CUTMASTER A60

Manual 0-4982 5-7 SERVICE

D. Initial Set up Conditions

This section is to help isolate the defective circuit

before troubleshooting, identify symptoms, and test

the unit for proper operation. Follow the instructions

as given to identify the possible symptom(s) and the

defective circuit. After repairs are complete, run the

following tests again to verify that the unit is fully

operational.

1. Connect gas supply to rear of Power Supply.

2. Turn ON gas supply and set operating pressure

per pressure setting label on power supply.

3. Set the Power Supply controls as follows:

• ON/OFFSWITCHtoOFFposition

• TurnFUNCTIONCONTROLSWITCHtoSET

position

• CURRENTCONTROLPOTENTIOMETERto

MAXIMUM position, fully clockwise.

E. Main Input and Internal Power Test

1. Connect Primary Line power to the unit.

2. Turn the ON/OFF SWITCH ( SW1) to ON position

and observe the following:

• Softwareversionisdisplayed(Seesection5.04

Fault Indicators)

After approx. three (3) seconds

• InrushrelayonPCB1energizes,startingpre-

charging of working capacitors.

• W1energizes

• ACandGASIndicatorscomeON

• Gasows

• FansturnON

3. Adjust the pressure regulator to set the gas pres-

sure as specified in charts.

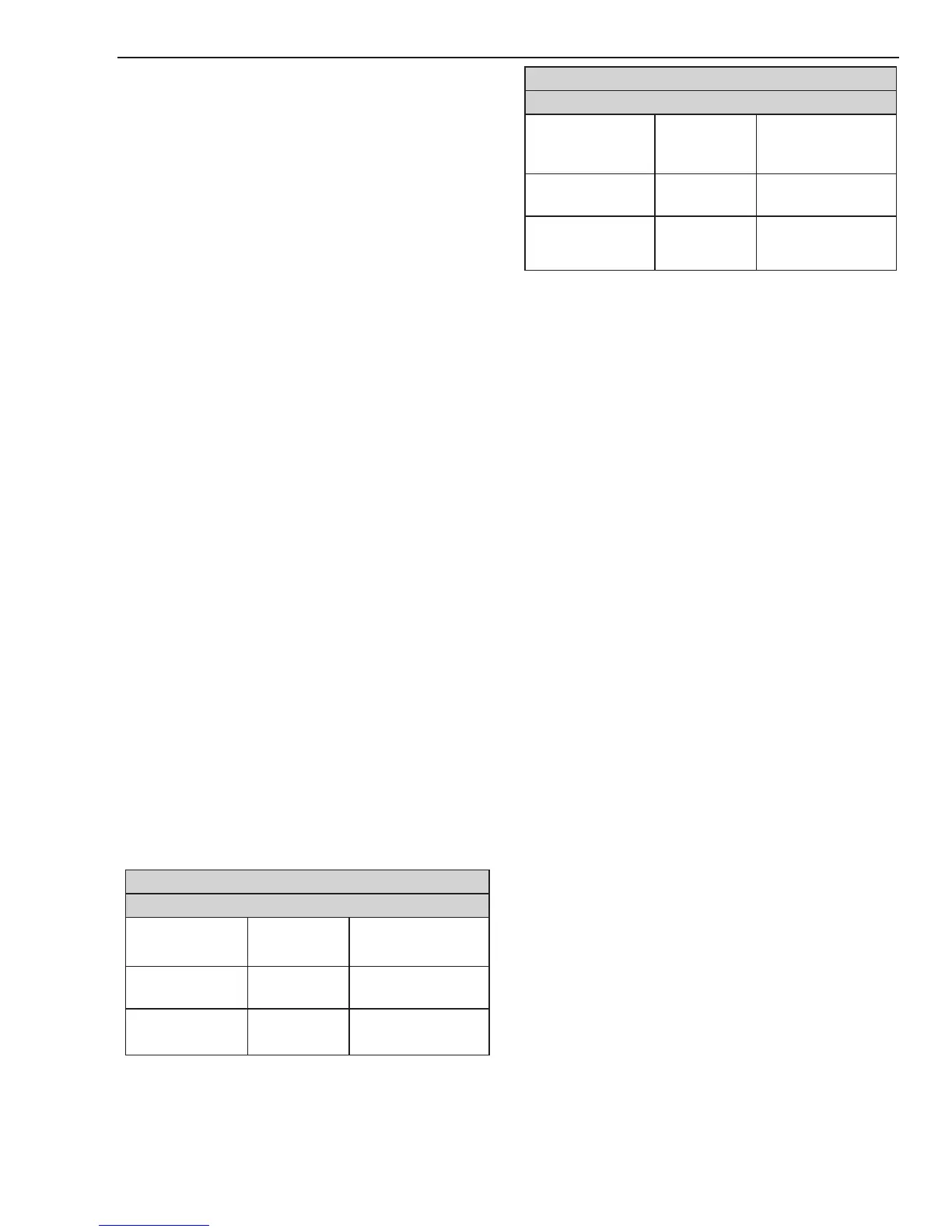

STANDOFF

CutMaster A-60 Gas Pressure Settings

Leads

Length

SL60

(Hand Torch)

SL100

(Mechanized Torch)

Up to 25'

(7.6 m)

75 psi

5.2 bar

70 psi

4.8 bar

Each additional

25' (7.6 m)

Add 5 psi

0.4 bar

Add 5 psi

0.4 bar

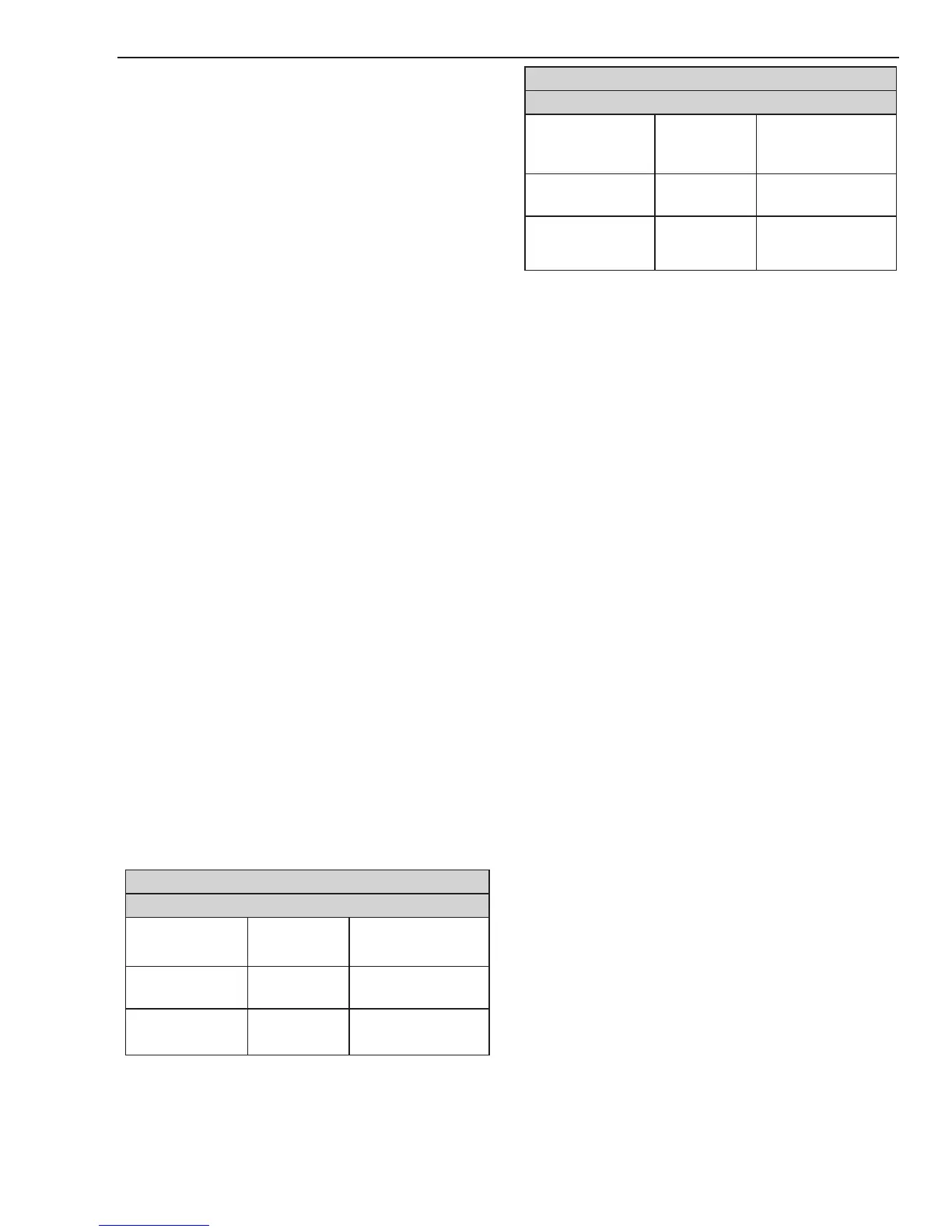

DRAG

CutMaster A-60 Gas Pressure Settings

Leads

Length

SL60

(Hand Torch)

SL100

(Mechanized Torch)

Up to 25'

(7.6 m)

80 psi

5.5 bar

75 psi

5.2 bar

Each additional

25' (7.6 m)

Add 5 psi

0.4 bar

Add 5 psi

0.4 bar

4. Turn FUNCTION CONTROL SWITCH to RUN

position

• SolenoidturnsOFF,gasstopsowing(pres-

sure display may increase slightly when gas

is not flowing)

This completes the Main Input and Internal Power Test.

If the above are all correct then proceed to the next section

"F. Pilot Arc Test". If the unit does not function as stated

above, then note the symptom and proceed to Section

"5.07, Main Input and Internal Power Problems".

F. Pilot Arc Test

1. Activate CNC Start signal, close Remote Pendant

switch or depress the Torch switch to establish a

pilot arc and note the following

• Gassolenoidopens

• Gasows

• Dependingontorchattached,afterasmuchas

two seconds the gas solenoid closes and gas

stops flowing momentarily, then gas solenoid

re-opens and gas resumes flowing

• DCLEDcomesON

• Pilotarcisestablished

2. Remove CNC start signal or release the Remote

Pendant or Torch switch

• Gascontinuestoow

• DCLEDgoesOFF

After 20 second post flow time

• Gassolenoidcloses

• Gasowstops

This completes the Pilot Arc Test. If the above are all

correct then proceed to the next section "G, Main Arc

and Controls Test". If the unit does not function as stated

above, then note the symptom and proceed to Section

"5.08, Pilot Arc Problems".

Loading...

Loading...