DriveSystem

Maintenance

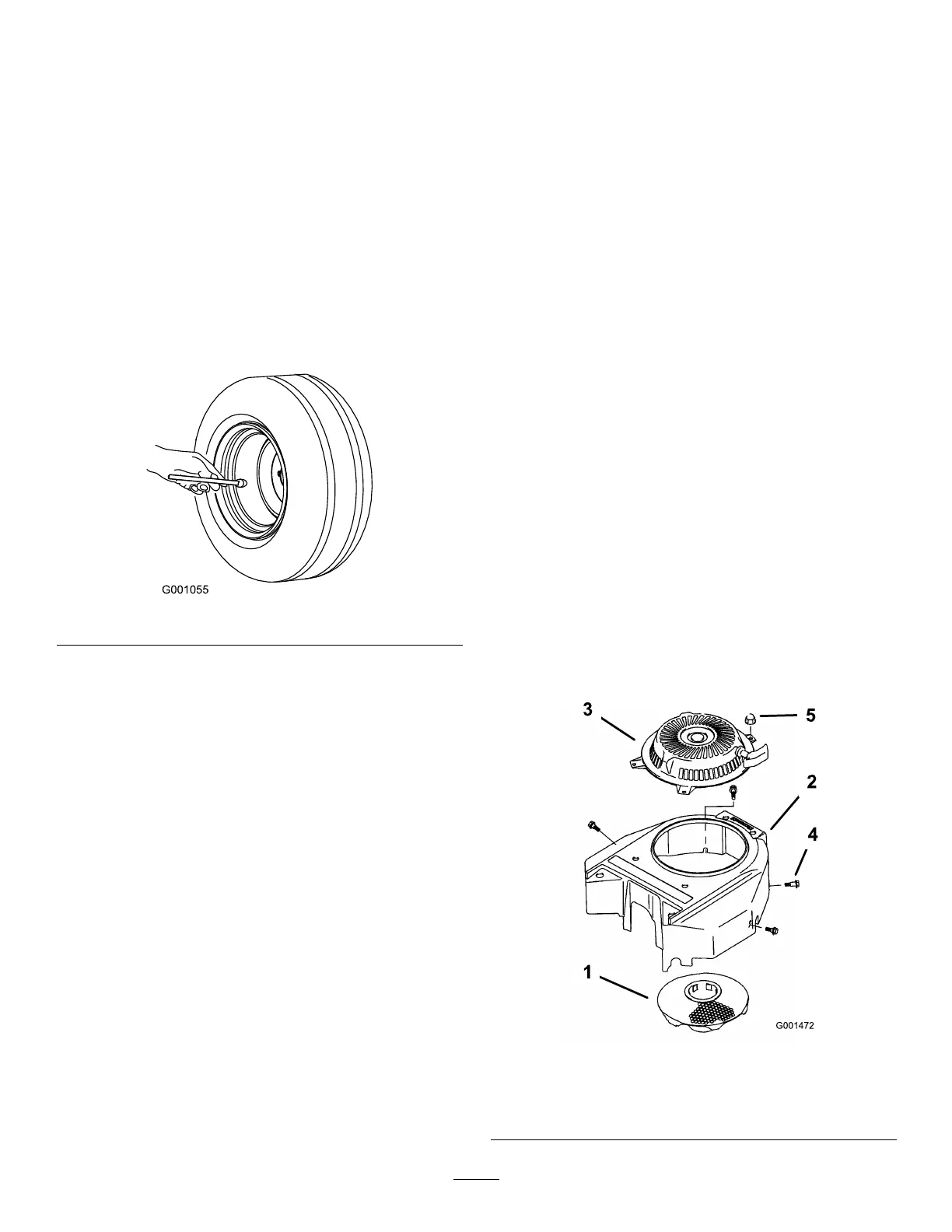

CheckingtheTirePressure

Checkthepressureatthevalvestemafterevery

50operatinghoursormonthly,whicheveroccursrst

(Figure27).

Maintaintheairpressureinthereartiresat12-14psi

(83-97kPa).Uneventirepressurecancauseanuneven

cut.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireairpressuremaintenance.

Figure27

CoolingSystem

Maintenance

CleaningtheAirIntakeScreen

Beforeeachuseremoveanybuild-upofgrass,dirt

orotherdebrisfromthecylinderandcylinderhead

coolingns,airintakescreenonywheelend,and

carburetor-governorleversandlinkage.Thiswillhelp

insureadequatecoolingandcorrectenginespeedand

willreducethepossibilityofoverheatingandmechanical

damagetotheengine.

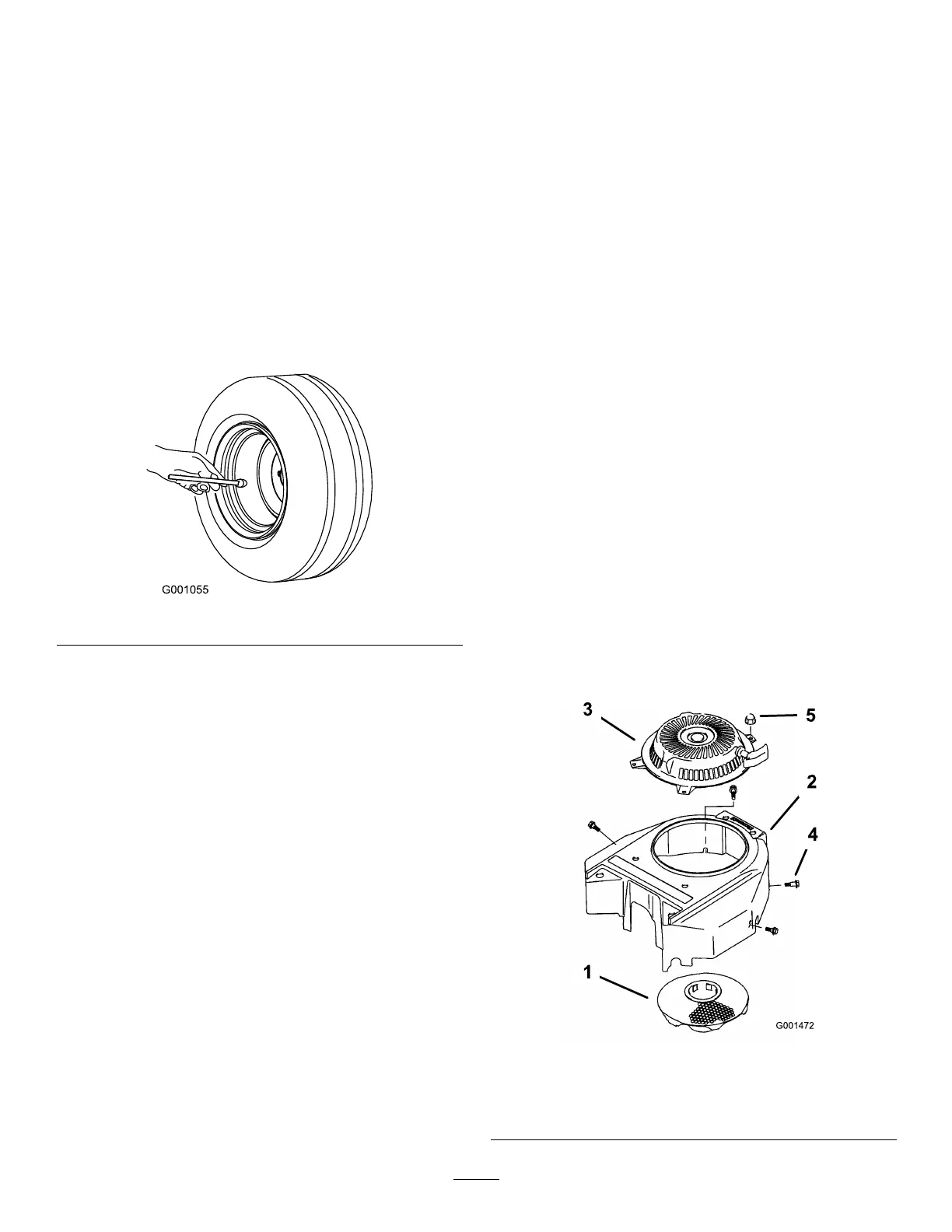

CleaningtheCoolingSystem

Cleantheairintakescreenfromgrassanddebrisbefore

eachuse.

Checkandcleancoolingnsandengineshroudsevery

100hoursoryearly,whichevercomesrst.

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removetheairintakescreen,recoilstarterandfan

housing(Figure28).

4.Cleanthedebrisandgrassfromtheengineparts.

5.Installairintakescreen,recoilstarterandfanhousing

(Figure28).

Figure28

1.Airintakescreen4.Bolt

2.Fanhousing5.Nut

3.Recoilstarter

27

Loading...

Loading...