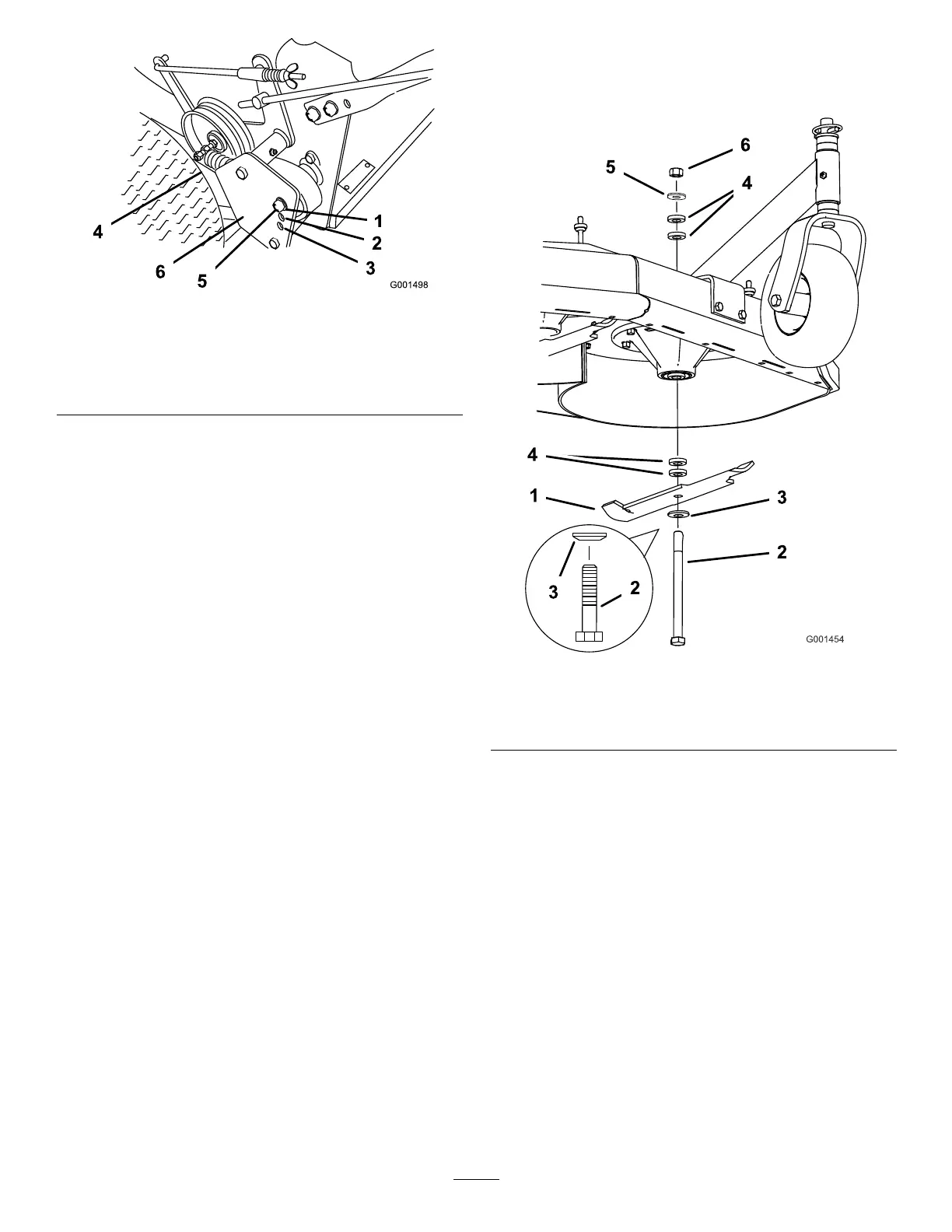

Figure9

1.PositionA4.Drivespring

2.PositionB

5.Adjustmentbolt(In

positionA)

3.PositionC

6.Drivepulleyshield

5.Removethelocknutthatsecurestheadjustment

bolttothedrivepulleyshield(Figure9).

6.Locateboltassemblyinthedesiredtensionposition

asfollows:

•PositionAfornormalconditions

•PositionBformoresevereconditions

•PositionCforthemostsevereconditions

Note:Thewheeldrivetensionislowestwhen

theboltassemblyisinPositionA.Thetension

increasesinPositionsBandC(Figure9).

7.Installtheadjustmentboltandthedrivespring.

8.Repeatstepsthroughfortheoppositeside.

AdjustingtheHeight-of-Cut

Thismachinehasa1to4-1/4inch(26to108mm)

rangefortheheight-of-cut.Thiscanbeachievedby

adjustingbladespacers,rearaxleheight,andfront

casterspacers.UsetheHeight-of-CutCharttoselect

thecombinationofadjustmentsrequired.

AdjustingtheBladeHeight

Adjustthebladesbyusingthe4spacers(1/4inch)

(6mm)onthebladespindlebolts.Thisallowsfora

1-inch(25mm)adjustmentrange,in1/4inch(6mm)

increments,ofcuttingheightinanyaxleposition.Use

thesamenumberofbladespacersonallbladesto

achievealevelcut(2aboveand2below,1aboveand3

below,etc.).

1.Disengagethebladecontrol(PTO)leverandset

theparkingbrakes.

2.Stoptheengineandwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Holdthebladeboltandremovethenut(Figure10).

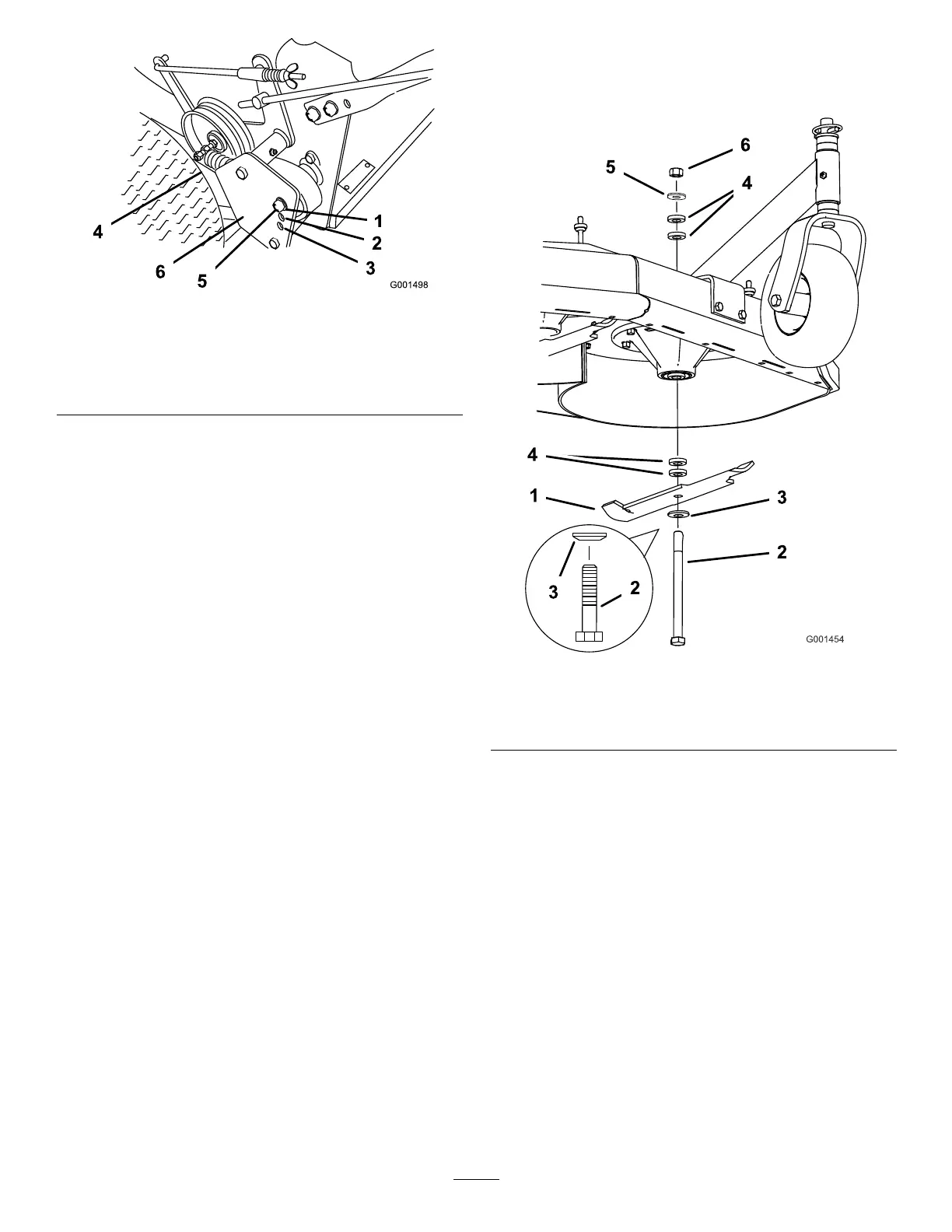

Figure10

1.Blade

4.Spacer

2.Bladebolt5.Thinwasher

3.Curvedwasher

6.Nut

4.Slidetheboltdownthroughthespindle,andchange

thespacersasneeded(Figure10).

5.Installtheboltandcurvedwasher,addextra

spacer(s),andsecurethemwithathinwasheranda

nut(Figure10).

6.Torquethebladeboltto75-80ft-lb(101-108N⋅m).

AdjustingtheAxleHeight

Adjusttheaxlepositiontotheselectedheight-of-cut

setting.RefertotheHeight-of-CutChart.

1.Disengagethebladecontrol(PTO)leverandset

theparkingbrakes.

2.Stoptheengineandwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Loosen,butdonotremove,the2axlepivotbolts

andthe2axleadjustmentbolts(Figure11).

16

Loading...

Loading...