| Installaon Instrucons

1- WARNING

Transport

For informaon regarding the delivery of condensing units,

please refer to our sales terms and condions.

Installaon

- This condensing unit and all related equipment must be

installed by qualied sta.

- The installaon should be carried out in accordance with the

relevant refrigeraon and electrical standards which apply in

that country. Refrigeraon best pracce must be followed.

- TECUMSEH EUROPE S.A. shall not under any circumstance

be liable if the installaon and maintenance are not carried

out in accordance with the instrucons given in this manual.

2-TECHNICAL DATA

■ 2.1. Idencaon label for the SILENSYS range

See Appendix 1, page 30

■ 2.2. Safety devices

All units are supplied with an adjustable HP / LP pressure

switch, with a 16 A maximum current rang and a isolator

lockable in the ON or OFF posion as well as a thermal breaker

on the power circuit.

■ 2.3. Versions and opons available

HP / LP pressure switch with manual reset - fusible plug on the

receiver – liquid line sight glass on the receiver ed with a

fusible plug on twin fan models.

■ 2.4. Refrigeraon schemac

See Appendix 2 , page 30, 31

3- INSTALLATION

■ 3.1. Unpacking

Before unpacking the unit, check that the packaging has not

been damaged in any way and that the exterior is in good

condion.

■ 3.2. Handling

The packaged condensing unit can be lied by forkli or pallet

truck. The unit should therefore be kept in its packaging unl it

has been moved to the installaon site.

Once the packaging has been removed, Silensys units can be

moved or lied either by forkli or straps according to the

model. Units must not be dragged into posion.

■ 3.3. Locaon

Silensys® condensing units should not block or obstruct

thoroughfares, doors, shuers or the movement of personnel.

The surface supporng the condensing unit must be level and

capable of bearing the combined weight of the unit + support.

See table in Appendix 3, page 32 to 33 for condensing unit

weights.

Ensure there is sucient distance between the condensing

unit and objects in the surrounding area to ensure good air

circulaon.

See Appendix 3, pages 32 to 33

Silensys condensing units must be installed in well-venlated

but not windy locaons. Ensure there is good air circulaon

to the condenser. There must be no obstacles in front or to

the side of the unit which would cause air recirculaon to the

condenser. This will avoid among others an abnormally high

condensaon temperature. The unit must be set up in a level

posion and installed at an altude not exceeding 2000 m.

■ 3.4. Noise levels

Silensys condensing units have been designed to operate

extremely quietly.

Precauons must be taken during installaon to avoid

generang addional noise and vibraons:

- Units must be securely mounted on a stable, rigid base,

- Connecng pipework must be suciently exible to ensure

vibraon is not transmied to the rest of the installaon.

We somemes recommend isolang material be inserted

between the unit feet and the base or between the wall

mounng brackets and the wall. This can be either an isolang

pad or an- vibraon mounts (not supplied) conforming to

the manufacturer’s recommendaons for their selecon and

installaon. The selecon of any an-vibraon products and

their potenal for absorbing vibraon is not the responsibility

of Tecumseh Europe.

■ 3.5. Mounng (1 or 2 opons according to

model)

The unit must be installed and axed on a level plane.

Ensure the unit is securely xed to the type of oor or wall

surface upon which it is mounted using the appropriated

xings (not supplied).

- Floor mounng

See Appendix 3, pages 32 to 33

Do not use wooden beams as a base onto which the product

is xed. Create a concrete base strong enough to support the

load and vibraon. Use xing bolts which are of an appropriate

length and are capable of securing the product correctly.

Use the mounng kit supplied with the condensing unit.

- Wall mounng (single fan models only)

See Appendix 3, pages 32 to 33

Use the mounng kit supplied with the condensing unit.

Secure the product appropriately.

■ 3.6. Access to connecons

See Appendix 4, page 34

■ 3.7. Refrigeraon connecons

To ensure the quality of our products, the condensing unit has

been dehydrated and charged with nitrogen.

On models ed with sucon tube diameter 1 1/8 or 1 3/8 the

sucon line from the valve to the end of the tube is not under

nitrogen (the sucon line is plugged and the valve closed).

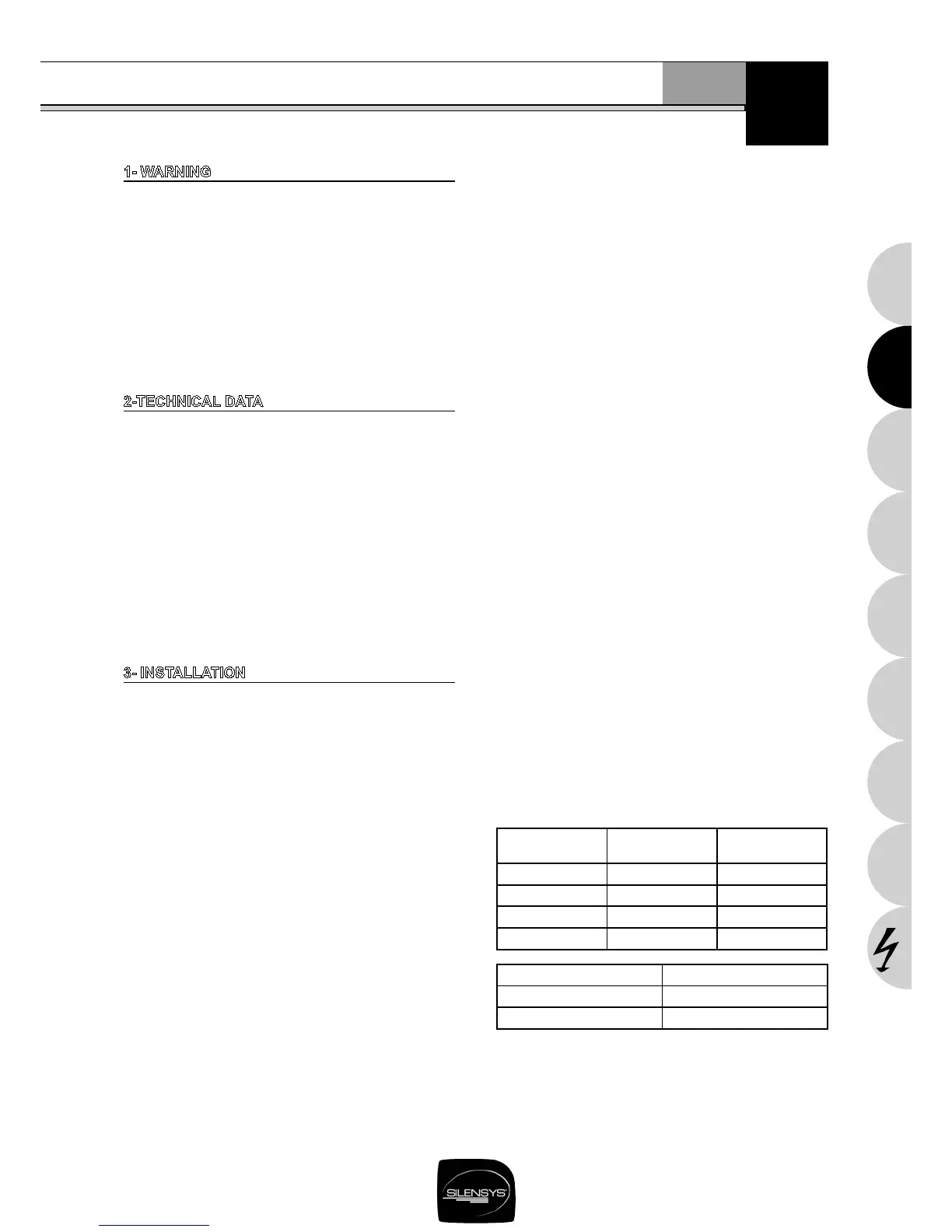

VALVE

CAJ/TAJ 70 to 85 Nm /

FH/TFH 114 to 126 Nm 70 to 85 Nm

TAG 114 to 126 Nm 114 to 126 Nm

VSA 114 to 126 Nm 70 to 85 Nm

0,75L to 9L 70 to 85 Nm

12L 114 to 126 Nm

Loading...

Loading...