Note:Makesurethatthebrake-shaftsensordoesnot

contacttheswitchplunger.

5.Securetheswitchjamnuts.

6.Testtheadjustmentasfollows:

A.Ensurethattheparkingbrakeisengagedandyou

arenotsittingontheseat,thenstarttheengine.

B.Movethecontrolleversoutoftheneutrallocked

position.

Theengineshouldstop.Ifnot,recheckthe

adjustmentyoumadetotheswitch.

7.Installthefrontpanel.

BeltMaintenance

CheckingtheAlternatorBelt

ServiceInterval:Every100hours

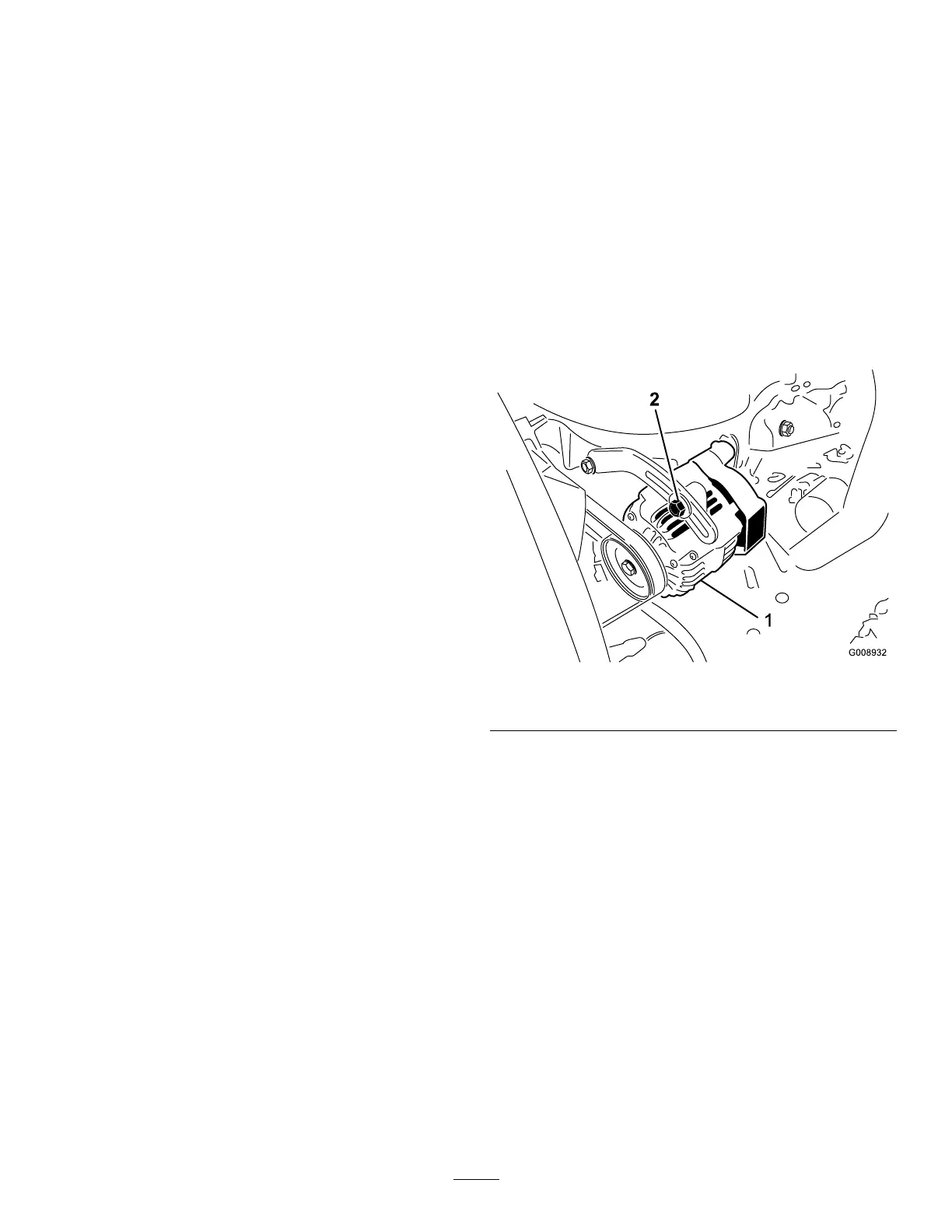

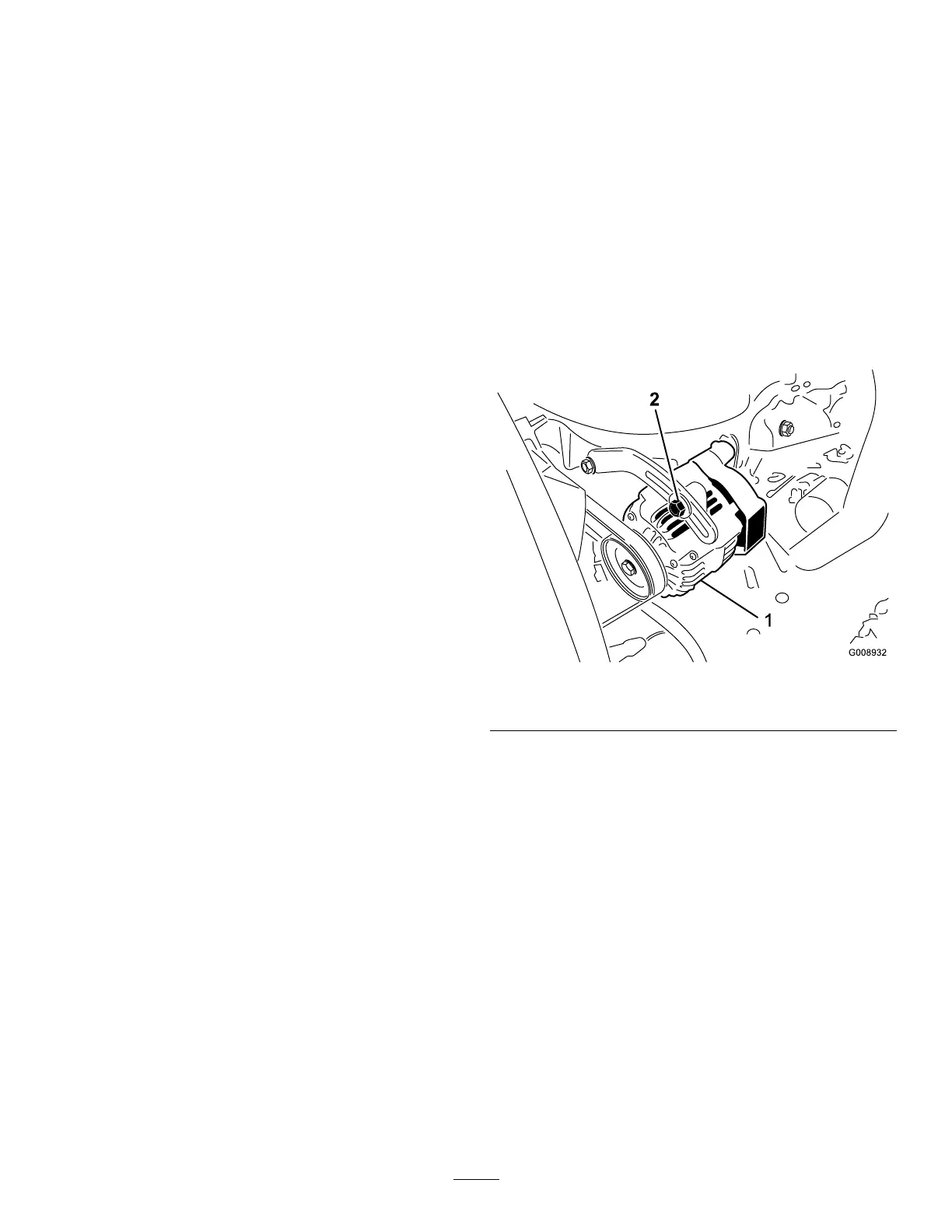

Checktheconditionandtensionofthebelts(Figure77)after

every100operatinghours.

1.Propertensionwillallow10mm(3/8inch)deection

whenaforceof44N(10lb.)isappliedonthebelt

midwaybetweenthepulleys.

2.Ifthedeectionisnot10mm(3/8inch),loosenthe

alternatormountingbolts(

Figure77).Increaseor

decreasethealternatorbelttensionandtightenthe

bolts.Checkthedeectionofthebeltagaintoensure

thatthetensioniscorrect.

Figure77

1.Mountingbolt2.Alternator

ReplacingtheBladeDrive

Belts

ServiceInterval:Every50hours

Thebladedrivebelts,tensionedbythespringloadedidler

pulleys,areverydurable.However,aftermanyhoursofuse,

thebeltswillshowsignsofwear.Signsofawornbeltare:

squealingwhenbeltisrotating,bladesslippingwhencutting

grass,frayededges,burnmarksandcracks.Replacethebelts

ifanyoftheseconditionsareevident.

1.Lowerthecuttingunittothe1inchheight-of-cut

setting,movethethrottlelevertotheSlowposition,

stoptheengine,settheparkingbrake,andremovethe

ignitionkey.

2.Removethebeltcoversfromthetopofthecuttingunit

andsetthecoversaside.

3.Usingabreakerbarorsimilartool,movetheidler

pulleyforthetopbelt(Figure78)awayfromthetop

55

Loading...

Loading...