1.Disengagethebladecontrol(PTO)leverandsetthe

parkingbrakes.

2.Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Loosenthelocknutontheturnbuckle(Figure34).

4.Rotatetheturnbuckletowardtherearofthe

mowertoincreasethetensiononthebelt.Rotate

theturnbuckletowardthefrontofthemowerto

decreasethetensiononthebelt(Figure34).

Note:Theeyeboltthreadsonbothendsofthe

turnbuckleshouldbeengagedaminimumof

5/16inch(8mm).

ControlsSystem

Maintenance

AdjustingtheControlRods

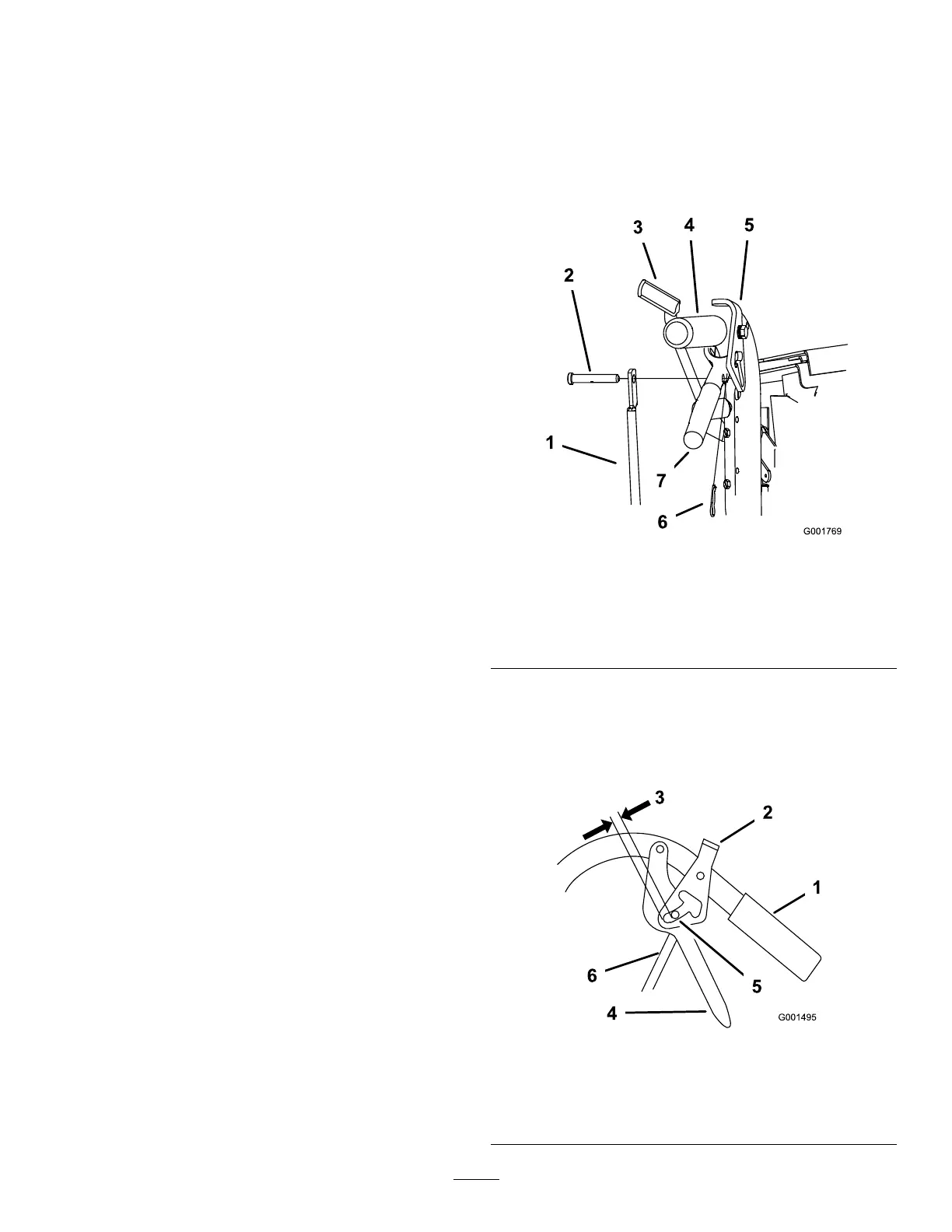

1.Removethehairpincotterpinsandclevispinsfrom

thedriveleversandneutrallocks(Figure35).

Figure35

1.Controlrod

5.Neutrallock

2.Clevispin

6.Hairpincotterpin

3.OperatorPresence

Controllever(OPC)

7.Lefthandleshown

4.Handle8.Drivelever

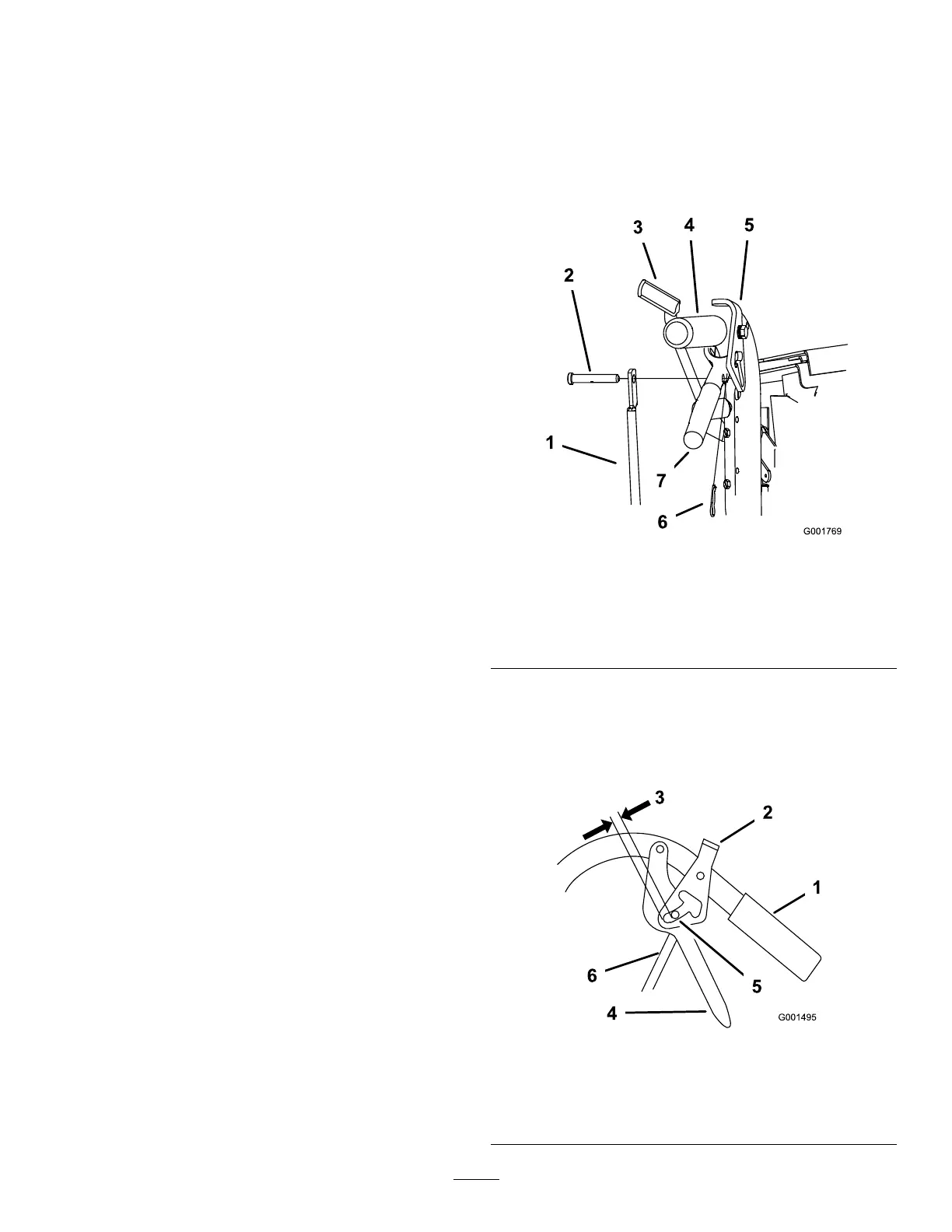

2.Adjustthecontrolrodlengthbythreadingtherodin

oroutoftherodttinguntilthereisa3/16to1/4

inches(5to6mm)clearancebetweenthecontrol

rodandthebottomoftheneutral/parkingbrake

lock(Figure36).

Figure36

1.Handle4.Drivelever

2.Neutral/parkingbrakelock

5.Forwardspeed

3.3/16to1/4inch(5to6

mm)clearance

6.Controlrod

31

Loading...

Loading...