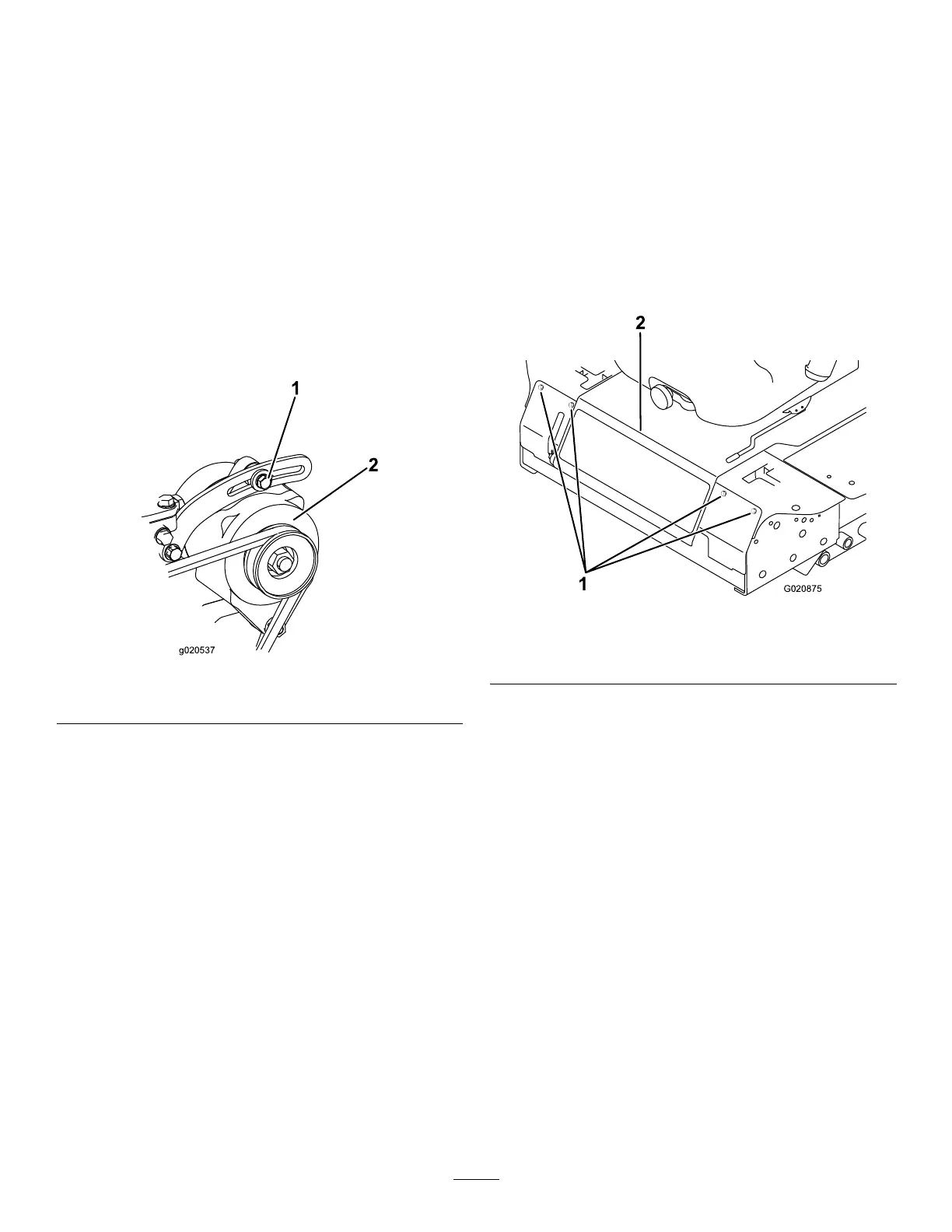

BeltMaintenance

CheckingtheAlternatorBelt

ServiceInterval:Every100hours

Checktheconditionandtensionofthebelts(Figure43)after

every100operatinghours.

1.Propertensionwillallow10mm(3/8inch)deection

whenaforceof44N(10lb.)isappliedonthebelt

midwaybetweenthepulleys.

2.Ifthedeectionisnot10mm(3/8inch),loosenthe

alternatormountingbolts(Figure43).Increaseor

decreasethealternatorbelttensionandtightenthe

bolts.Checkthedeectionofthebeltagaintoensure

thatthetensioniscorrect.

Figure43

1.Mountingbolt2.Alternator

ControlsSystem

Maintenance

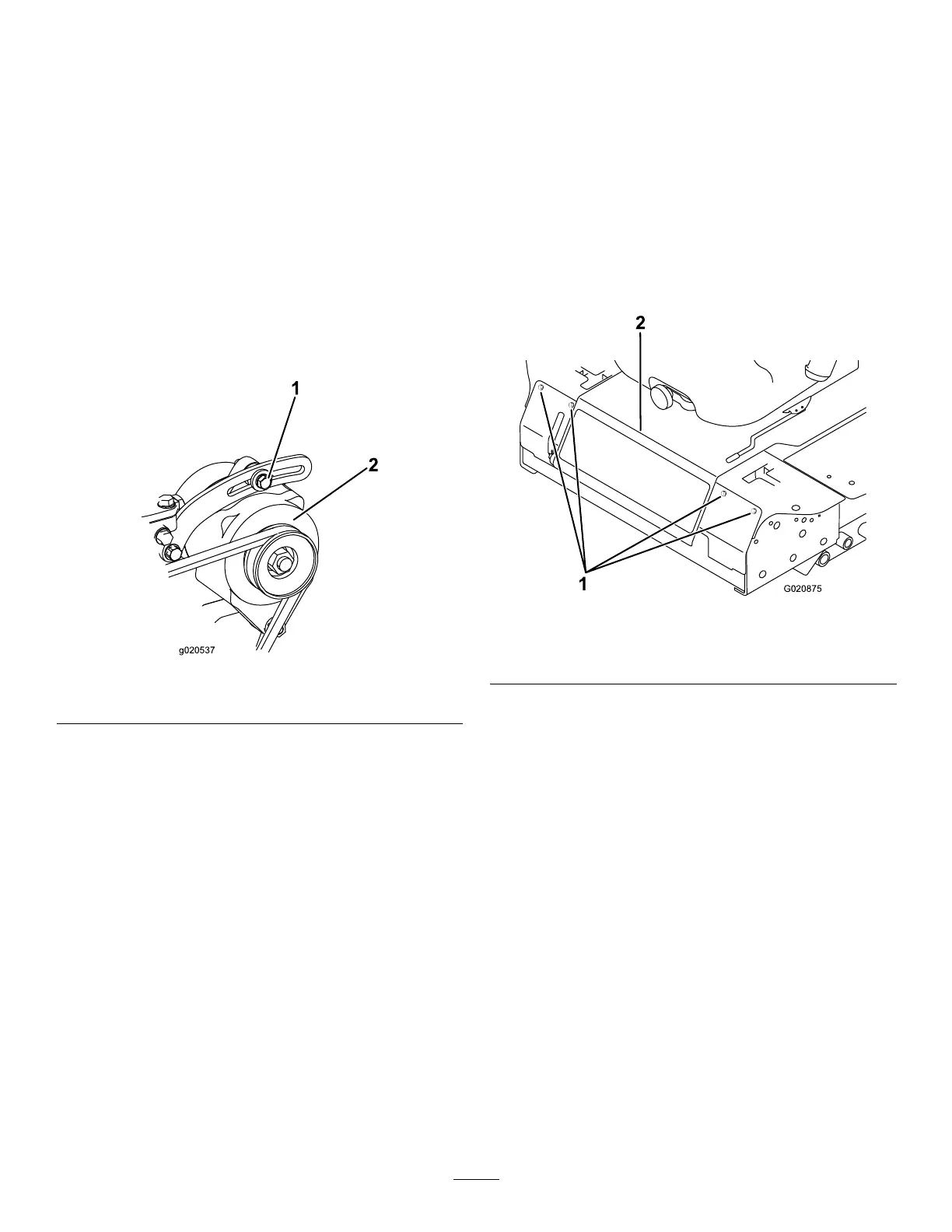

AdjustingtheControlLever

NeutralInterlockSwitch

1.Stopthemachine,movethedeckliftswitchfullyinto

theneutral-lockedposition,settheparkingbrake,and

removetheignitionkey.

2.Removetheboltssecuringthefrontpanelandremove

thepanel(Figure44).

Figure44

1.Bolts

2.Controlpanel

3.Loosenthe2screwssecuringtheinterlockswitch

(Figure45).

42

Loading...

Loading...