DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every50hours

Checkthepressureafterevery50operatinghoursormonthly,

whicheveroccursrst(Figure72).

Maintaintheairpressureinthefrontandreartires.The

correctairpressureis124kPa(18psi)inthereartiresand

172kPa(25psi)inthecasterwheels.Uneventirepressure

cancauseanunevencut.Checkthetireswhentheyarecold

togetthemostaccuratepressurereading.

Figure72

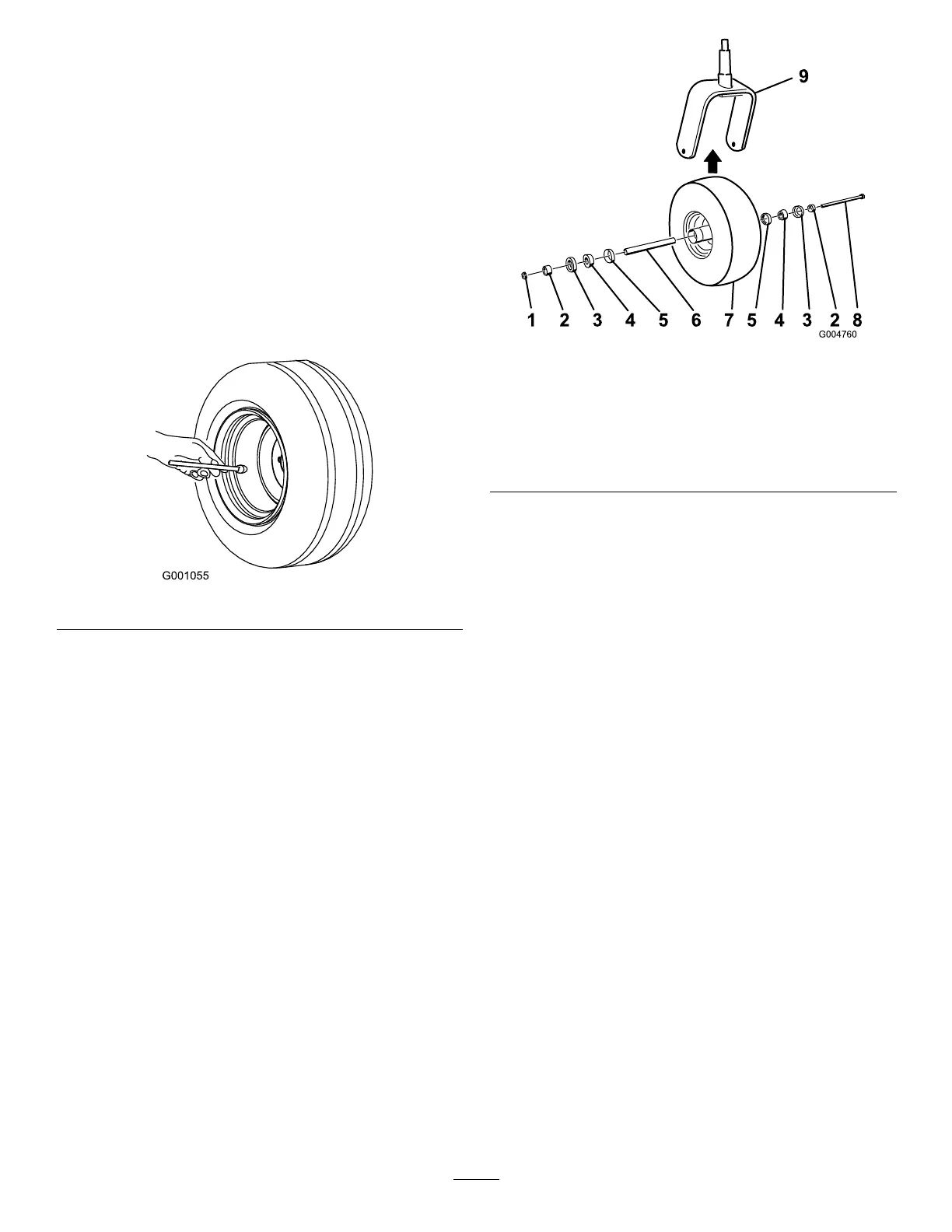

ReplacingtheCasterWheels

andBearings

1.Obtainanewcasterwheelassembly,conebearings,and

bearingsealsfromyourAuthorizedToroDistributor.

2.Removethelocknutfromtheboltholdingthecaster

wheelassemblybetweenthecasterfork(Figure73).

Figure73

1.Nut

6.Spacer

2.Bearingspacer

7.Casterwheel

3.Outerbearingseal

8.Axlebolt

4.Conebearing9.Casterfork

5.Innerbearingseal

3.Graspthecasterwheel,andslidetheboltoutofthe

forkorpivotarm.

4.Discardtheoldcasterwheelandbearings.

5.Assemblethecasterwheelbypushingthecone

bearingsandseals,packedwithgrease,intothewheel

hub,positionedasshowninFigure73.

6.Slidethespacerintothewheelhubthroughthe

bearings,captivatingthespacerinsidethewheelhub

with2bearingspacers.

Important:Ensurethattheseallipsarenot

foldedinward.

7.Installthecaster-wheelassemblybetweenthecastor

forkandsecureitinplacewiththeboltandlocknut.

8.Tightenthenutuntilthewheelnolongerspinsfreely,

thenbackitoffjustuntilthewheelspinsfreely.

9.Attachagreaseguntothegreasettingonthe

casterwheelandllitwithNo.2general-purpose,

lithium-basedgrease.

52

Loading...

Loading...