g036709

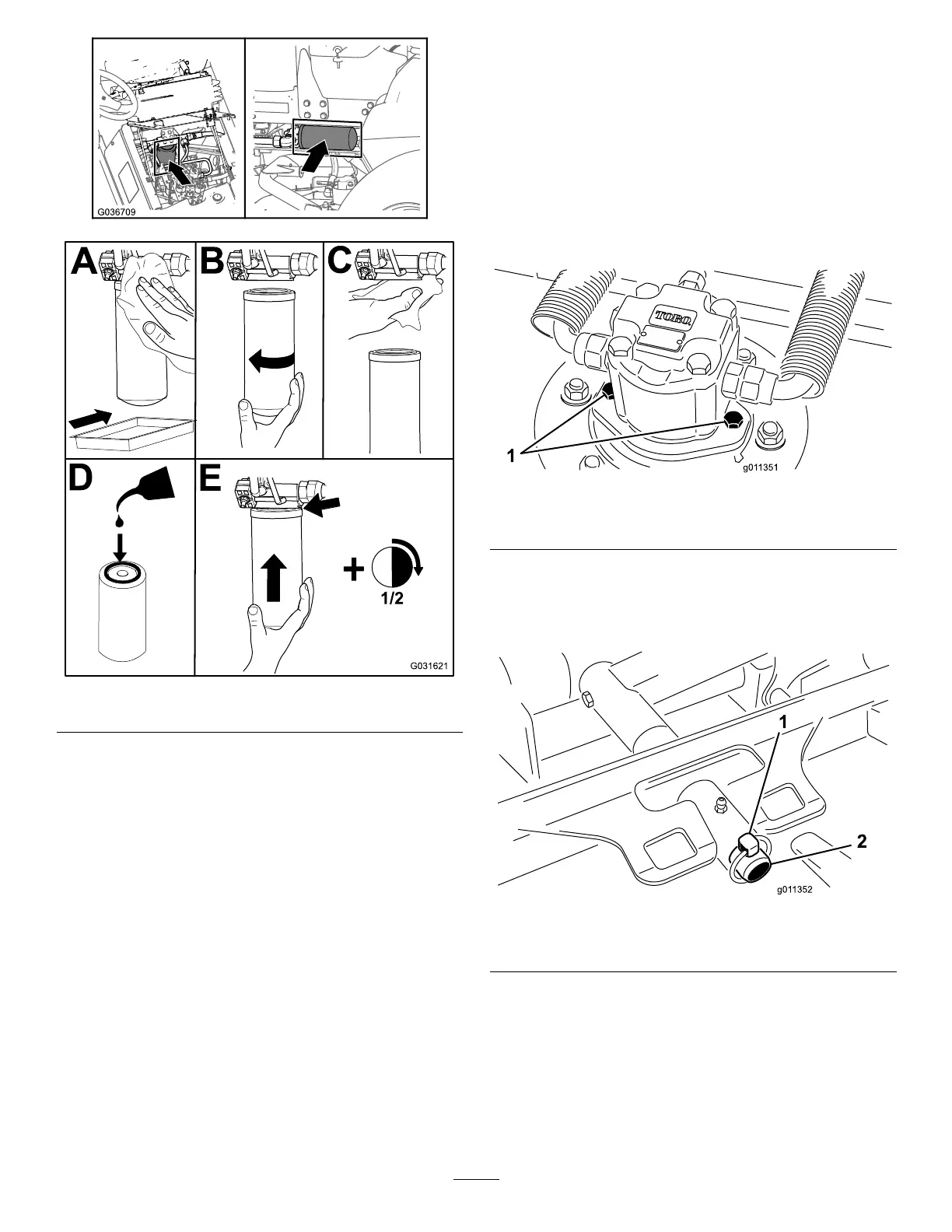

g031621

Figure118

3.Lowerandsecuretheoperator’sseat.

4.Replacethereturnlterattherightsideofthe

machine(Figure118).

5.Starttheengineandletitrunforabout2minutes

topurgeairfromthesystem.Shutofftheengine

andcheckforleaks.

CheckingtheHydraulic

LinesandHoses

ServiceInterval:Beforeeachuseordaily

Inspectthehydrauliclinesandhosesdailyfor

leaks,kinkedlines,loosemountingsupports,wear,

loosettings,weatherdeterioration,andchemical

deterioration.Makeallnecessaryrepairsbefore

operatingthemachine.

CuttingUnitMaintenance

RemovingtheCuttingUnits

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,lowerthecuttingunits,shutoff

theengine,andremovethekey.

2.Disconnectandremovethehydraulicmotor

fromthecuttingunit(Figure119).Coverthetop

ofthespindletopreventcontamination.

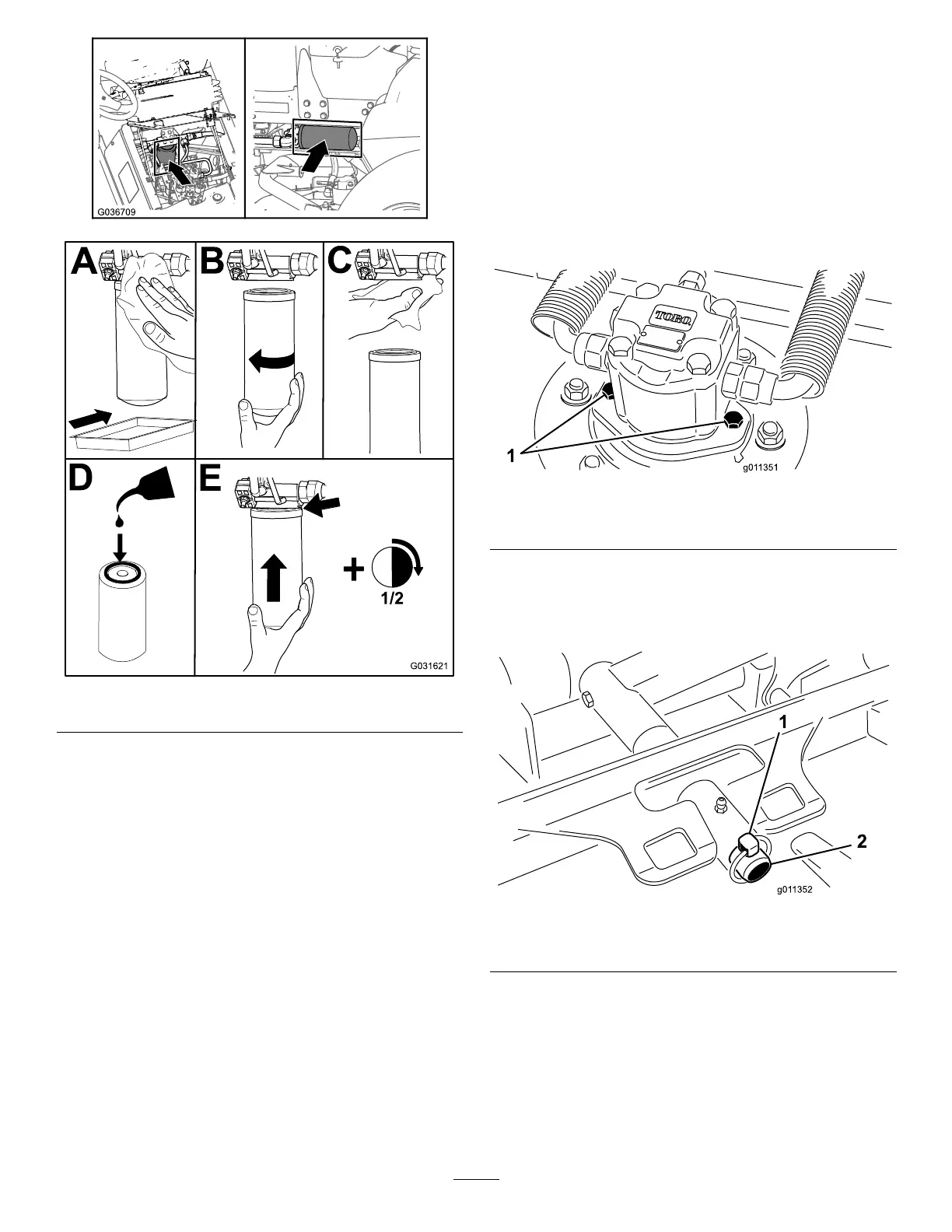

g011351

Figure119

1.Motor-mountingscrews

3.Removethelynchpin(forGroundsmaster4500

machines)orretainingnut(forGroundsmaster

4700machines)securingthecuttingunit-carrier

frametothelift-armpivotpin(Figure120).

g011352

Figure120

1.Lynchpin

2.Lift-armpivotpin

4.Rollthecuttingunitawayfromthemachine.

76

Loading...

Loading...