6 GENERAL INFORMATION

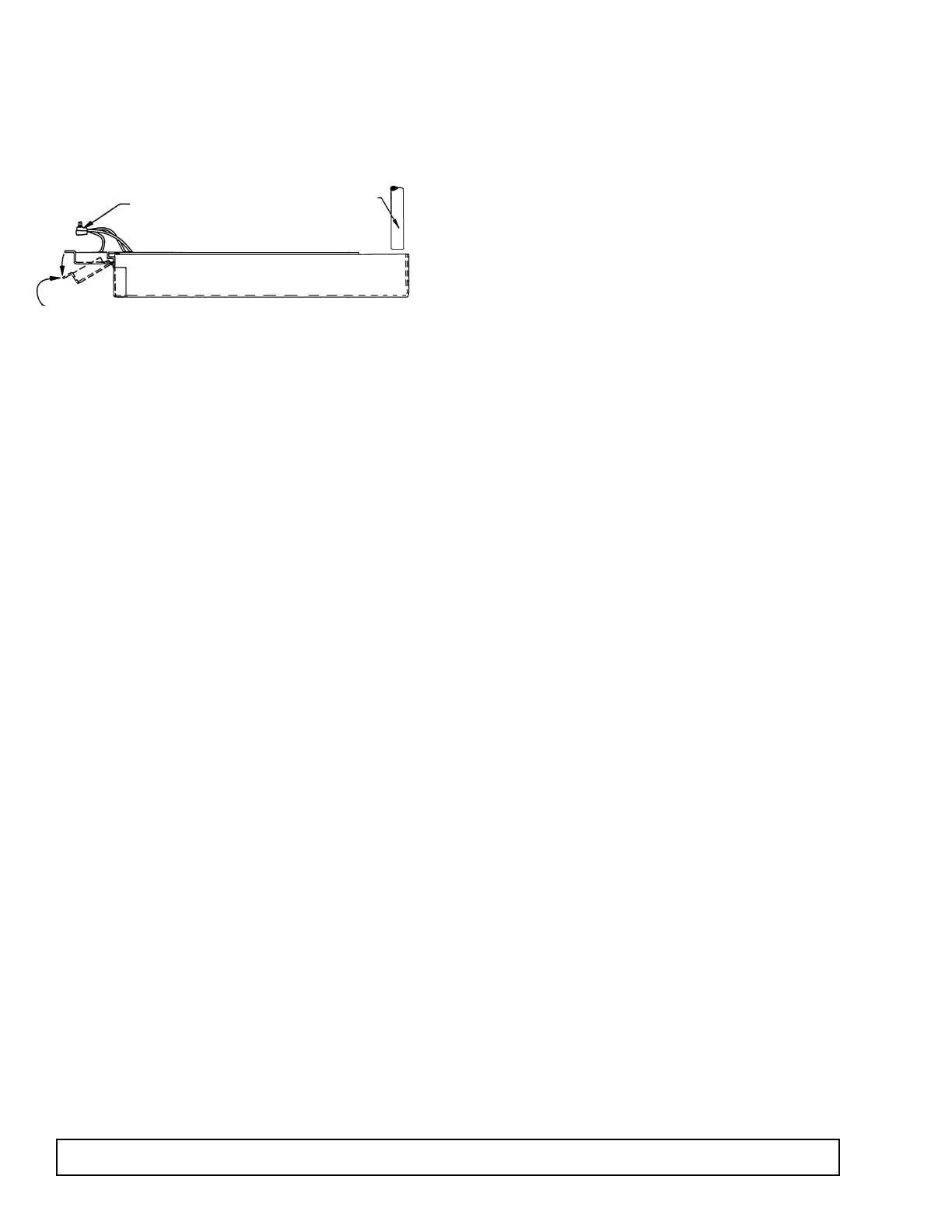

CONDENSATE PAN

INSTALLATION INSTRUCTIONS

MAKE SURE THE CABINET IS DISCONNECTED

FROM ITS POWER SOURCE

1. Remove and discard protective cover over electrical

receptacle on bottom of cabinet

2. Bend down front part of housing. (See above.)

3. Insert condensate evaporator pan assembly into the

slide supports on the underside of the cabinet by

pushing toward back of cabinet until it stops.

4. Plug supply cord into receptacle in underside of

cabinet.

5. Bend up front part of housing. Line up slot with

rivnut in cabinet bottom and insert thumbscrew

through slot onto rivnut in cabinet bottom. Insert

thumb screw through slot onto rivnut and tighten.

6. The assembly will now operate when power is sup-

plied to the cabinet.

7. Inspect rear of cabinet to ensure that the drain line

from the evaporator is properly positioned over the

condensate pan.

CABINET STARTUP

Once the cabinet has been located in its permanent

location and the proper power and grounding have

been provided, the following items must be checked or

completed:

1. Cut and remove the compressor hold-down band (if

applicable) so the compressor “floats” freely.

2. Check for traces of oil on the compressor pan which

could mean a broken or leaking refrigeration line.

UNDER NO CIRCUMSTANCE SHOULD THE

COMPRESSOR BE STARTED WHEN OIL IS PRE-

SENT UNTIL INSPECTED BY A SERVICE TECH-

NICIAN.

3. INSPECT THE FACTORY WIRING FOR

TERMINALS THAT MIGHT HAVE VIBRATED

LOOSE IN SHIPPING. TIGHTEN ALL SCREW-

TYPE TERMINALS.

4. Check the refrigeration lines to see that they are

“free” and no damage was done during shipping.

5. Check fan blade(s) for “free” operation.

6. Turn on the main power switch. Once the compressor

starts, the voltage should be checked at the compres-

sor terminals to determine if there is proper voltage to

the compressor. The voltage should not exceed 10%

above or below the rated compressor voltage.

EXAMPLE: If the voltage reads 115 volts with no load

and it drops below 103 volts when the compressor

starts, it may indicate that the supply wiring is too

small or that the wire run is too long.

7. Make sure that the drain line has not been dis-

lodged or broken during shipping and that the drain

trap terminates properly in the condensate pan or

floor drain. (See

Condensate Pan on top mounted

compressor.)

8. Listen for any unusual noise such as lines vibrating,

etc. Correct problem by tightening screws, slightly

bending tubing, etc.

9. Check proper tension on doors. (See Door Torque

Adjustment.)

10. Cabinet should not be loaded with product until

cabinet has operated for 24 hours and reached

desirable storage temperature.

EXPORT MODELS

Export model cabinets come equipped with an auto

transformer located in the unit compartment. The

selector switch can be set to various customer voltage

requirements - Factory Setting: Mid position for an

incoming voltage between 212V and 238V.

PRIOR TO STARTING THE CABINET

Supply voltage must be checked in order to determine

the correct position of the variable voltage switch

located on the auto transformer. This will ensure the

cabinet is operating at the correct optimum voltage. In

the event the transformer supply line plug does not

match the electrical outlet, the plug can be changed to

one with equal voltage-amperage rating.

Refer to page 41 for transformer layout.

DRAIN LINE FROM

EVAPORATOR - SEE

NOTE #7.

SUPPLY CORD

Loading...

Loading...