N3 Drive Operations Manual

Inverter Wiring; Input Power Wiring 12

8.3 Motor Cable Length

The length of the cables between the motor and inverter can cause a significant phase to phase voltage

reduction at the motor due to the voltage drop across the cables. To calculate this reduction, apply the following

formula:

Phase-to-phase voltage drop (V) = 3 ×resistance of wire (Ω/km) × length of line m) × current×10

-3

.

(km=3280 x feet) (m=3.28 x feet )

8.4 Cable Length vs Carrier Frequency

The allowable setting of the PWM carrier frequency is also determined by motor cable length and on is specified

in the following table.

Table 8.2 Cable Length vs Carrier Frequency

Cable length between the

inverter and motor

ft / m

Recommended carrier

frequency allowed

Setting of parameter

A044

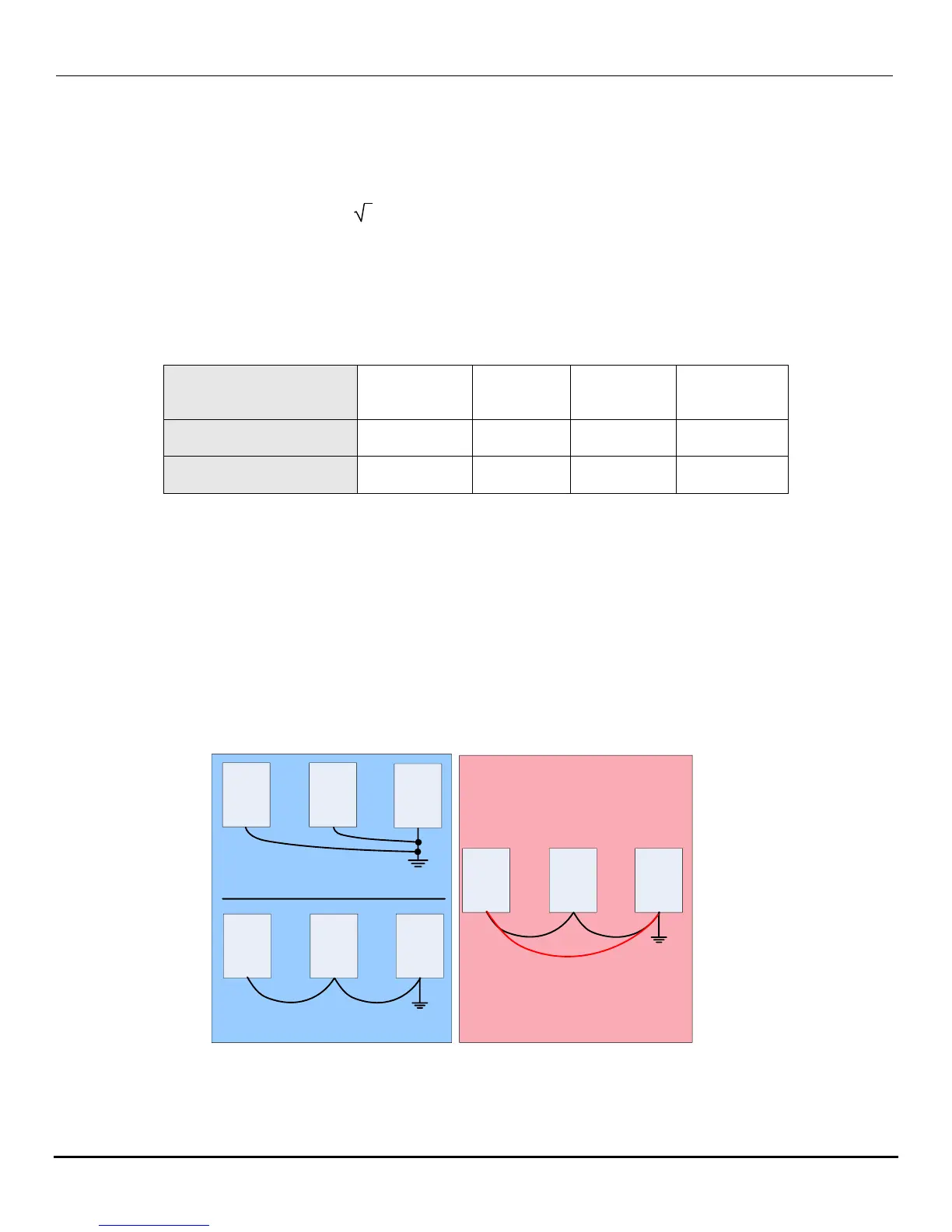

8.5 Inverter Grounding

The proper grounding scheme for one or more inverters is very important to ensure personnel safety as well as

equipment performance. The following will discuss the proper grounding procedures.

The grounding resistance for the 230V class; <100, the 460V class; <10.

The ground wire size (AWG) is per electrical code.

Do Not share a ground with any other equipment with high current loads such as welding machines, presses,

etc. Connect the inverter to its own dedicated ground.

Do Not make a loop when several inverters share a common ground point (See Fig. 8.5c).

N3 N3

N3

N3 N3 N3

a) Correct

b) Correct

N3 N3 N3

c) Incorrect

Loop

Fig. 8.5 Inverter Grounding

Loading...

Loading...