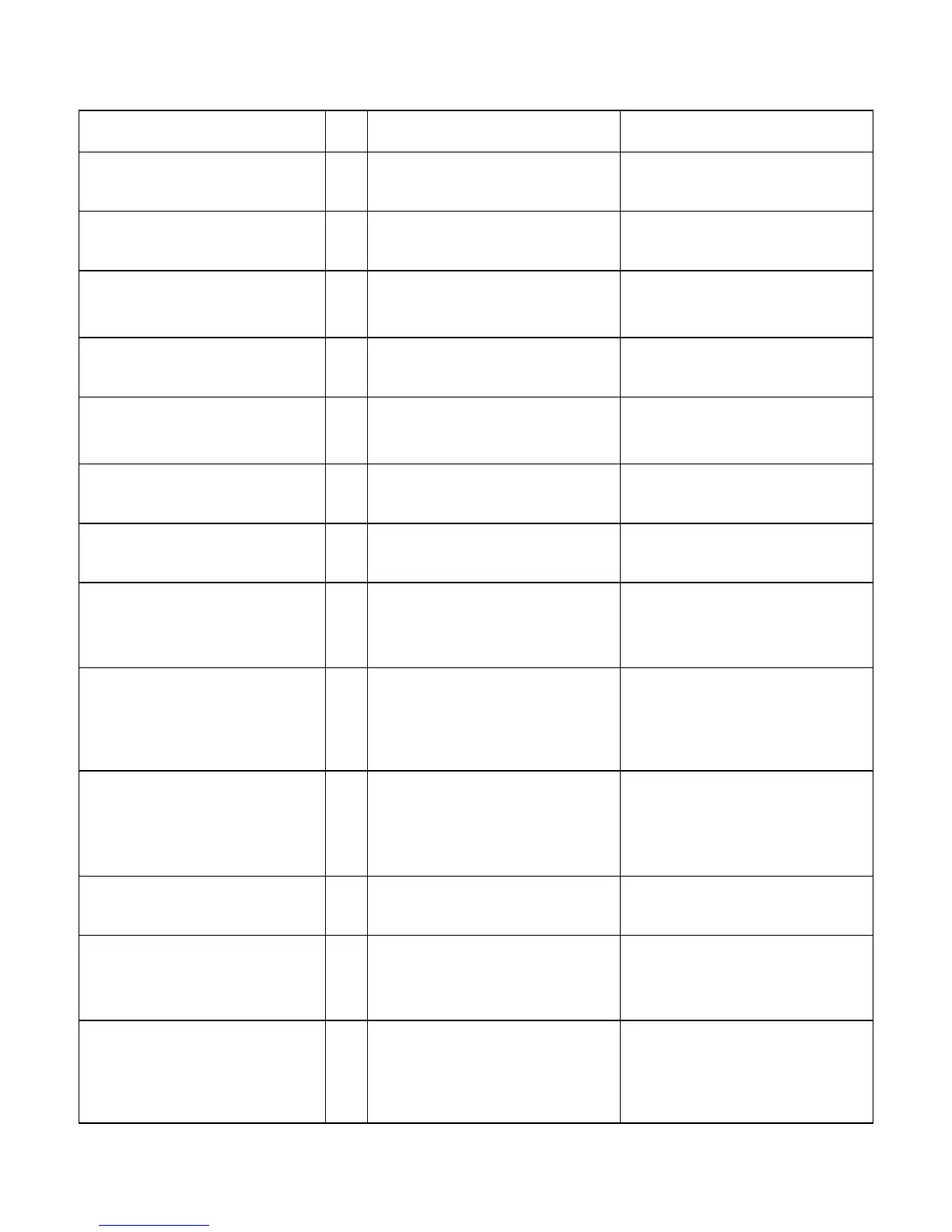

48 / 52

TE500 MESSAGES LIST Ver. 2.31

MESSAGE Nº CAUSE REMEDY

MAINS FREQUENCY

50 HZ

The control unit measured a mains

frequency of 50 Hz.

MAINS FREQUENCY

60 HZ

2

The control unit measured a mains

frequency of 60 Hz.

MAINS FREQUENCY

ERROR

3

The control unit was not able to

measure a steady mains

frequency.

Try to turn on the control unit again

and ensure that power supply is 24

VAC with 50/60 Hz frequency.

STORING OF

DEFAULT VALUES

4

The control unit is entering default

values in its program storage.

PRESS KEY [+]

TO ZERO DATA

5

The control unit's data zeroing

procedure has been activated.

Press key [+] to continue otherwise

press any other key or wait a few

seconds.

DATA ZEROING IN

PROGRESS

6

The data zeroing procedure of the

control unit is in progress.

SOFTWARE UPGRADE

IN PROGRESS

7

The upgrade procedure of the

control unit is in progress.

PRESS REARM KEY

[//] TO PROCEED

9

The control unit is waiting for the

rearm key to be pressed so as to

activate the welding control unit

functions.

Ensure that the activation of the

VAUX does not cause damage to

equipment and/or people, then

press the key.

ERROR - MAINS

SYNCHRONISM

10

A synchronism error has occurred

due to the temporary lack of the

reference signal of the power

supply line or due to line

interferences.

Clear the error by pressing any

key. If the error occurs frequently,

check the working efficiency of the

devices that cut the power supply

line and check for any interference.

TECNA TE500

VER. 2.31

WELDING CONTROL

UNIT

11

When the control unit is turned on

it displays the type of control unit

and the software version.

CALIBRATION IN

PROGRESS

12

The control unit is carrying out the

self-calibration welding procedure.

Complete the self-calibration

welding procedure.

CALIBRATION

CURRENT ERROR

13

Current measuring errors occurred

during the self-calibration

procedure.

Repeat the self-calibration

procedure. If the error occurs

again contact the customer

service.

CALIBRATION

OVERFLOW ERROR

14

During the self-calibration

procedure the control unit

measured a too-high current which

cannot be measured correctly.

The capacity of the built-in

ammeter is 36kA. Ensure that the

current supplied by the machine is

within this value. Contact the

customer service.

Loading...

Loading...