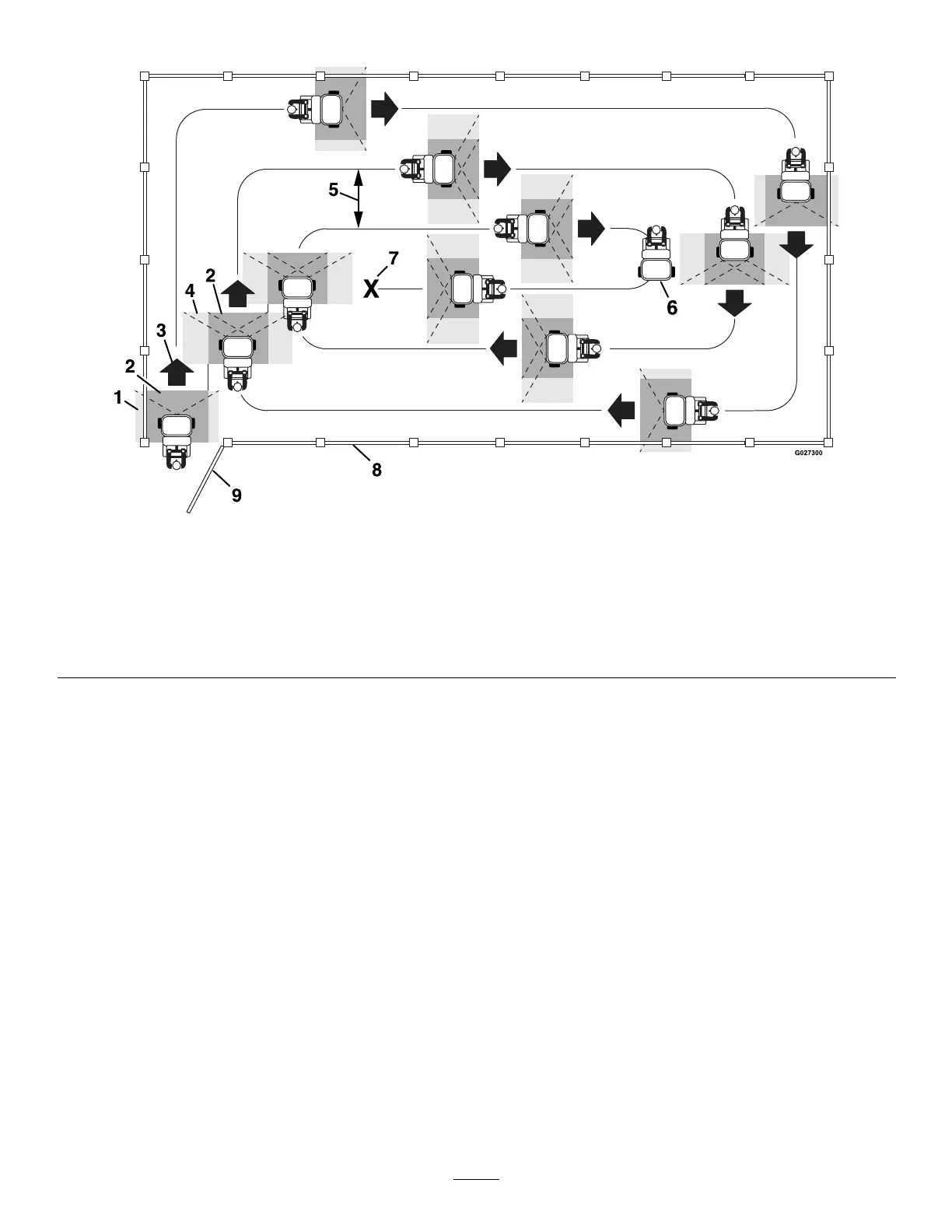

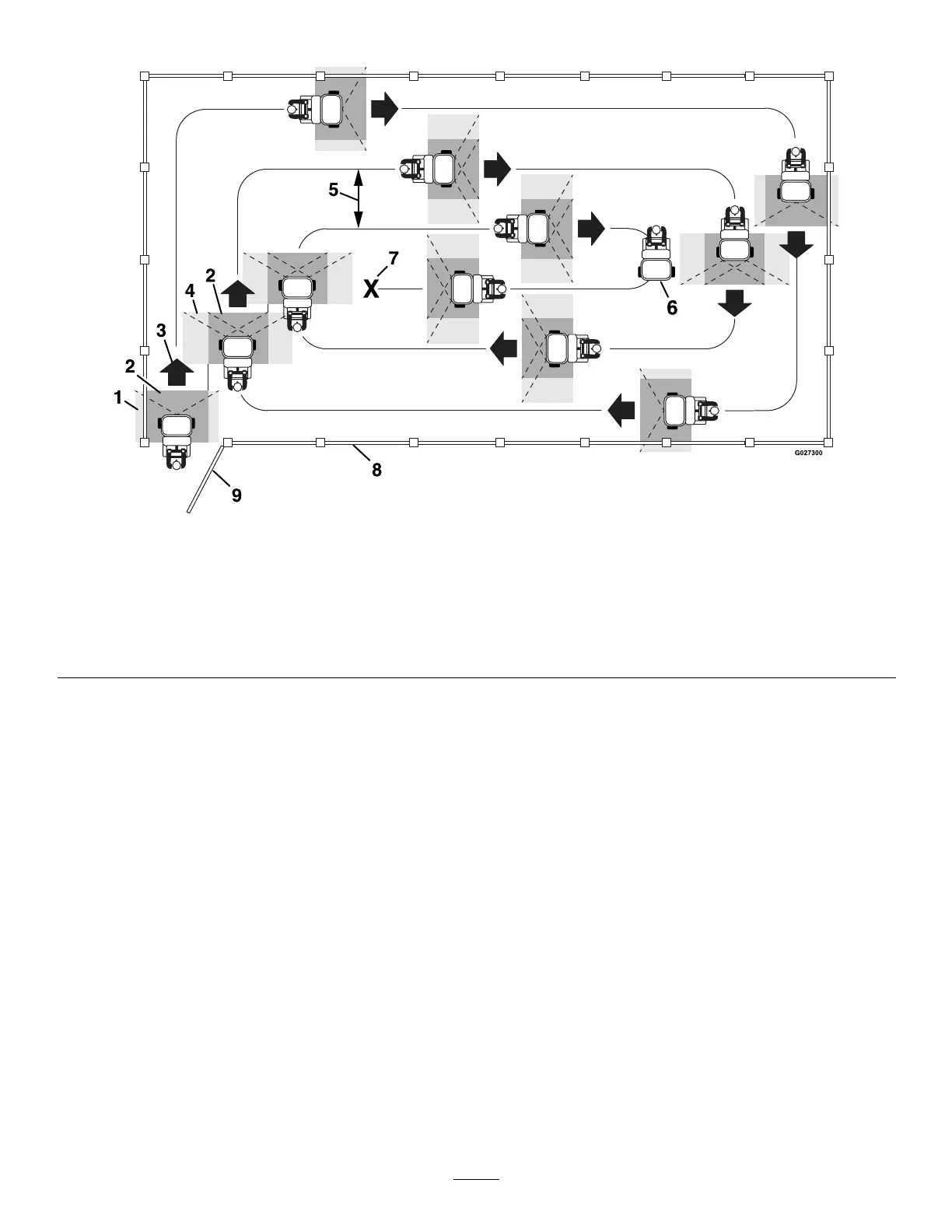

SprayingTips

g027300

Figure58

1.Overlaparea—narrowspraypattern6.SprayerOff—donotspraywhenturningthemachine180°

2.Effectivesprayarea7.Endofsprayingjob

3.Forward

8.Propertyfence

4.Overlaparea—widespraypattern

9.Gate

5.2.4m(8ft)

•Donotoverlaptheeffectivesprayareathatyou

havepreviouslysprayed(seeFigure58).

•Watchforpluggedsprayernozzles.

•Movethenarrow-andwide-spraypatternlevers

totheOFFpositiontostopthesprayowbefore

stoppingthemotionofthemachine.Once

stopped,leavethemotion-controlleverinNEUTRAL

andleavethesprayer-pumpswitchintheON

position.

•Youobtainbetterresultsifthemachineismoving

whenspraycontrolsareturnedON.

•Ensureadequatepumppressureforproperspray

distributionbypushthetank-agitationlevertothe

OFFposition.

•Watchforchangesintheapplicationrate.

Changesintheapplicationrateindicatethatyour

groundspeedhaschangedbeyondtheoperating

rangeofthenozzlesorthereisaproblemwiththe

sprayersystem.

Note:Whenthetankisnearlyempty,thetank

agitationmaycausefoamingofthechemicalsolution

inthetank.Inthiscase,pushthetank-agitationlever

totheOFFposition.Alternatively,ifananti-foaming

agentcompatiblewiththeexistingchemical—addthe

anti-foamingagentaccordingtothemanufacturer’s

instructions.

48

Loading...

Loading...