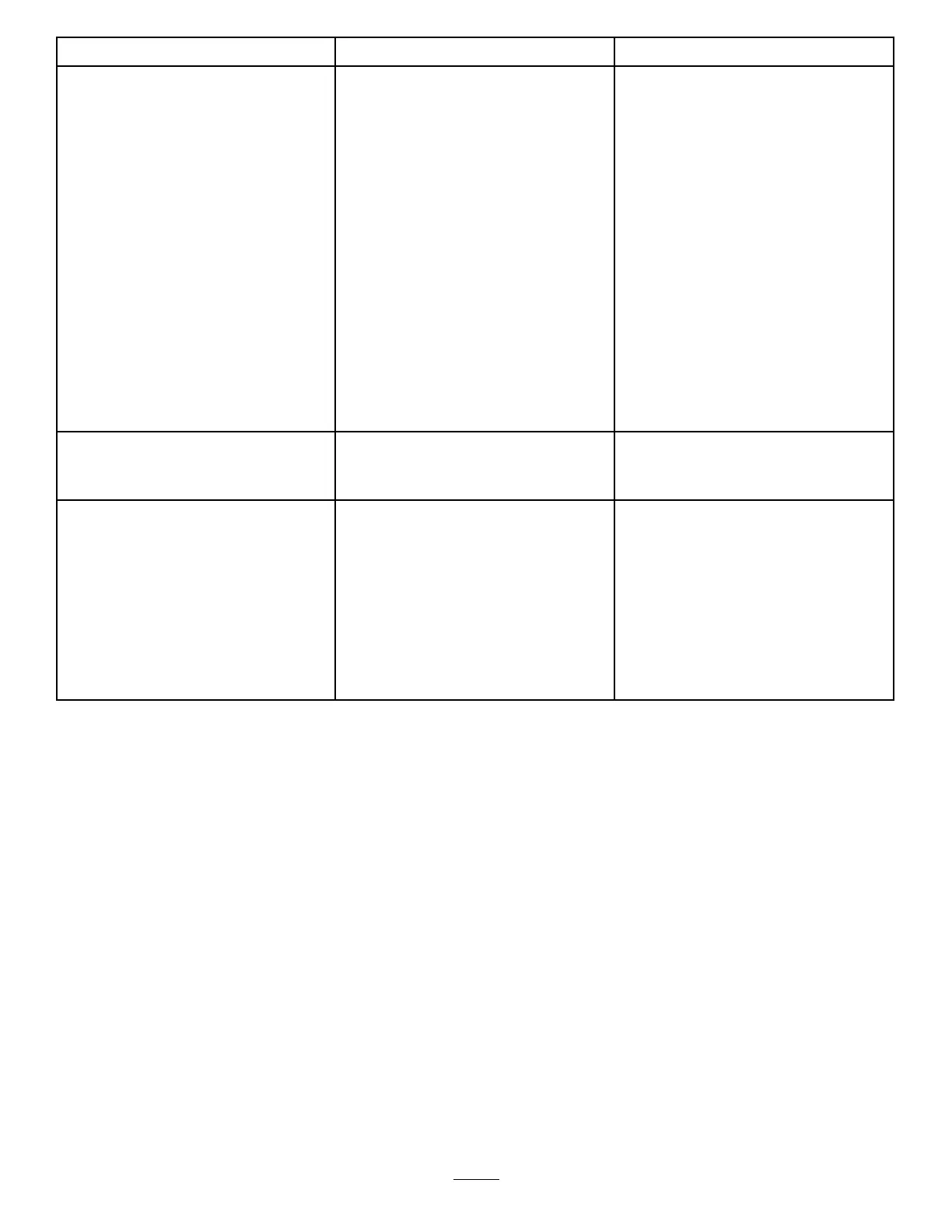

Problem

PossibleCauseCorrectiveAction

1.Thesprayertankisempty.1.Fillthesprayertank.

2.Thesprayer-pumpsupplyvalveis

closedorpartiallyclosed.

2.Fullyopenthesprayer-pumpsupply

valve.

3.Thestraineriscloggedordamaged.

3.Clean,repair,orreplacethestrainer.

4.Thepumpiscloggedordamaged.

4.Clean,repair,orreplacethepump.

5.Thenozzlesareclogged.

5.Cleanorreplacethenozzles.

6.Thehosesareclogged,kinked,or

damaged.

6.Clean,repair,orreplacethehoses.

7.Thetank-agitationleverisintheON

position.

7.Movethetank-agitationlevertothe

OFFposition.

8.Thesprayer-patternleverisnotinthe

ONposition.

8.Movethenarrow-orwide-sprayer

patternlevertotheONposition.

9.Thesprayerpressureandground

speedareincorrect.

9.Adjustthesprayerpressureandthe

groundspeedofthemachine.

10.Thechemicalmixtureinthesprayer

tankisincorrect.

10.Followthechemicalmanufacturer’s

recommendation.

Thereisnosprayfromthesprayernozzles

intheboomorthenozzleshavepoor

output.

11.Thespraysystemisleaking.

11.Inspectthecomponentsofthesprayer

system;clean,repair,orreplace

thesprayer-systemcomponentsas

needed.

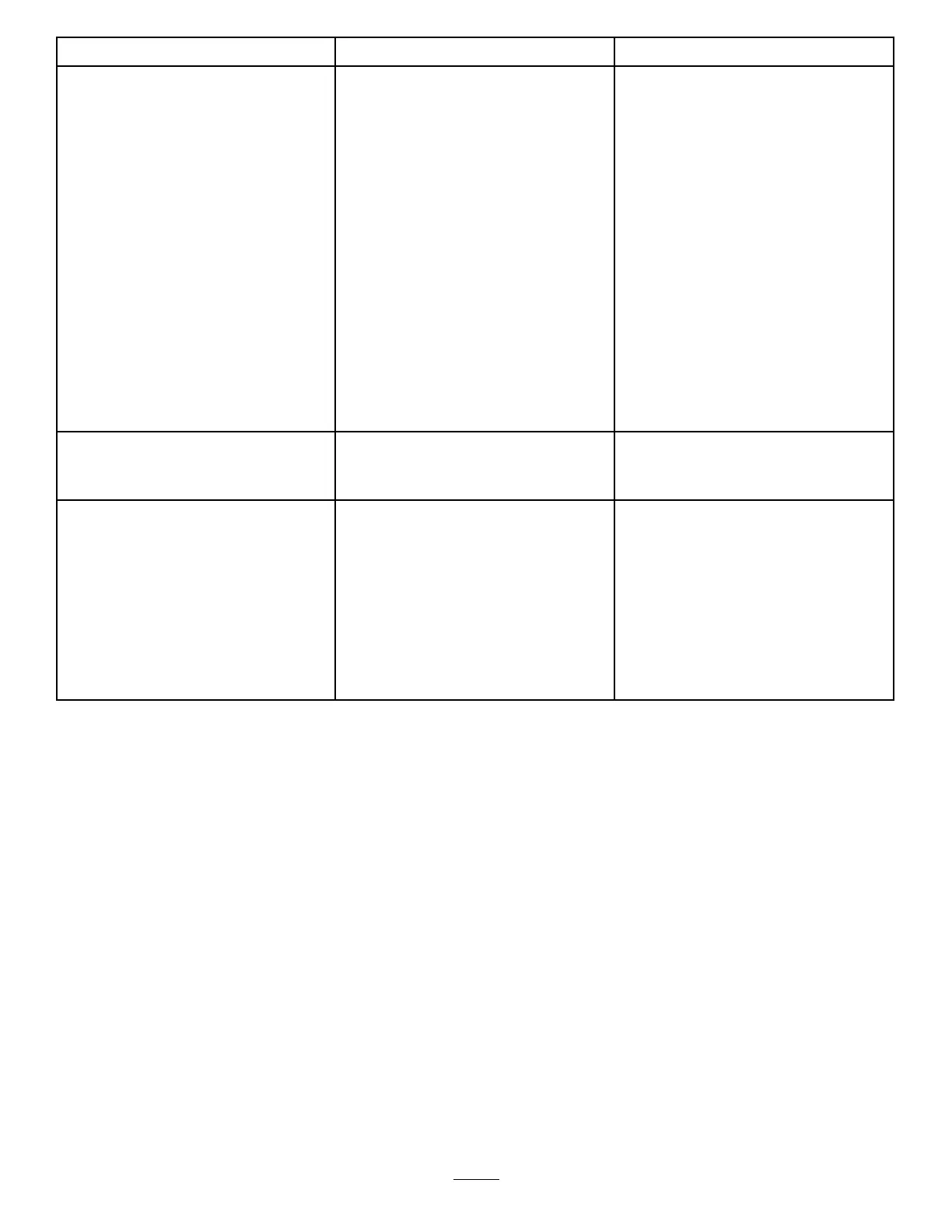

1.Hopperscreenisplugged.

1.Cleanthehopperscreen.

Nomaterialdispensedfromhopper.

2.Gatenotadjustedproperly.2.Adjustthegate.SeeSpreaderPattern

AdjustmentsectioninOperation.

1.Thesprayertankisempty.1.Fillthesprayertank.

2.Thesprayer-wand-pressurecontrolis

inthewrongposition.

2.Rotatethepressurecontroltothe

OPENposition.

3.Thewandiscloggedordamaged.

3.Clean,repair,orreplacethewand.

4.Thespraynozzleforthewandis

clogged.

4.Cleanorreplacethenozzle.

5.Thetriggerisnotpressed.5.Pressthetrigger.

6.Thehoseiscloggedordamaged.

6.Clean,repair,orreplacethehoses.

7.Thehoseisnotconnectedtothewand.

7.Connectthehosetothewand.

Thespraywanddoesnotwork.

8.Thehoseforthewandiskinked.8.Straightenthekinkinthehose.

81

Loading...

Loading...