Figure48

1.Neutralposition2.Neutrallockedposition

7.Ifadjustmentisneeded,loosenthenutandjamnut

againsttheyoke(Figure47).

8.Applyingslightrearwardpressureonthemotion

controllever,turntheheadoftheadjustmentbolt

intheappropriatedirectionuntilthecontrolleveris

centeredintheneutrallockposition(Figure47).

Note:Keepingrearwardpressureontheleverwill

keepthepinattheendoftheslotandallowthe

adjustmentbolttomovethelevertotheappropriate

position.

9.Tightenthenutandjamnut(Figure47).

10.Repeatsteps4through9fortheothercontrollever.

11.Installthefrontpanel.

AdjustingtheTractionDrive

forNeutral

Thisadjustmentmustbemadewithdrivewheelsturning.

DANGER

Mechanicalorhydraulicjacksmayfailtosupport

themachineandcauseaseriousinjury.

•Usejackstandswhensupportingthemachine.

•Donotusehydraulicjacks.

WARNING

Theenginemustberunningtoperformthis

adjustment.Contactwithmovingpartsorhot

surfacesmaycausepersonalinjury.

Keephands,feet,face,clothing,andotherbody

partsawayfromrotatingparts,mufer,andother

hotsurfaces.

1.Raisetheframeontostablejackstandssothatthedrive

wheelscanrotatefreely.

2.Slideseatforward,unlatchit,andswingitupand

forward.

3.Disconnecttheelectricalconnectorfromtheseat

safetyswitch.

4.Temporarilyinstallajumperwireacrossterminalsin

thewiringharnessconnector.

5.Starttheengine,ensurethatthethrottleleverismidway

betweentheFastandSlowpositions,andreleasethe

parkingbrake.

Note:Themotioncontrolleversmustbeinthe

neutrallockedpositionwhilemakinganyadjustments.

6.Adjustthepumprodlengthononesidebyrotating

thehexshaft,intheappropriatedirection,untilthe

correspondingwheelisstillorslightlycreepingin

reverse(Figure49).

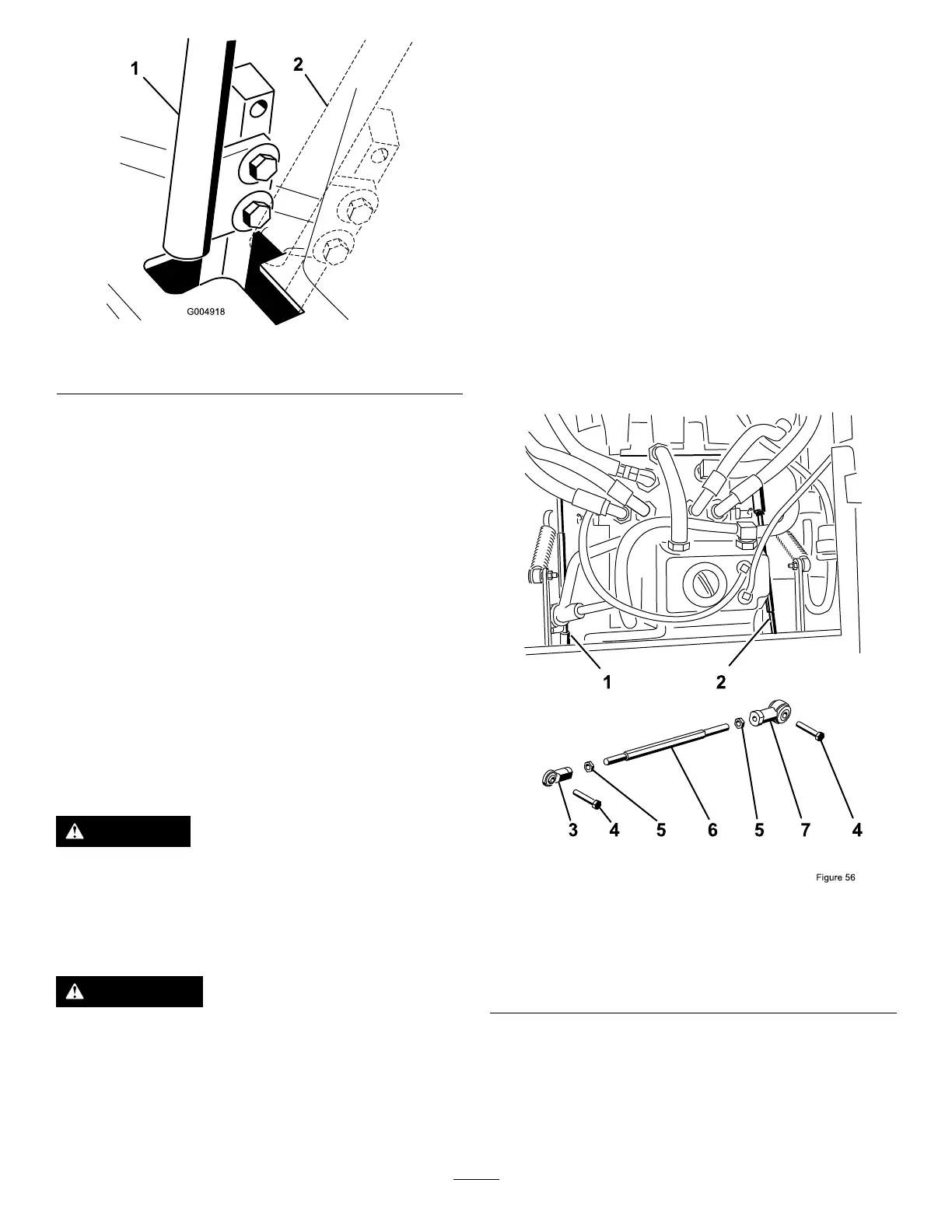

Figure49

1.Rightpumprod5.JamNut

2.Leftpumprod6.Hexshaft

3.Balljoint7.Balljoint

4.Bolt

7.Movethemotioncontrolleverforwardandreverse,

thenbacktoneutral.Thewheelmuststopturningor

slightlycreepinreverse.

8.MovethethrottlelevertotheFastposition.Makesure

thatthewheelremainsstoppedorslightlycreepsin

reverse;adjustitifnecessary.

44

Loading...

Loading...