ServicingtheTransaxle

ServiceInterval:Every50hours

TransaxleOilType:T oro®HYPR-OIL™500

hydraulicoilorMobil®115W-50

1.Preparethemachineformaintenance;referto

PreparingtheMachine(page57).

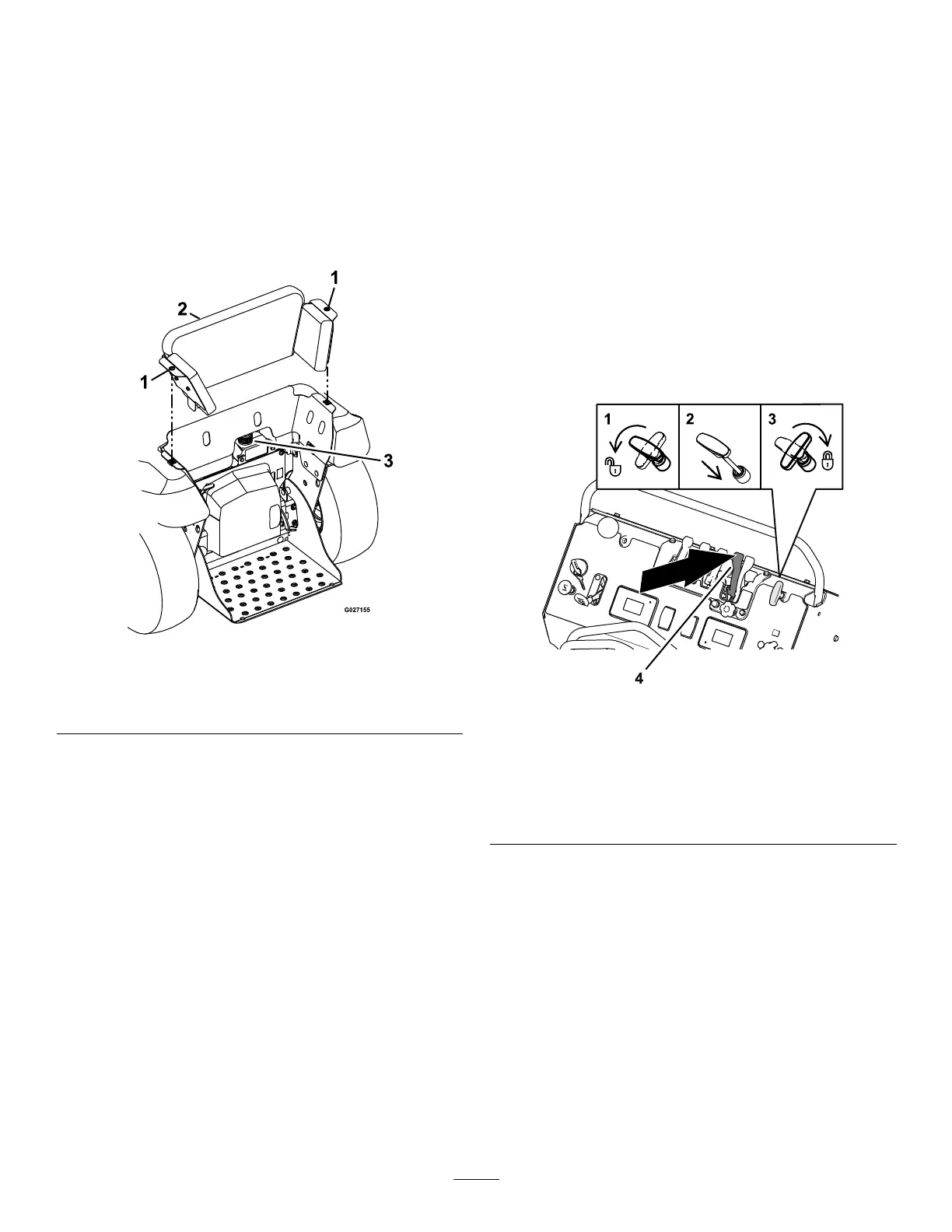

2.Rotatecounterclockwisethe2quarter-turn

fastenersthatsecurethekneepadtothe

chassisofthemachine(Figure97).

g027155

Figure97

1.Quickreleasescrews3.Oilexpansiontank

2.Kneepad

3.Liftthekneepadupandrearwardslightlyand

removethepadfromthemachine(Figure97).

4.Cleanareaarounduid-expansiontankand

removecap(Figure97).

5.Checktheuidlevelintheexpansiontank.

Note:Theuid-levelcoverthebottomportin

tank.

6.Iftheuidlevelistoolow,addthespecieduid

intotheexpansiontank.

7.Installthetankcapontotheexpansiontankand

tightenthecapuntilitissnug(Figure97).

Note:Donotovertightenthecap.

ControlsSystem

Maintenance

AdjustingthePattern

ControlCableforthe

Spreader

1.Preparethemachineformaintenance;referto

PreparingtheMachine(page57).

2.Emptythehopper;refertoEmptyingthe

Spreader(page30).

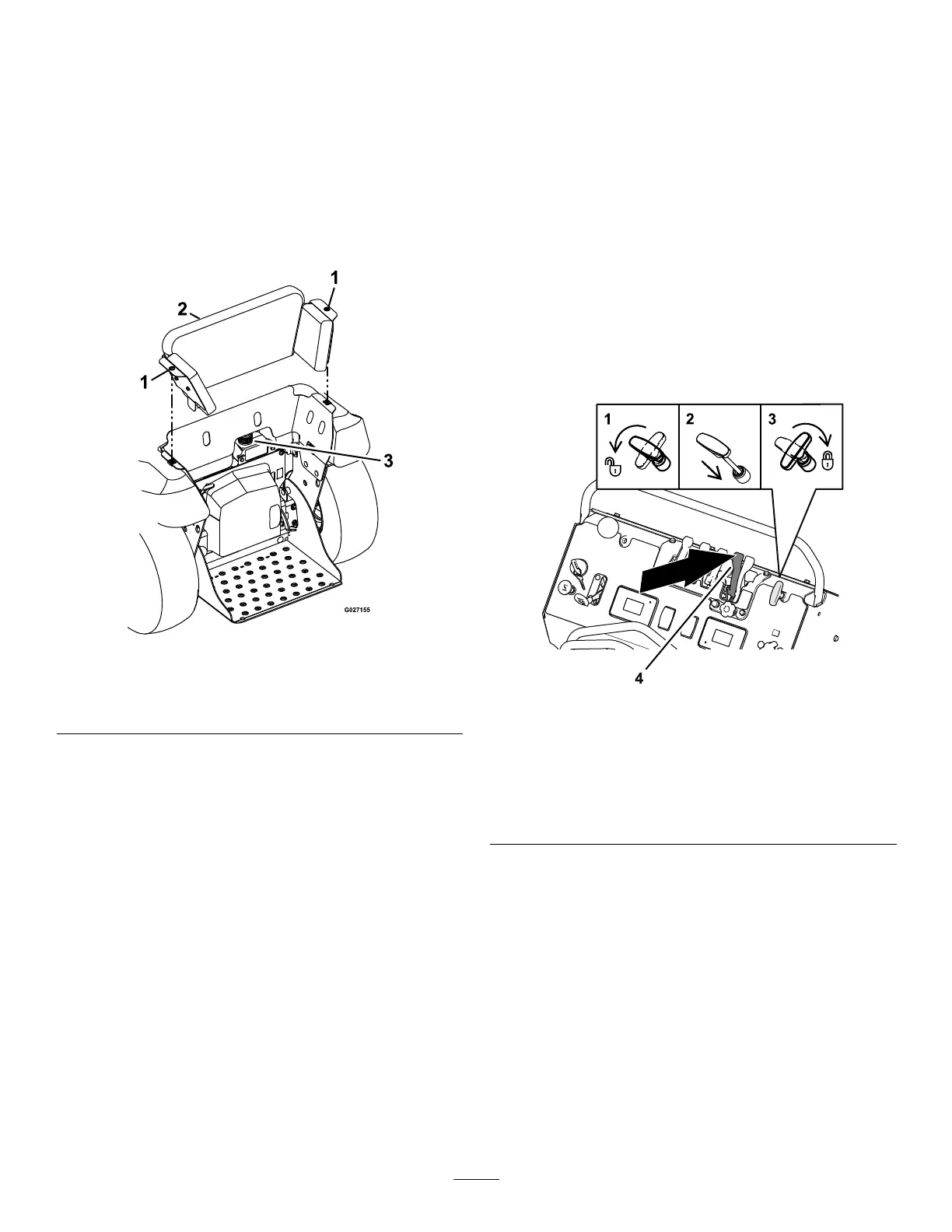

3.Closetheimpellergatebypushingtheheavy

distributiongranular-gateleverforwardfully

(Figure98).

g305495

Figure98

1.Unlock—spreadpattern

controlhandle(rotate

counterclockwise)

3.Lock—spreadpattern

controlhandle(rotate

clockwise)

2.Pushdown—spread

patterncontrolhandle

4.Pushforward—heavy

distributiongranular-gate

lever

4.Rotatethespread-pattern-controlhandle

counterclockwise,pushthehandledown,

androtatethespread-pattern-controlhandle

clockwise(3)refertoFigure98.

5.Loosenthejamnutattheendofthe

pattern-controlcable(Figure99).

70

Loading...

Loading...