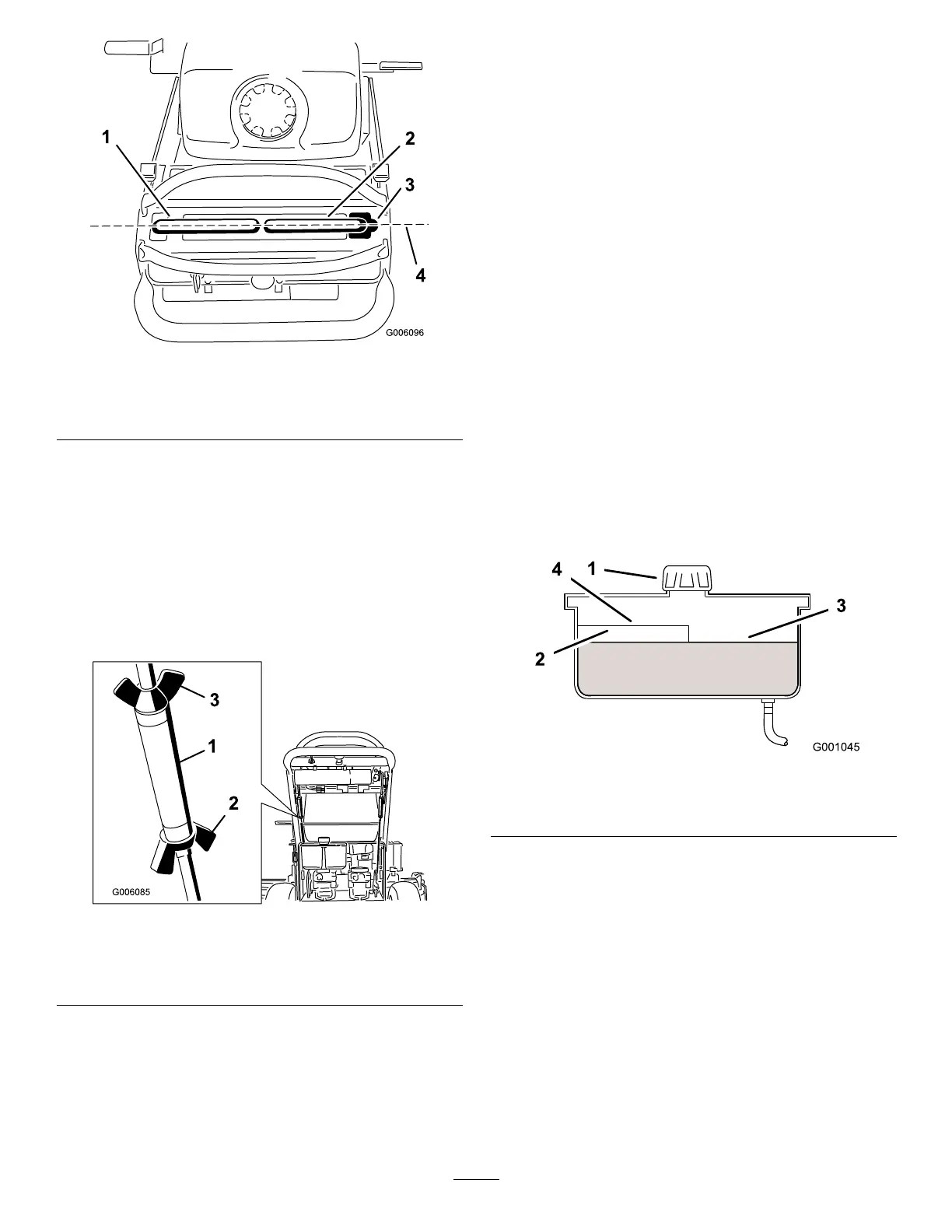

Figure57

1.Leftmotioncontrollever

3.Neutrallockedposition

2.Rightmotioncontrollever4.Alignthecontrollevers

fronttobackhere

2.Loosenthewingnutsontherightcontrolrodand

rotatetheturnbuckleinorouttoensuretheright

sidecontrolleveriscenteredintheneutrallock

position.Securetheturnbuckleinpositionwiththe

wingnuts(Figure58).

3.Loosenthewingnutsontheleftcontrolrodand

rotatetheturnbuckleinorouttochangethetracking.

Securetheturnbuckleinpositionwiththewingnuts

(

Figure58).

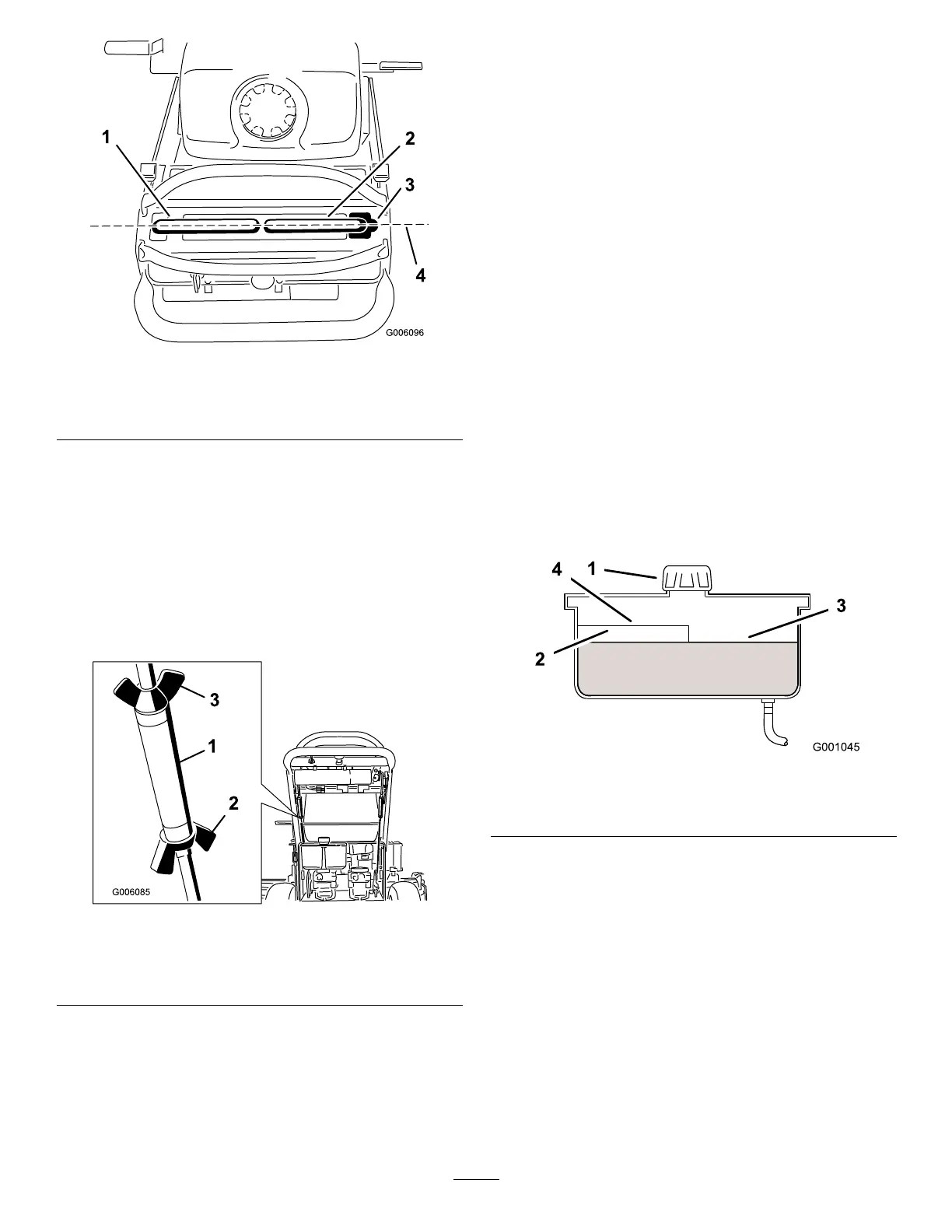

Figure58

1.Turnbuckle

3.Topwingnut(lefthand

threaded)

2.Bottomwingnut

4.Checkforpropertracking.Adjusttheleftcontrol

rodifachangeisneeded.RefertoAdjustingthe

TrackingintheOperationSection.

HydraulicSystem

Maintenance

ServicingtheHydraulic

System

CheckingtheHydraulicFluid

ServiceInterval:Aftertherst8hours

Every25hours

Note:Therearetwowaysofcheckingthehydraulicoil.

Oneiswhentheoiliswarmandoneiswhentheoilis

cold.Thebafeinsidethetankhastwolevelsdepending

iftheoiliswarmorcold.

1.Positionmachineonalevelsurface.

2.Disengagethepowertakeoff(PTO)andshutoff

theengine.

3.Waitforallmovingpartstostopbeforeleavingthe

operatingpositionandthensettheparkingbrake.

4.Cleanareaaroundcapandllerneckofhydraulic

tank(

Figure59).

Figure59

1.Cap3.Colduidlevel-full

2.Bafe4.Hotuidlevel-full

5.Removecapfromllerneck.Lookinsidetocheck

theuidlevelinthereservoir.(Figure59).

6.Adduidtothereservoiruntilitreachesthecold

levelofthebafe.

7.Runthemachineatlowidlefor15minutestoallow

anyairtopurgeoutofthesystemandwarmuid.

RefertoStartingandStoppingtheEngine.

8.Rechecktheuidlevelwhiletheuidiswarm.If

required,adduidtothereservoiruntilitreaches

thehotlevelofthebafe.

Note:Theuidlevelshouldbetothetopofthehot

levelofthebafe,whentheuidiswarm(

Figure59).

9.Installcaponllerneck.

42

Loading...

Loading...