45 / 52

During this first weld the TE500 activates solenoid valve EV4 (that shifts the electrode from position "A"

to position "B"), waits a fixed time of 0.6 seconds and performs the programmed weld cycle. At the end

of the weld, solenoid valve EV4 is not deactivated and the electrode remains in position "B". The

succeeding welds will be performed starting from this position. When input D_STROKE is activated,

solenoid valve EV4 is kept activated and the electrode, in rest status, will be in position "B". Should the

operator need to open the electrodes during the process, deactivate the input to trigger the deactivation

of solenoid valve EV4.

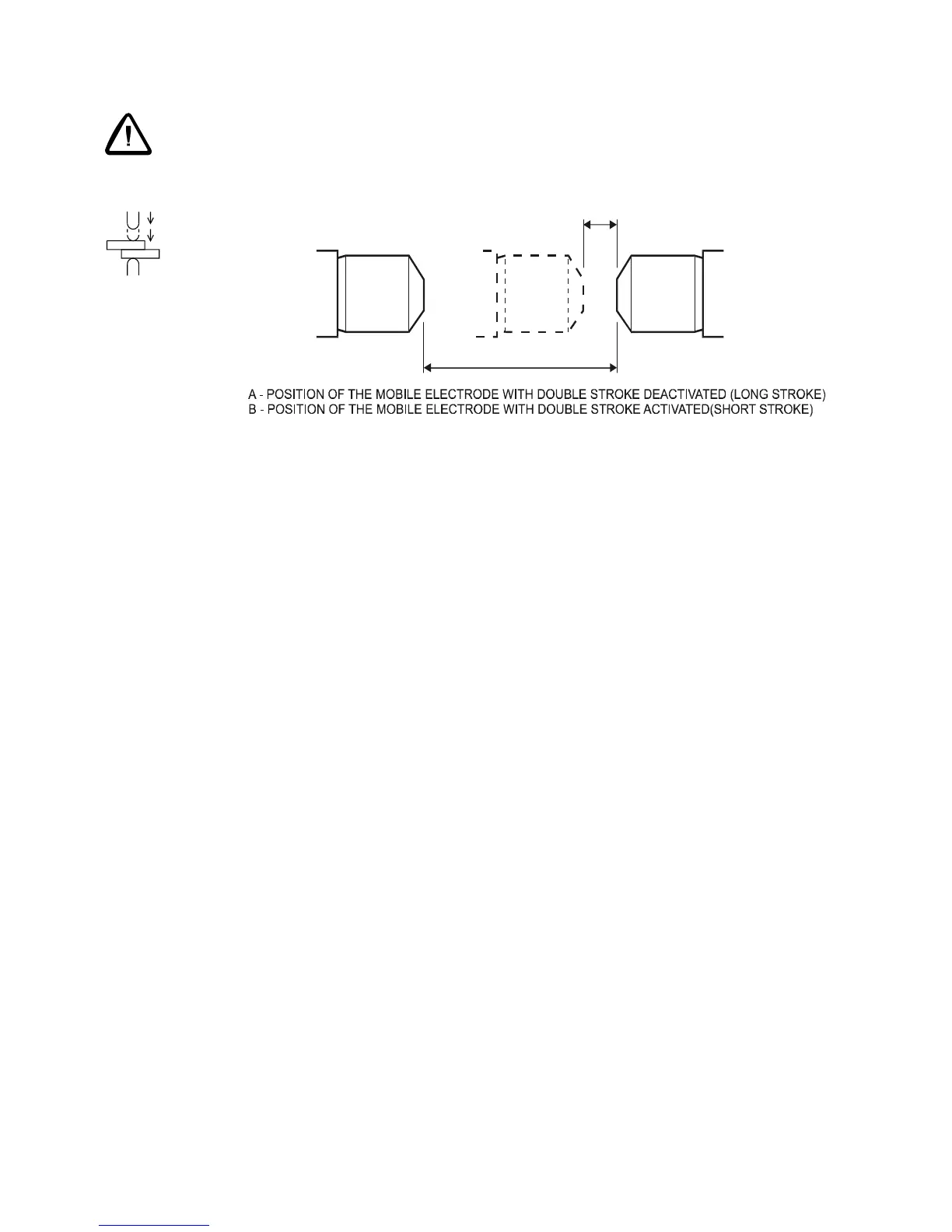

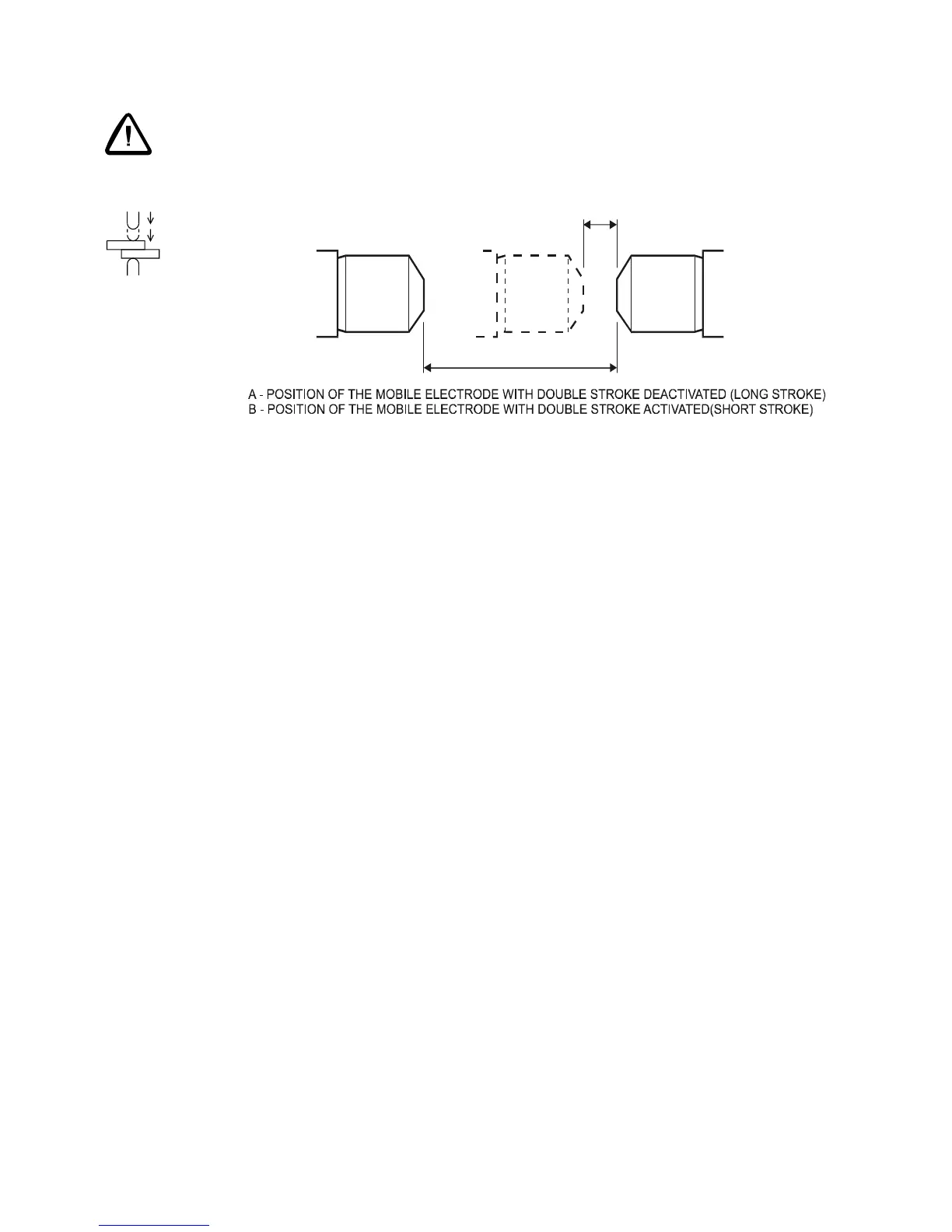

The output of the control unit called SV4 controls the double stroke solenoid valve.

When the machine is powered, it is always disabled even if the D_STROKE input is

active and the electrode is in position "A". The control unit sets it to position "B" when

the first weld is performed as shown in the figure below.

WORK STROKE (SHORT)

TOTAL STROKE (LONG)

AB

DOUBLE STROKE FUNCTION

Loading...

Loading...