DriveSystem

Maintenance

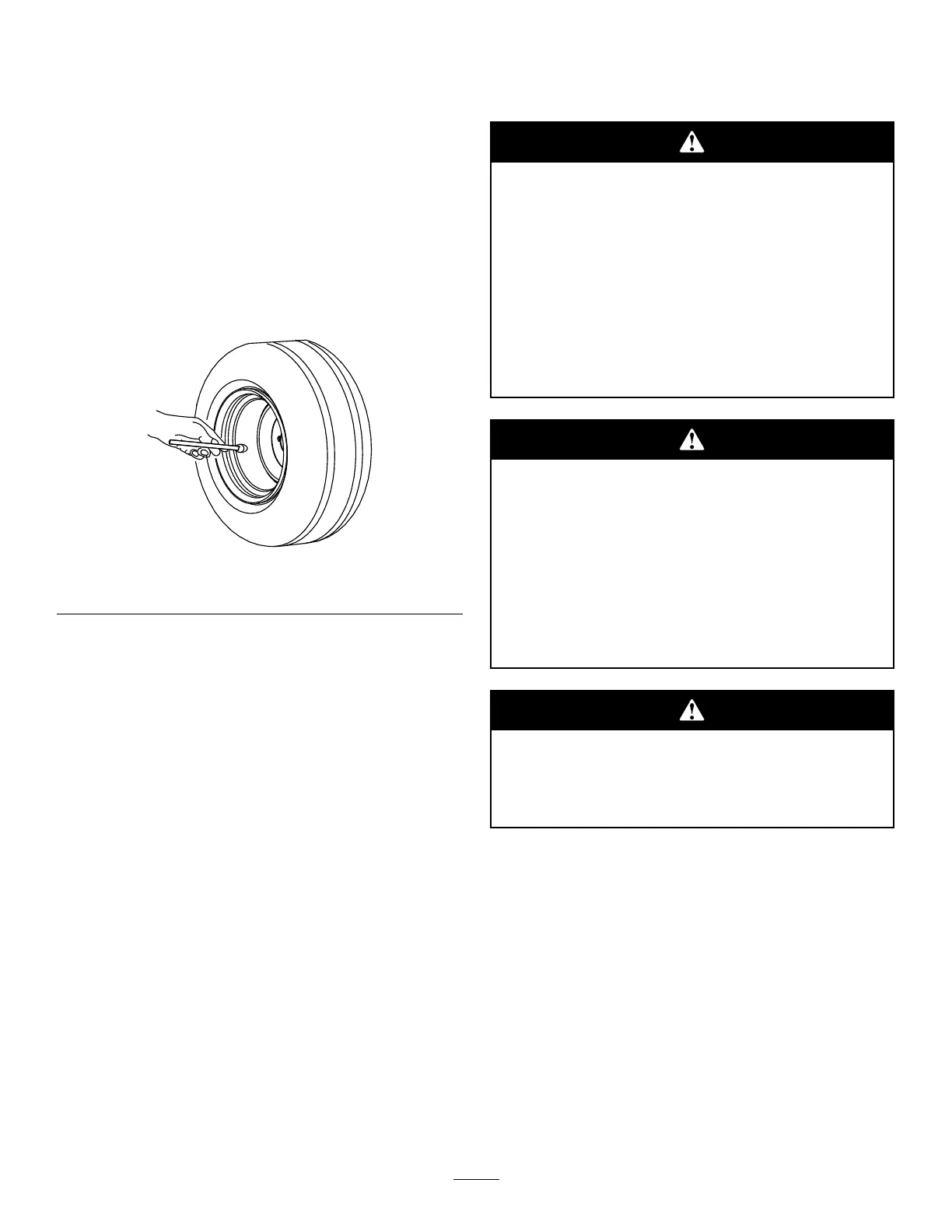

CheckingtheTirePressure

ServiceInterval:Every50hours

Maintaintheairpressureinthetiresat35psi(241kPa)

(Figure42).Uneventirepressurecancausethetracksto

slip.Ifthetracksslip,evenlyincreasethetirepressure

ineachtireby10psi(69kPa)untilthetracksnolonger

slipwhendriving.Donotexceed50psi(345kPa)in

eachtire.

Figure42

Note:Checkthetireswhentheyarecoldtogetthe

mostaccuratepressurereading.

CoolingSystem

Maintenance

Dischargeofhotpressurizedcoolantor

touchinghotradiatorandsurroundingparts

cancausesevereburns.

•Donotremovetheradiatorcapwhenthe

engineishot.Alwaysallowtheengineto

coolatleast15minutesoruntiltheradiator

capiscoolenoughtotouchwithoutburning

yourhandbeforeremovingtheradiatorcap.

•Donottouchradiatorandsurroundingparts

thatarehot.

Therotatingfananddrivebeltcancause

personalinjury.

•Donotoperatethemachinewithoutthe

coversinplace.

•Keepngers,handsandclothingclearof

rotatingfananddrivebelt.

•Shutofftheengineandremovetheignition

keybeforeperformingmaintenance.

Swallowingenginecoolantcancausepoisoning.

•Donotswallowenginecoolant.

•Keepoutofreachfromchildrenandpets.

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily—Checkthe

enginecoolantlevel.

Thecoolingsystemislledwitha50/50solutionof

waterandpermanentethyleneglycolantifreeze.Check

thelevelofthecoolantintheexpansiontankatthe

beginningofeachdaybeforestartingtheengine.The

capacityofthecoolingsystemis6quarts(7.5l).

36

Loading...

Loading...