HydraulicSystem

Maintenance

Thereservoirislledatthefactorywith

approximately5quarts(4.7l)ofhighqualitytractor

transmission/hydraulicuid.Therecommended

replacementuidisasfollows:

ToroPremiumTransmission/HydraulicTractorFluid

(Availablein5gallonpailsor55gallondrums.Seeparts

catalogorTorodistributorforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,

Mobil®424hydraulicuidmaybeused.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions.

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein2/3oz.(20ml)

bottles.Onebottleissufcientfor4-6gal(15-221)of

hydraulicoil.Orderpartnumber44-2500fromyour

authorizedTorodistributor.

CheckingtheHydraulicFluid

Level

ServiceInterval:Beforeeachuseordaily

1.Positionthemachineonalevelsurface.Placethe

controlsintheneutrallockedpositionandstartthe

engine.RunengineatlowestpossibleRPMtopurge

thesystemofair.DonotengagethePTO.Raise

thedecktoextendliftcylinders,stoptheengine,and

removethekey.

2.Raisetheseattoaccessthehydraulicuidtank.

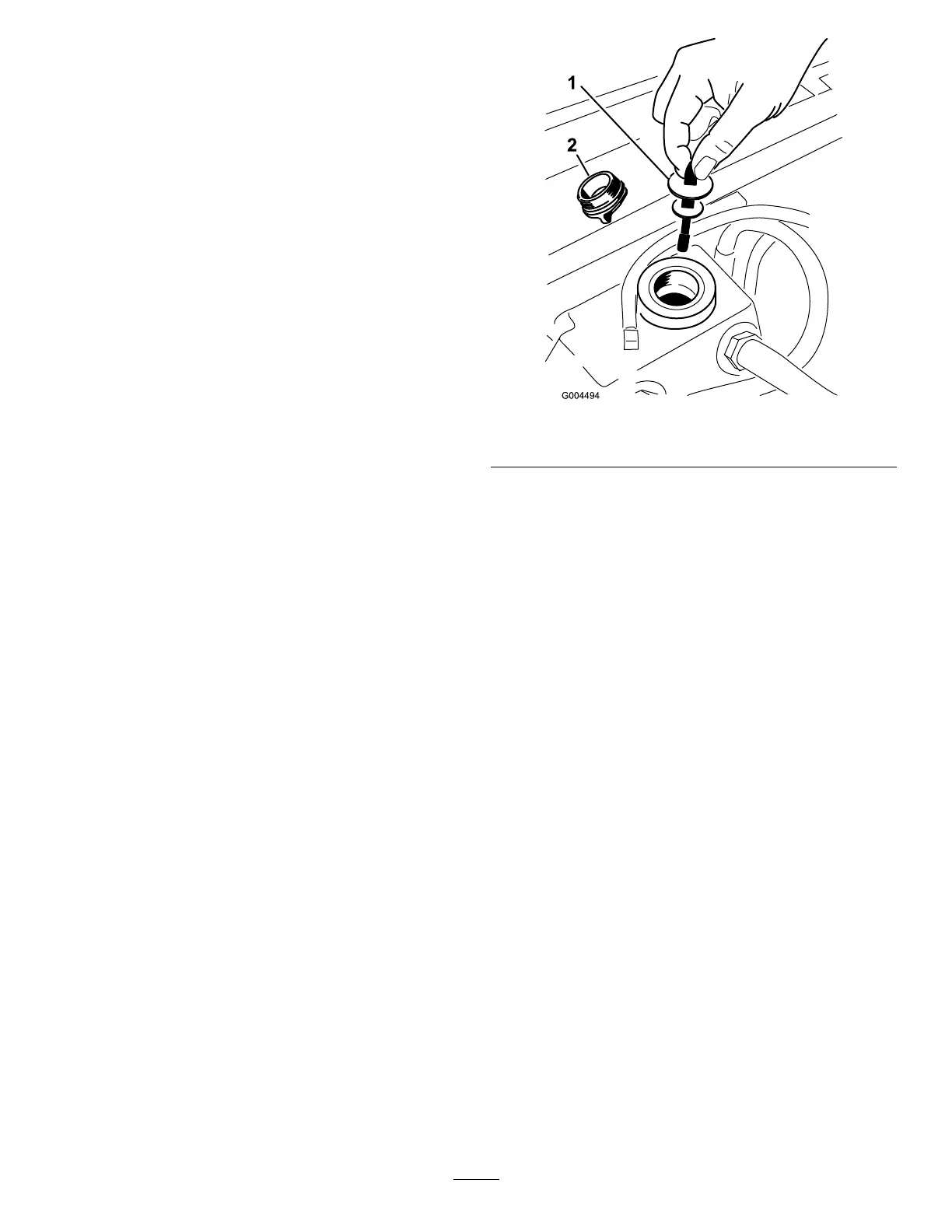

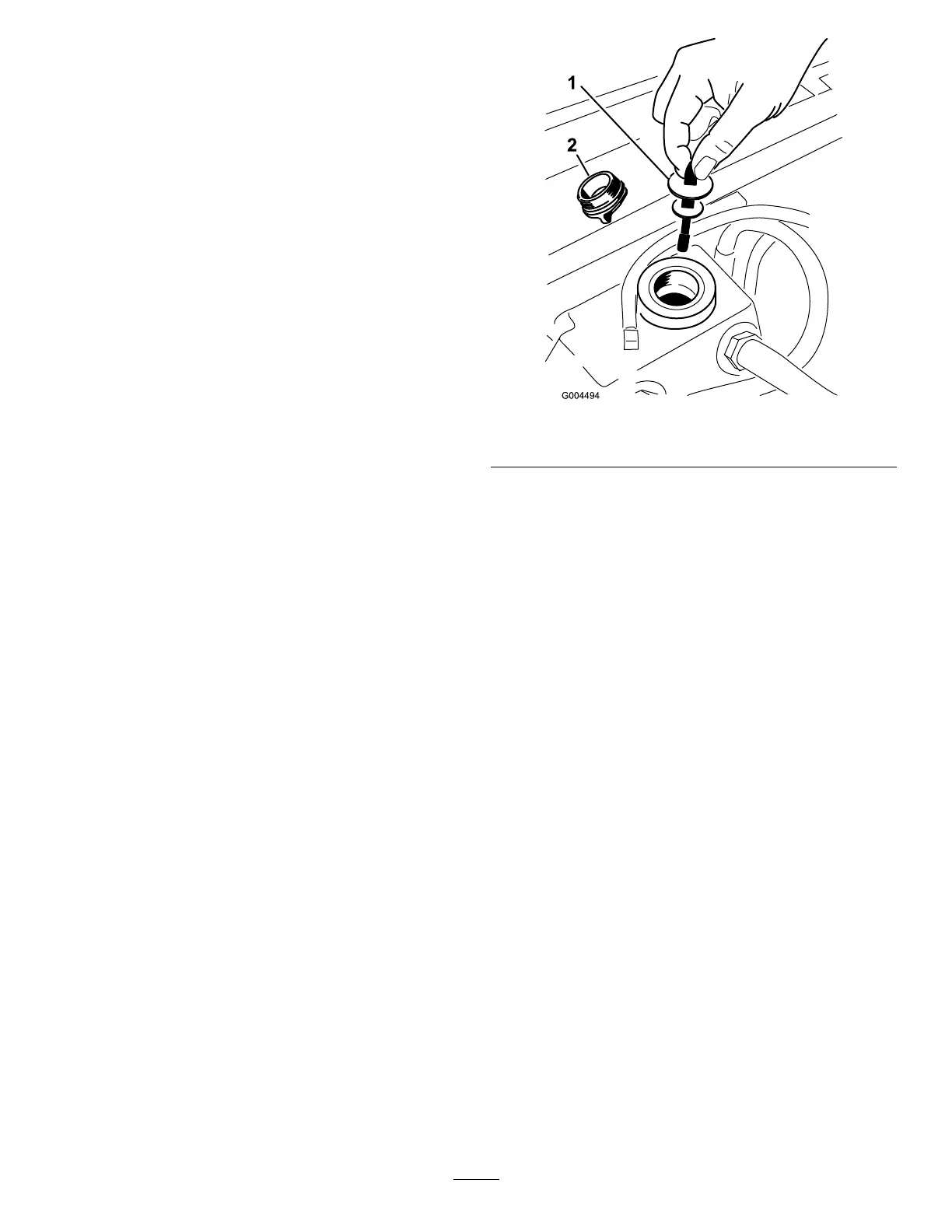

3.Removethehydraulicllcap(Figure57)fromller

neck.

Figure57

1.Dipstick2.Fillcap

4.Removethedipstickandwipeitwithacleanrag

(Figure57).

5.Placethedipstickintothellerneck;thenremoveit

andchecklevelofuid(Figure57).

Iflevelisnotwithinnotchedareaofthedipstick,

addenoughhighqualityhydraulicuidtoraiselevel

towithinthenotchedarea.Donotoverll.

6.Replacethedipstickandthreadthellcap

nger-tightontollerneck.

7.Checkallhosesandttingsforleaks.

ChangingtheHydraulicOil

AndFilter

ServiceInterval:Aftertherst200hours

Every800hours

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

3.Placealargepanunderthehydraulicreservoirand

transmissioncaseandremovetheplugs,drainingall

ofthehydraulicuid(Figure58).

43

Loading...

Loading...