31

K10CR1 Cage Rotation Stage

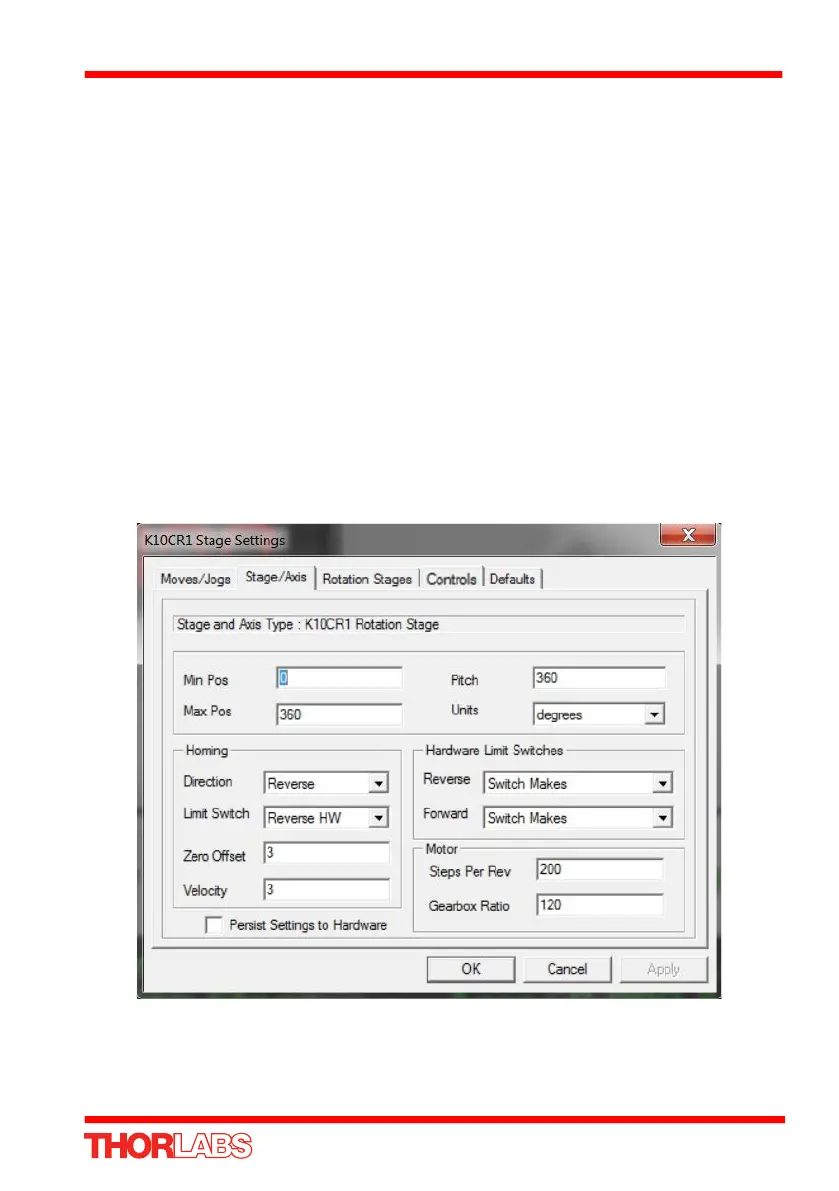

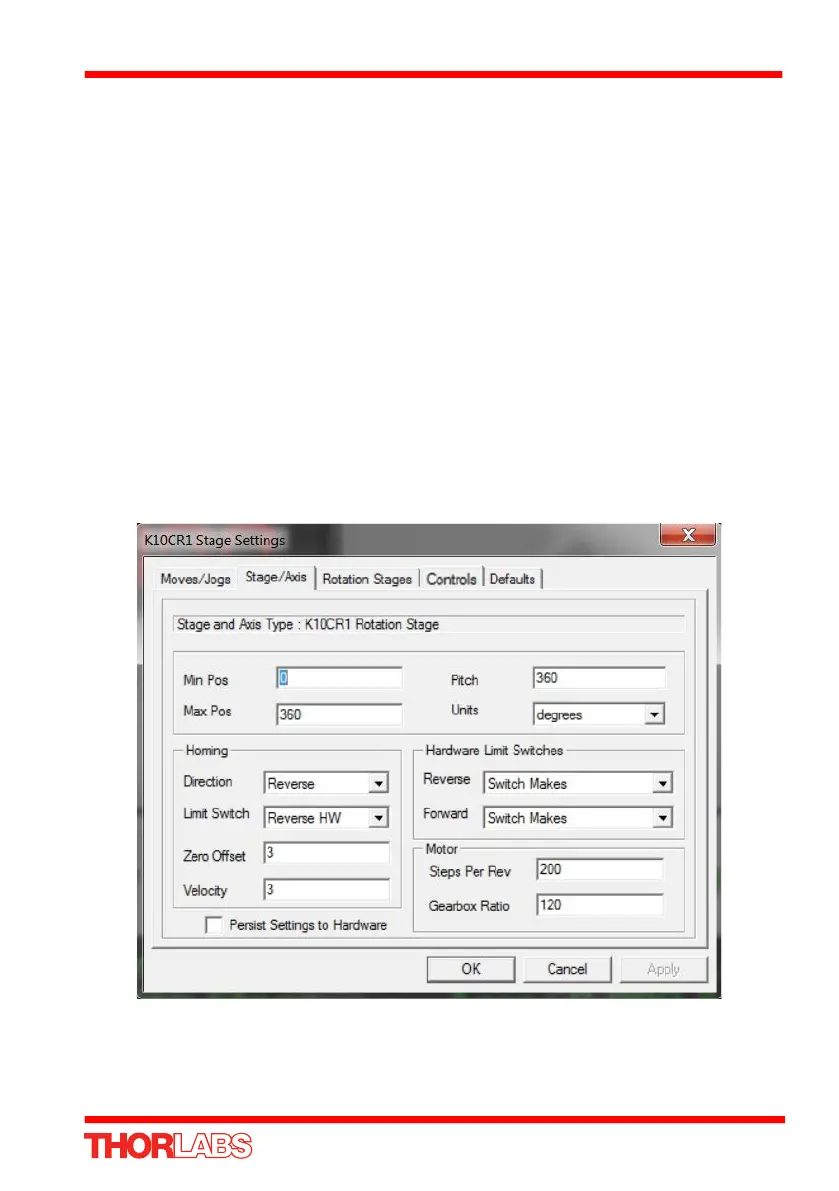

5.12 Minimum and Maximum Position Settings

There are no mechanical end stops on the K10CR1 stage and theoretically, the total

(accumulative) angle of the motion could be arbitrarily large. In practice, however, the

integer arithmetic used for the position counter poses a restriction on the range of

position values that can be represented. To avoid integer overflow and underflow

problems, the target position is checked against the limits displayed in the Min Pos

and Max Pos values. This check is done to ensure that the position counter always

shows a correct value. For the K10CR1 stage, the Min Pos and Max Pos limits are

equivalent to around ±43 full rotations (15,480 degrees).

In applications where continuous rotation is required, the Move At Velocity command

can be used. This command does not constrain the angle to the Min Pos and Max Pos

range and the continuity of the movement will not be interrupted until a Stop command

is issued. However, when the integer representing the position counter overflows, the

position value will flip sign and will no longer be correct. Any application commanding

continuous moves for long period of times must take this into account and accept that

once the Min Pos and Max Pos position is exceeded, the value displayed may no

longer be correct. Homing the stage will zero the position count and correct the

display.

Fig. 5.14 K10CR1 Stage/Axis Settings Tab

Loading...

Loading...