8 / 52

There are few special conditions:

• If OFF TIME is set to (0), the welding control unit will work in single cycle.

• If OFF TIME is set to (99), the welding control unit will carry out the min. current compensation with a

value lower than 2.0 kA (see paragraph "COMPENSATION OF THE SECONDARY CURRENT")

• By setting the PRE-WELD parameter to zero, the pre-weld is not carried out.

• By setting the POST-WELD parameter to zero, the post-weld is not carried out.

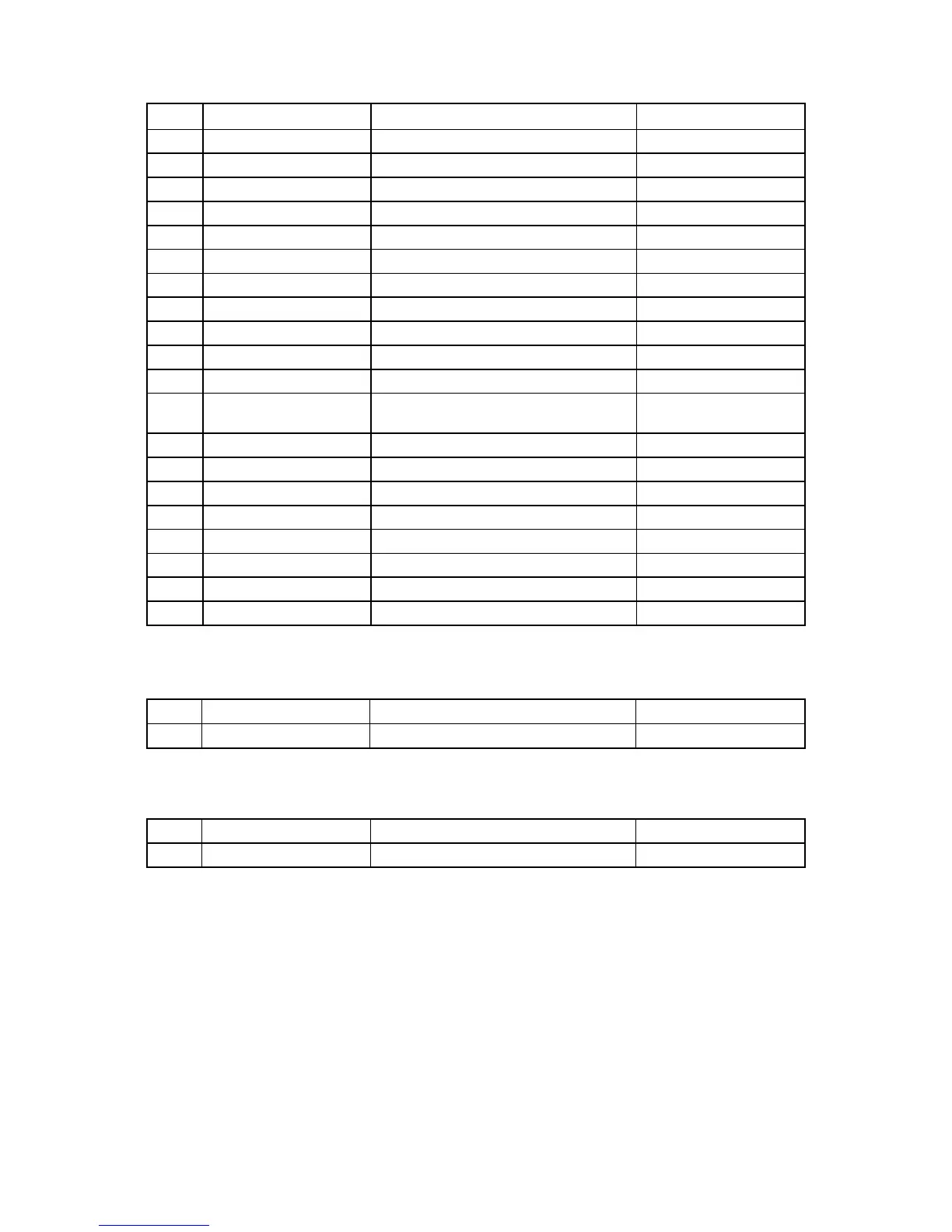

PARAMETER DESCRIPTION VALUE RANGE

WORK MODE WORK MODE IK - PW%-FIX

CONTROL MODE CONTROL MODE NO - CURR - DEG

1 SQUEEZE 1 1s1 SQUEEZE TIME 01 - 99 cycles

2 SQUEEZE SQUEEZE TIME 00 - 99 cycles

3 PRESSURE WELDING PRESSURE 00 - 99 cycles

4 FORGE DELAY FORGING TIME 00 - 99 cycles

5 PRE-WELD PRE-WELD TIME 00.0 - 99.5 cycles

6 PRE-POWER PRE-WELD CURRENT 05 - 99%

7 COLD I COLD 1 TIME 00 - 50 cycles

8 SLOPE UP SLOPE UP TIME 00 - 25 cycles

9 WELD 1 WELDING TIME 00.5 - 99.5 cycles

10

POWER 1

CURRENT 1

WELDING CURRENT

5 - 99%

1.0 - 90.0 kA

11 COLD 2 COLD 2 TIME 01 - 50 cycles

12 N. IMPULSE NUMBER OF IMPULSES 00 - 09

13 SLOPE DOWN SLOPE DOWN TIME 00 - 25 cycles

14 COLD 3 COLD 3 TIME 00 - 50 cycles

15 POST-WELD POST-WELD TIME 00.0 - 99.5 cycles

16 POST-POWER POST-WELD CURRENT 05 - 99%

17 HOLD TIME HOLD TIME 01 - 99 cycles

18 OFF TIME DWELL TIME 00 - 99 cycles

19 CURR MIN MIN LIMIT IN CURRENT 1.0 - 90.0 kA

20 CURR MAX. MAX. LIMIT IN CURRENT 1.0 - 90.0 kA

21 ANGLE MIN MIN LIMIT IN DEGREES 001° - 180°

22 ANGLE MAX. MAX. LIMIT IN DEGREES 001° - 180°

WORK PROGRAM PARAMETERS TABLE

If CONTROL MODE is activated it will be possible to have additional parameters, namely:

if the CONTROL MODE parameter is set to CURR, otherwise

if the parameter is set to DEG.

Loading...

Loading...