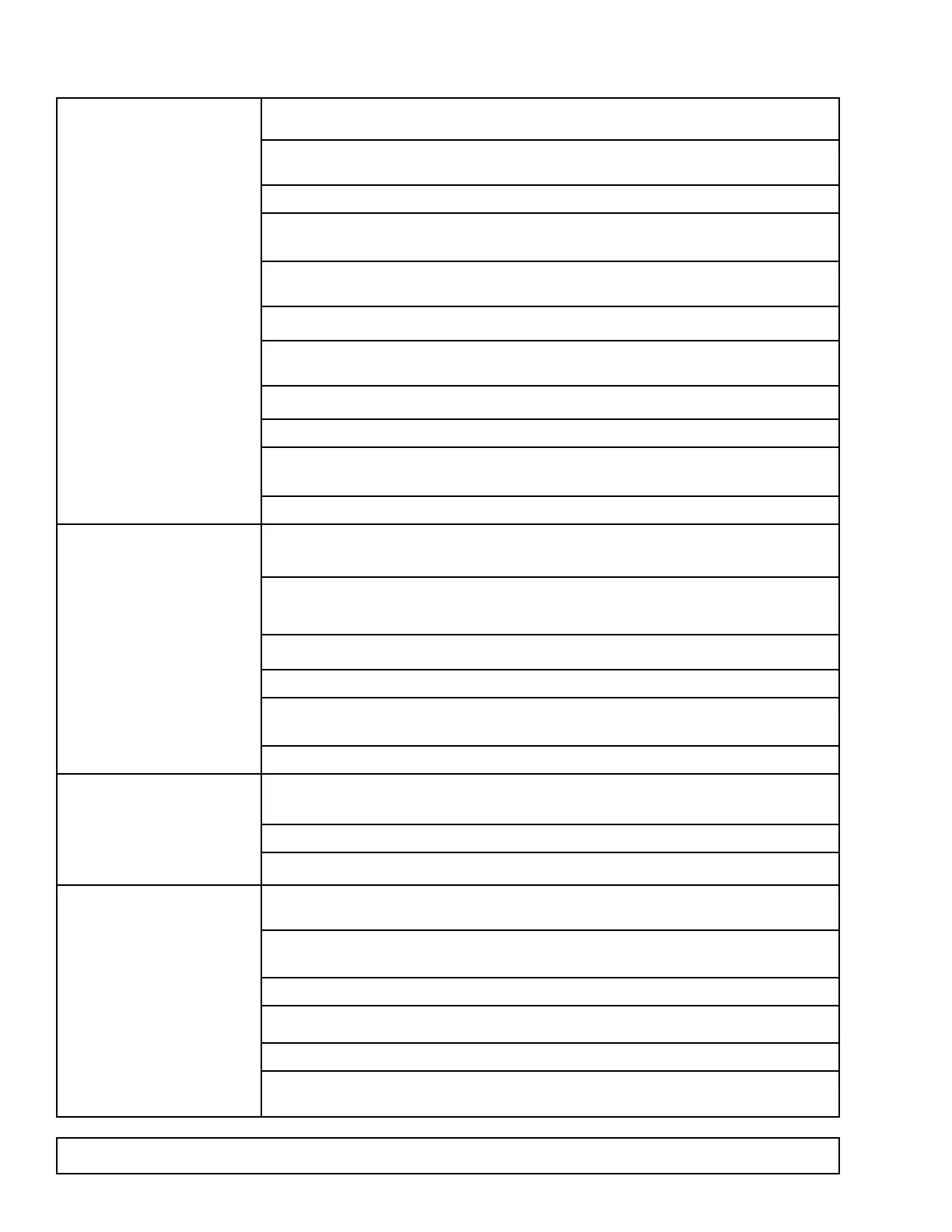

COMPRESSOR TROUBLESHOOTING GUIDES

COMPRESSOR STARTS Low line voltage. Bring up voltage.

& RUNS BUT CYCLES

ON PROTECTOR.

Additional current passing through Check for added fan motors and pumps

protector. connected to wrong side of protector.

Suction pressure too high. Check compressor for proper application.

Discharge pressure too high. Check ventilation, restrictions and over-

charge.

Protector weak. Check current - replace protector if

defective.

Running capacitor defective. Check capacitance. Replace if defective.

Stator partially shorted or grounded. Check resistances; check for ground.

Replace if defective.

Inadequate motor cooling. Correct cooling system.

Compressor tight. Check oil level. Check for binding condition.

Unbalanced line (three-phase). Check voltage of each phase. If not equal,

correct condition of unbalance.

Discharge valve leaking or broken. Replace valve plate.

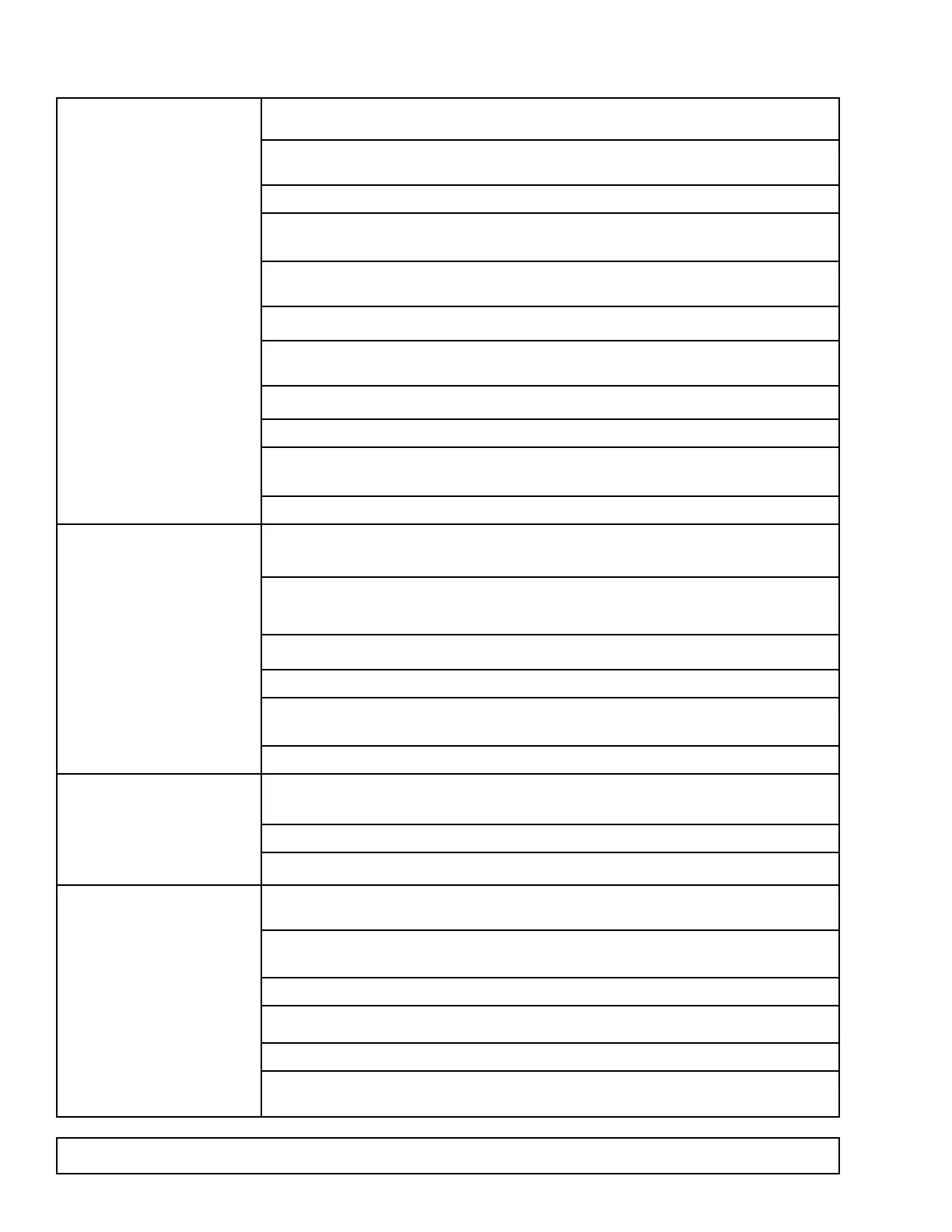

STARTING CAPACITORS Short cycling. Reduce number of starts to 20 or less per

BURNT OUT. hour.

Prolonged operation on starting Reduce starting load (install crankcase

winding. pressure limit valve), increase voltage if

low—replace relay if defective.

Relay contacts sticking. Clean contacts or replace relay.

Improper relay or incorrect relay setting. Replace relay.

Improper capacitor. Check parts list for proper capacitor rating:

mfd. and voltage.

Capacitor terminals shorted by water. Install capacitors so terminals won’t be wet.

RUNNING CAPACITORS Excessive line voltage. Reduce line voltage to not over 10% above

BURNT OUT. rating of motor.

High line voltage and light load. Reduce voltage if over 10% excessive.

Capacitor terminals shorted by water Install capacitors so terminals won’t be wet.

RELAYS BURNT OUT. Low line voltage. Increase voltage to not less than 10% above

motor rating.

Excessive line voltage. Reduce voltage to not more than 10%

above motor rating.

Incorrect running capacitor. Replace with correct capacitor.

Short cycling. Reduce number of starts per hour.

Relay vibrating. Mount relay rigidly.

Incorrect relay. Use relay recommended for specific motor

compressor.

60 MAINTENANCE & REPAIR

Loading...

Loading...