CUTMASTER A60

SERVICE 5-16 Manual 0-4982

C. Input Capacitor PCB Test

1. Using an ohmmeter check continuity between the

following points:

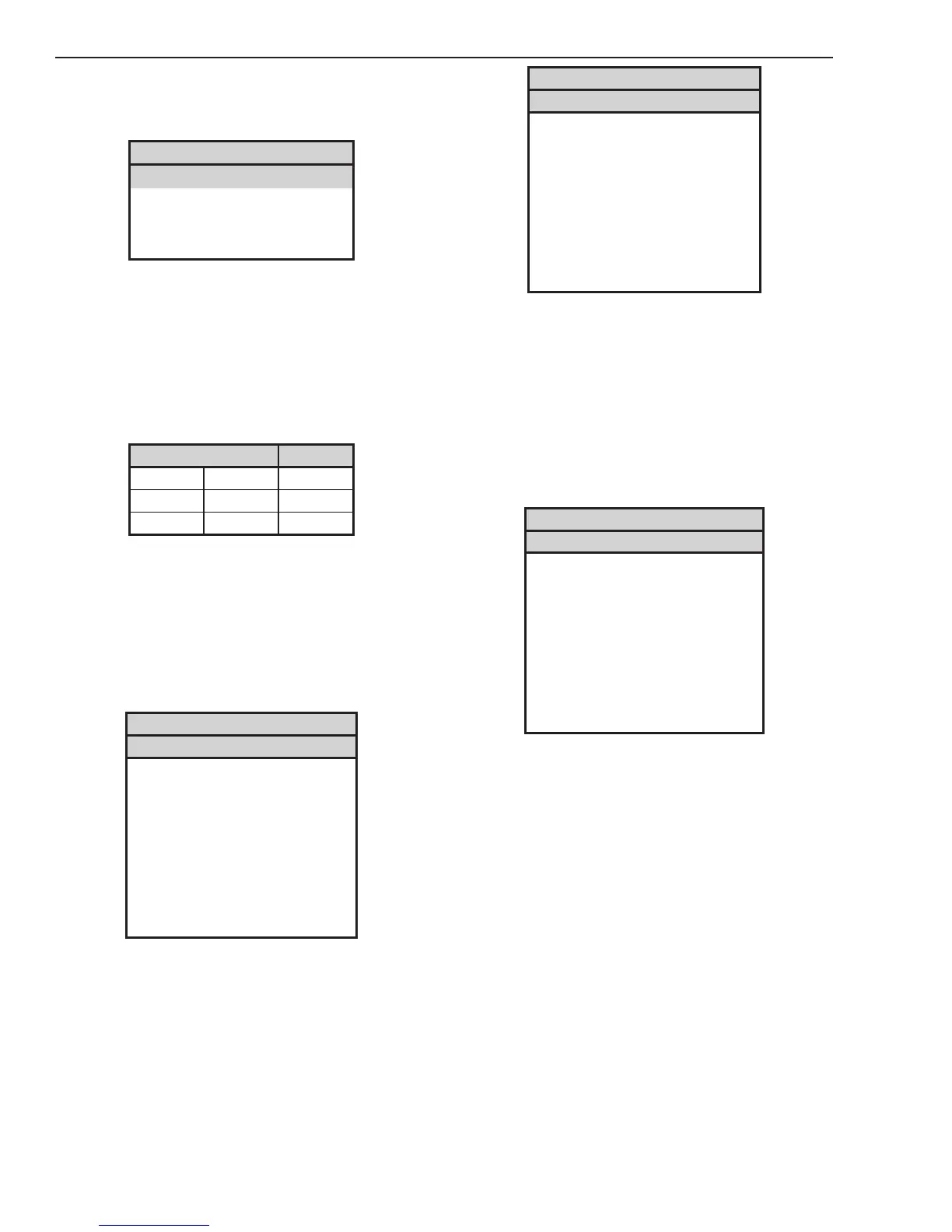

Input Capacitors

Meter + Meter - Indication

MTH 2 MTH 4 Charging

MTH 4 MTH 5 Open

MTH 6 MTH 5 Charging

Most meters will show a charging action. Initially a

low resistance will be shown and then the resistance

will start to increase. If the meter probes are reversed

the reading will decrease to zero, then start charging

in the opposite polarity.

2. If a short is found replace Capacitor PCB assem-

bly.

3. Check continuity between the following points

Input relays Indication

MTH 2 MTH 6 Open

MTH 4 MTH 6 Open

MTH 4 MTH 5 Open

4. If a short is found, replace Capacitor PCB assem-

bly

D. IGBT Modules Test

1. Disconnect transformer wires from Main PCB

terminals PRI 1 (A) and PRI 4 (D).

2. Using an ohmmeter perform the following

checks

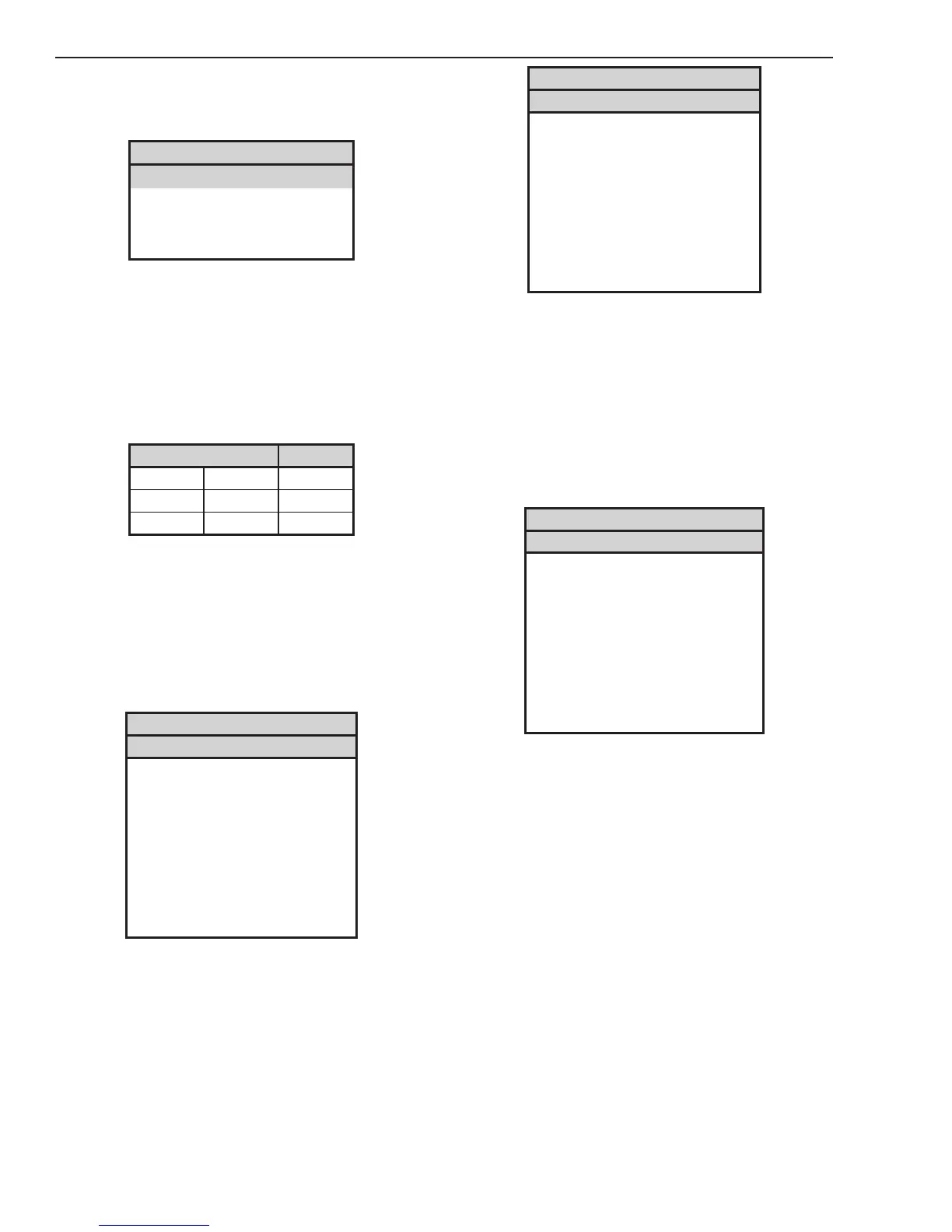

IGBT A

Meter (+) Meter (-) Indication

PRI 1 (A) MTH 2 ForwardBias

PRI 1 (A) MTH 4 Reverse Bias

MTH 2 PRI 1 (A) Reverse Bias

MTH 4 PRI 1 (A) ForwardBias

PRI 2 (B) MTH 2 ForwardBias

PRI 2 (B) MTH 4 Reverse Bias

MTH 2 PRI 2 (B) Reverse Bias

MTH 4 PRI 2 (B) ForwardBias

IGBT B

Meter (+) Meter (-) Indication

PRI 3 (C) MTH 6 ForwardBias

PRI 3 (C) MTH 5 Reverse Bias

MTH 6 PRI 3 (C) Reverse Bias

MTH 5 PRI 3 (C) ForwardBias

PRI 4 (D) MTH 6 ForwardBias

PRI 4 (D) MTH 5 Reverse Bias

MTH 6 PRI 4 (D) Reverse Bias

MTH 5 PRI 4 (D) ForwardBias

3. If the test reveals a failed component, replace

Main PCB and perform main contactor test – Sec-

tion 5.11-A. If no problem is found, reconnect the

transformer wires to Main PCB.

E. Output Diode Module Test

1. Disconnect transformer wires from Main PCB

terminal SEC 1.

2. Using an ohmmeter perform the tests in the

chart

Output Diode Module

Meter (+) Meter (-) Indication

SEC 1 WORK1 ForwardBias

SEC 1 CHOKE1 Reverse Bias

WORK1 SEC 1 Reverse Bias

CHOKE1 SEC 1 ForwardBias

SEC 2 WORK1 ForwardBias

SEC2 CHOKE1 Reverse Bias

WORK1 SEC2 Reverse Bias

CHOKE1 SEC 2 ForwardBias

3. If the test reveals a failed component, replace

Main PCB. If no problem is found, reconnect the

transformer wires to Main PCB.

F. Pilot IGBT Test

1. Disconnect wire from Main PCB terminal TIP1

2. Measure continuity on Main PCB between test

point GND1 to terminal TIP1

3. If the test reveals a failed component, replace

Main PCB. If no problem is found, reconnect wire

to Main PCB.

Signal Information

Many of the signal listed will be low voltage signals

that will be in one of two states: +12VDC (High) or

0VDC (Low) with respect to PCB common. When a

signal name is preceded by the “/” mark, it denotes

that the signal is an active low. For example:

/OVERTEMP – This signal is normally High but

when an over temperature fault exists, this line will

change state to a Low.

Loading...

Loading...