BladeMaintenance

BladeSafety

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownatyouorbystanders,

resultinginseriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthe

bladesorweargloves,andusecautionwhen

servicingtheblades.Onlyreplaceorsharpenthe

blades;neverstraightenorweldthem.

•Onmulti-bladedmachines,takecareasrotating1

bladecancauseotherbladestorotate.

ServicingtheBladePlane

Thecuttingunitcomesfromthefactorypresetat5

cm(2inches)heightofcutandbladerakeof7.9mm

(0.310inch).Theleftandrightheightsarealsopreset

towithin±0.7mm(0.030inch)oftheother.

Thecuttingunitisdesignedtowithstandblade

impactswithoutdeformationofthechamber.Ifthe

bladestrikesasolidobject,inspectthebladefor

damageandthebladeplaneforaccuracy.

InspectingtheBladePlane

1.Removethehydraulicmotorfromthecuttingunit

andremovethecuttingunitfromthemachine.

2.Useahoist(orminimumof2people)andplace

thecuttingunitonaattable.

3.Mark1endofthebladewithapaintpenor

marker.Usethisendofthebladetocheckall

heights.

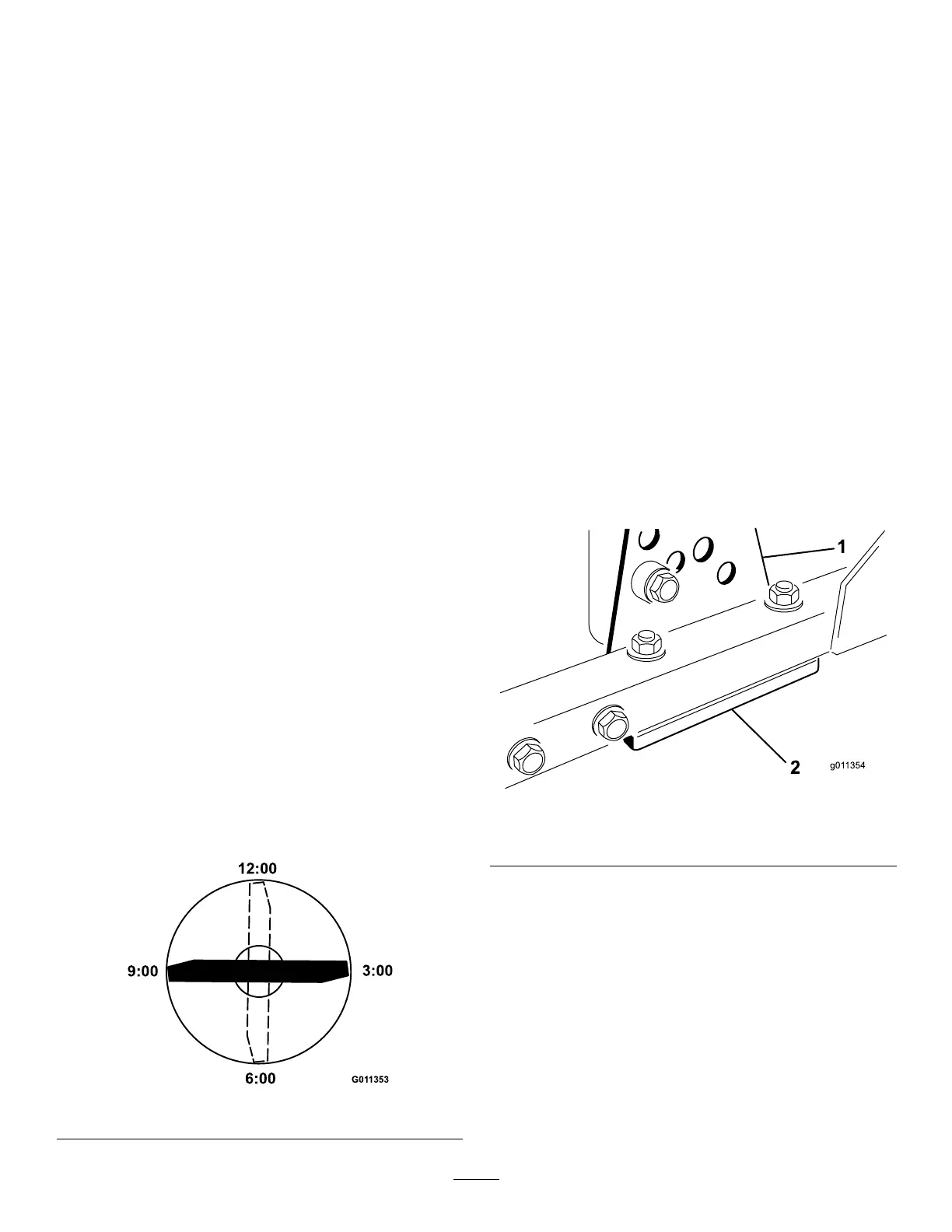

4.Positionthecuttingedgeofthemarkedendof

thebladeat12o’clock(straightaheadinthe

directionofmowing)(Figure122)andmeasure

heightfromtabletocuttingedgeofblade.

g011353

Figure122

5.Rotatethemarkedendofthebladetothe3and

9o’clockpositions(Figure122)andmeasure

theheights.

6.Comparethe12o’clockmeasuredheighttothe

height-of-cutsetting.Itshouldbewithin0.7mm

(0.030inch).The3and9o’clockheightsshould

be1.6to6.0mm(0.060to0.240inch)higher

thanthe12o’clocksettingandwithin2.2mm

(0.090inch)ofeachother.

Ifanyofthesemeasurementsarenotwithin

specication,proceedtoAdjustingtheBladePlane

(page78).

AdjustingtheBladePlane

Startwiththefrontadjustment(change1bracketata

time).

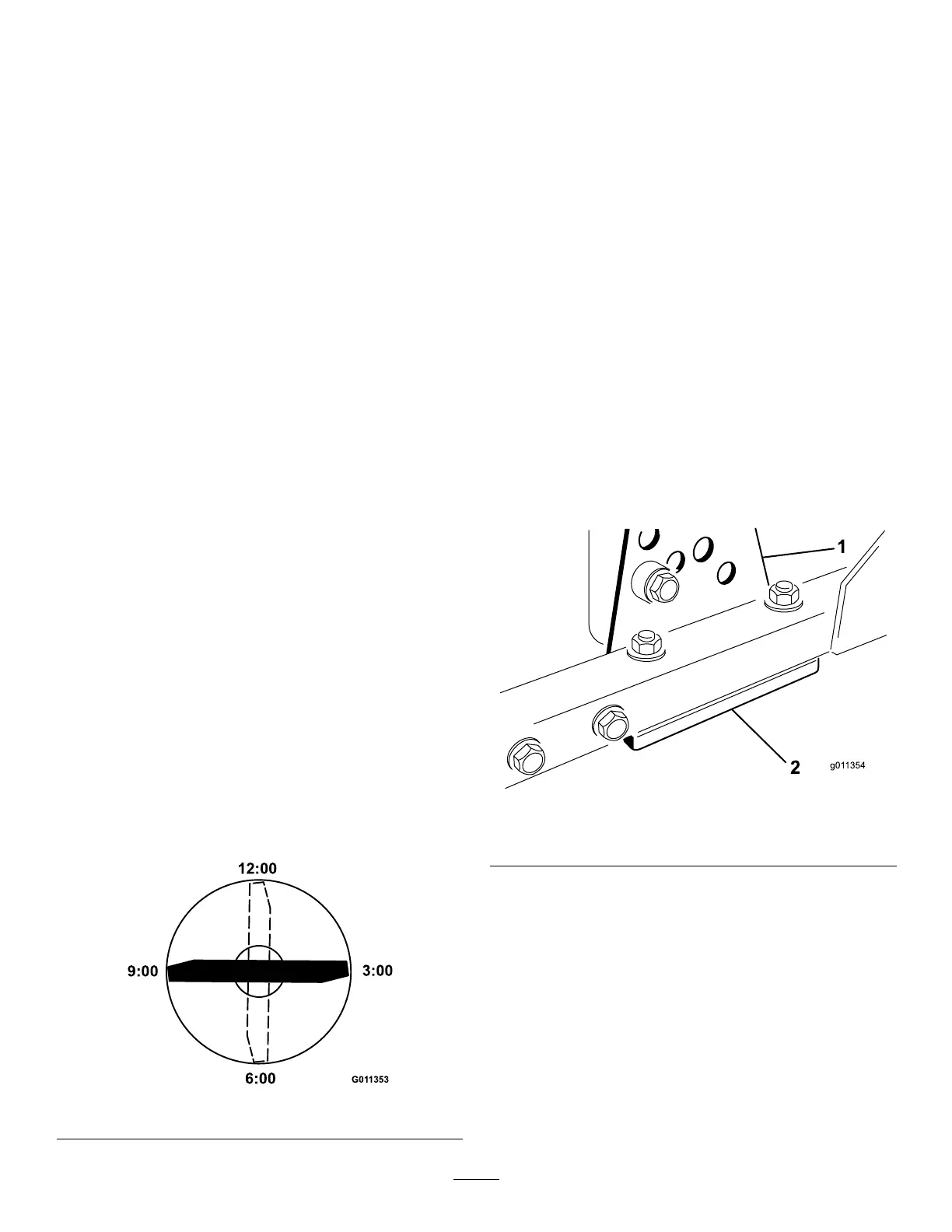

1.Removetheheight-of-cutbracket,(front,left,or

right)fromthecutting-unitframe(Figure123).

2.Adjust1.5mm(0.060inch)shimsand/or0.7

mm(0.030inch)shimsbetweenthecutting-unit

frameandbrackettoachievethedesiredheight

setting(Figure123).

g011354

Figure123

1.Height-of-cutbracket2.Shims

3.Installtheheight-of-cutbrackettothecutting-unit

framewiththeremainingshimsassembled

belowtheheight-of-cutbracket.

4.Securethesocket-headbolt/spacerandange

nut.

Note:Socket-headbolt/spacerareheld

togetherwiththread-lockingadhesivetoprevent

thespacerfromfallinginsidethecutting-unit

frame.

5.Verifythe12o’clockheightandadjustifneeded.

6.Determineifonly1orboth(rightandleft)

height-of-cutbracketsneedtobeadjusted.

78

Loading...

Loading...