3

CheckingFluidLevels

NoPartsRequired

Procedure

1.Checkthehydraulicuidlevelbeforestartingthe

engine;refertoCheckingtheHydraulicSystem(page

30).

2.Checktheengineoillevelbeforeandafterstartingthe

engine;refertoCheckingtheEngineOilLevel(page

30)

.

3.Checkthecoolingsystembeforestartingtheengine;

refertoCheckingtheCoolingSystem(page53).

4

ActivatingandChargingthe

Battery

NoPartsRequired

Procedure

Useonlyelectrolyte(1.265SpecicGravity)tollbattery

initially.

1.Removethebatteryfromthemachine.

Important:Donotaddelectrolytewhilethe

batteryisinthemachine.Youcouldspillit,

causingcorrosion.

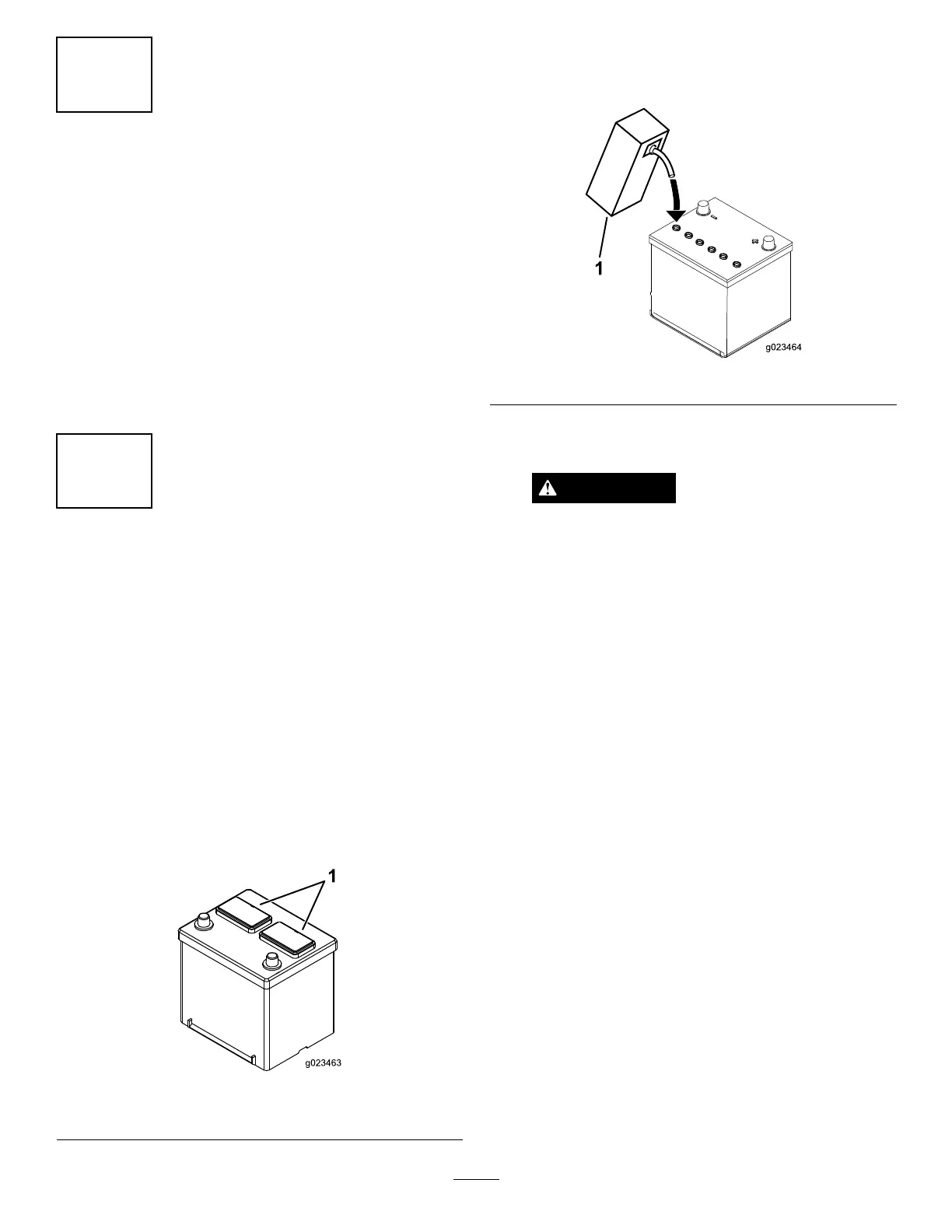

2.Cleanthetopofthebatteryandremovetheventcaps

(Figure5).

Figure5

1.Ventcaps

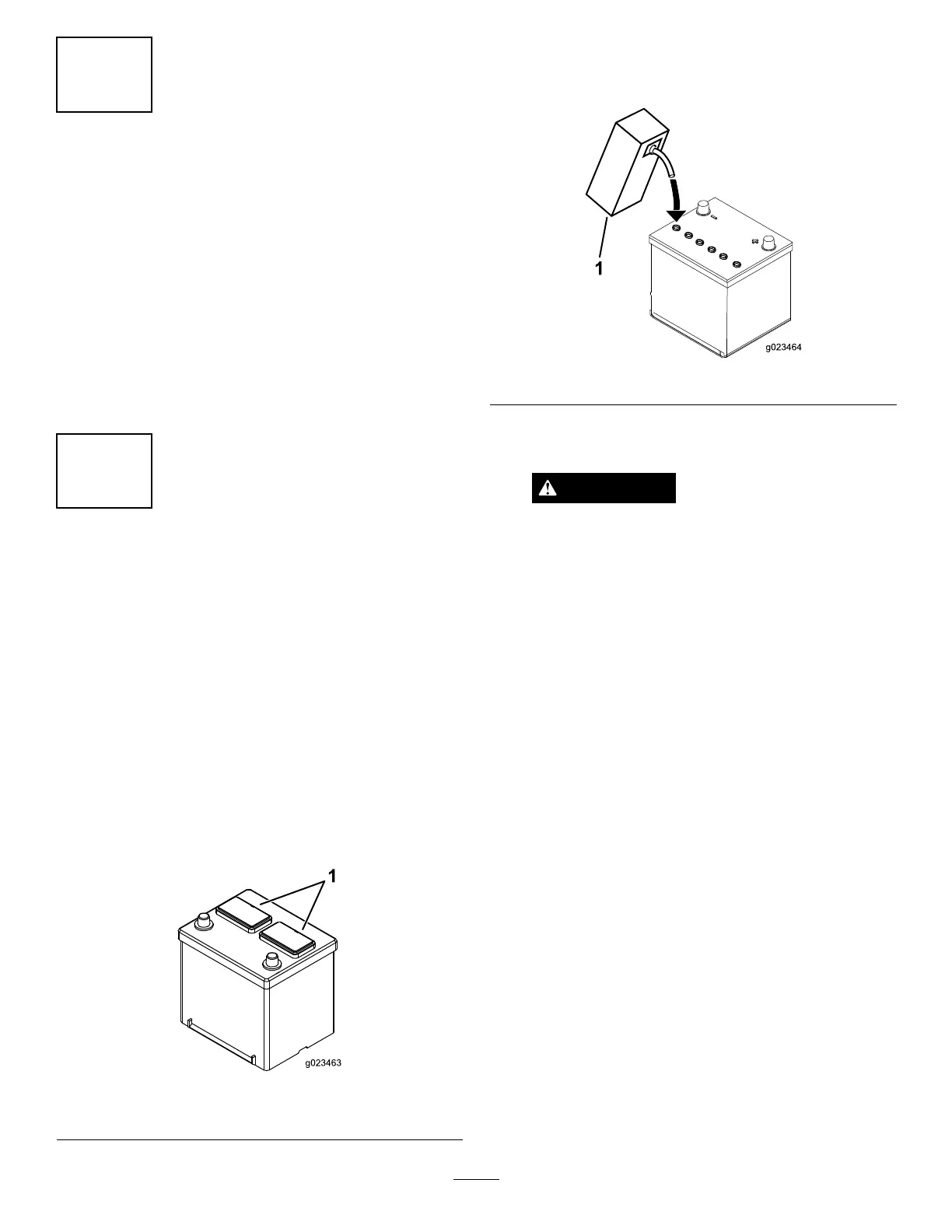

3.Carefullylleachcellwithelectrolyteuntiltheplates

arecoveredwithabout6mm(1/4inch)ofuid(Figure

6).

Figure6

4.Allowapproximately20to30minutesforthe

electrolytetosoakintotheplates.

WARNING

Chargingthebatteryproducesgassesthat

canexplode,andcouldcauseseriousinjury

ordeath.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

5.Rellasnecessarytobringtheelectrolytetowithin

about6mm(1/4inch)ofthebottomofthellwell

(Figure6).

6.Connecta3-to-4ampbatterychargertothebattery

posts.Chargethebatteryatarateof3to4amps

untilthespecicgravityis1.25orhigherandthe

temperatureisatleast16°C(60°F)withallcells

gassingfreely.

7.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

Note:Afterthebatteryhasbeenactivated,add

onlydistilledwatertoreplacenormalloss,although

maintenance-freebatteriesshouldnotrequirewater

undernormaloperatingconditions.

17

Loading...

Loading...