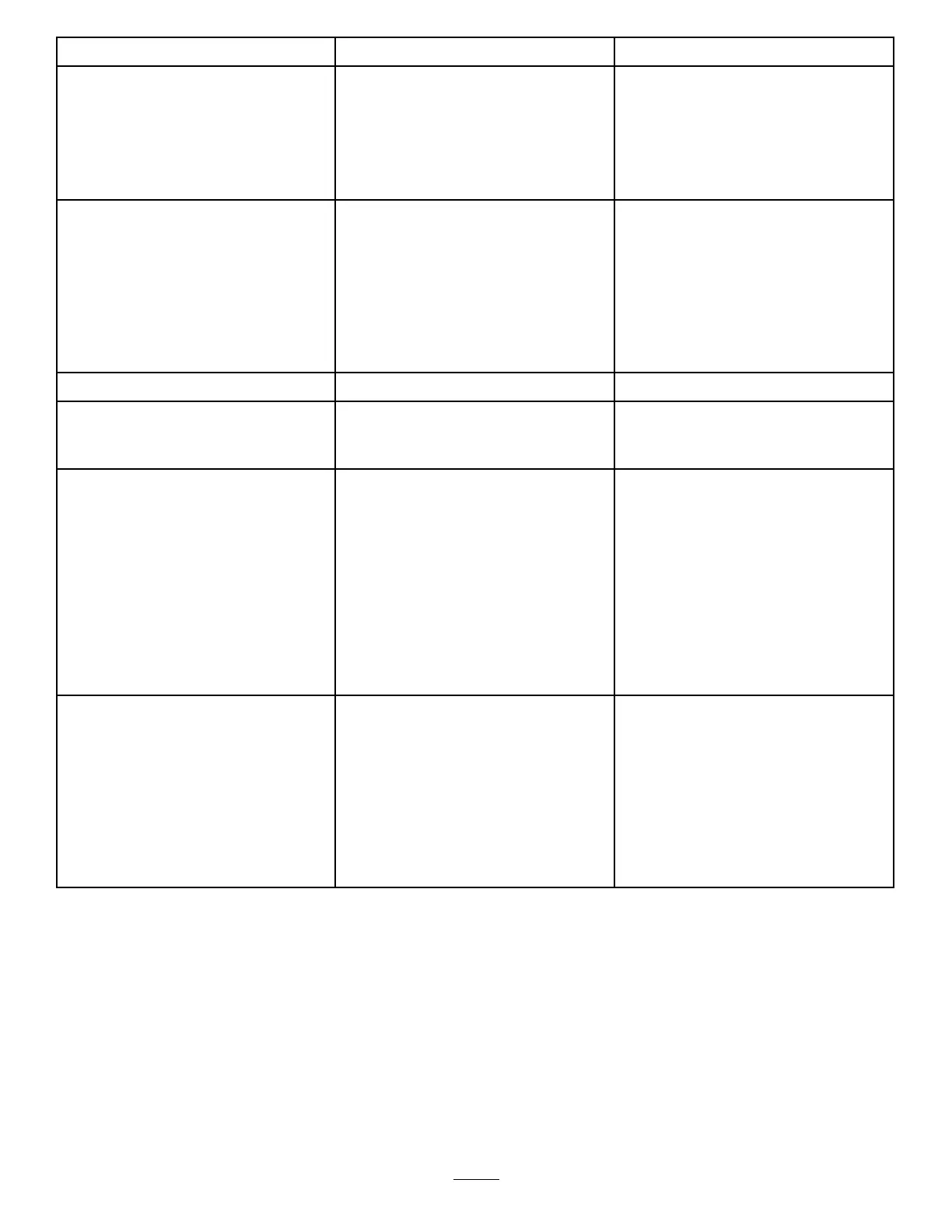

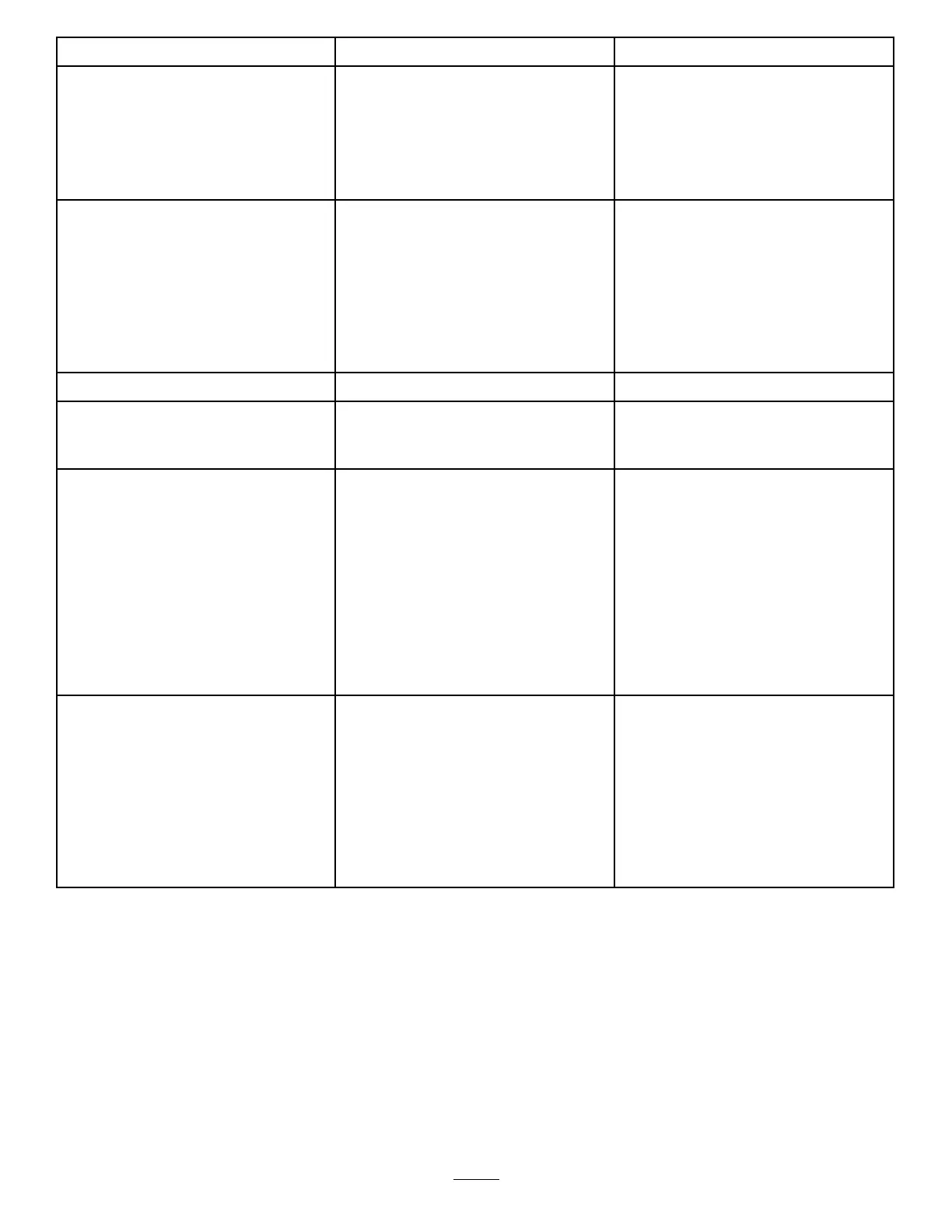

Problem

PossibleCauseCorrectiveAction

1.Theengineloadisexcessive.

1.Reducethegroundspeedofthe

machine.

2.Theoillevelintheengineislow.2.Addoilintotheenginetotheproper

oillevel.

Theengineoverheats.

3.Thecoolingnsandairpassagesfor

theenginearepluggedwithdirtor

debris.

3.Cleanthecoolingnsandtheair

passages.

1.Theairpressureinthetiresisnot

correct.

1.Adjustairpressureinthedrivetires.

2.Thesteeringlinkageisdamaged.2.Replacesteeringlinkage.

3.Thefrontwheeltoe-outisnotcorrect.3.Alignthefrontwheels;refertoAligning

theFrontWheelsprocedure.

4.Thefrontwheelaxlesarebentor

damaged.

4.Repairorreplacethefrontwheelaxles.

Themachinepullstotheleftortheright

(withsteeringcontrolfullyforward).

5.Thesteeringcontrolisbentor

damaged.

5.Repairorreplacethesteeringcontrol.

Themachinedoesnotdrive.1.Thebypassvalveisnotclosedtight.

1.Closethebypassvalve.

1.Theengine-mountingboltsareloose.1.Tightentheengine-mountingbolts. Themachinevibratesabnormally.

2.Thecouplingboltsandnutsforthe

driveshaftareloose.

2.Tightentheappropriatefasteners.

1.Thereisdebrisbuildupattheimpeller.

1.Cleantheimpeller.

2.Thehopperscreenisplugged.

2.Cleanthehopperscreen.

3.Theimpellermotorislooseor

damaged.

3.Repairorreplacetheimpellermotor.

4.Anelectricalcomponentforthe

impellermotorsystemisopen.

4.Checktheelectricalconnections.

5.TheimpellerOn/Offswitchisinthe

OFFpositionortheimpellerspeed

controlissettooslow.

5.SettheimpellerOn/Offswitchtothe

ONpositionandcheckthepositionof

theknobfortheimpeller-speedcontrol.

6.Theimpeller-drivepinismissing.6.Replacethedrivepin.

Theimpellerdoesnotrotate.

7.Thebearingsfailedintheimpeller

motor.

7.Replacethebearingsinthemotoror

themotorassembly.

1.Theimpellerisdirtyordamaged.

1.Clean,repair,orreplacetheimpeller.

2.Thespreader-patterncontrolisnot

adjustedproperly.

2.Adjustthespreader-patterncontrol;

refertotheAdjusttheSpreaderPattern

procedureintheUsingtheSpreader

section.

3.Thesprayernozzlesareclogged.

3.Cleanorreplacethenozzles.

4.Thehopperscreenisplugged.

4.Cleanthehopperscreen.

5.Materialinthehopperisclumpedover

thegate.

5.Checktoseeiftheagitatorpinforthe

shaftoftheimpellermotorispresent.

Thespreaderorsprayerpatternisuneven.

6.Thediffuserrampsettingisincorrect.6.Adjustthepositionofthecontrolcable.

80

Loading...

Loading...