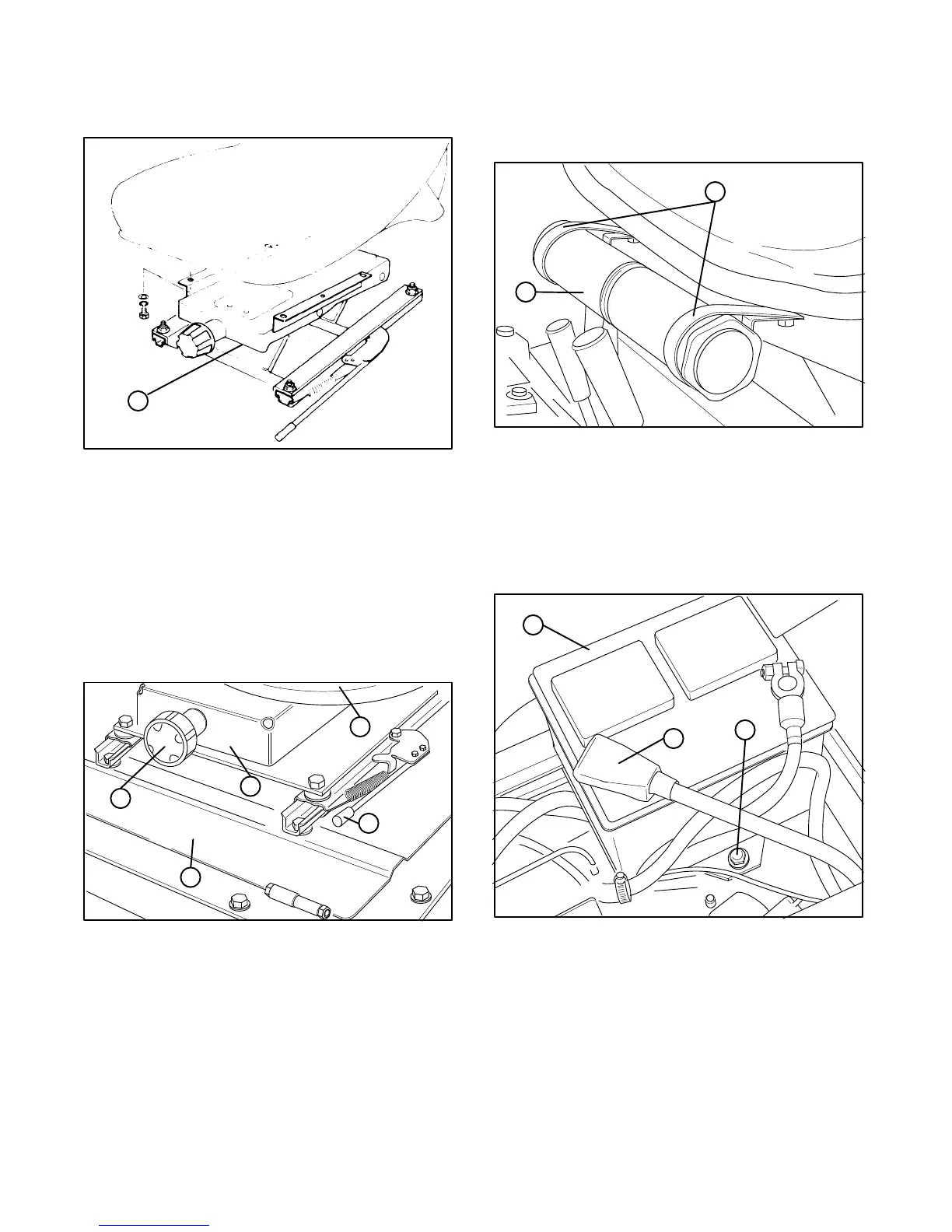

Secure seat suspension to seat mounting plate

with (4) flange locknuts (Fig. 6 & 7).

(&2/%

%!1 020.%,0(-,

Mount seat to seat suspension with (4) capscrews,

lockwashers and flatwashers (Fig. 6 & 7).

Adjust seat for operator's comfort and weight. To

adjust seat fore and aft, pull handle on left side of seat

assembly outward (Fig. 7). Release handle to lock seat

position. To adjust for operator's weight, turn spring

tension knob; clockwise to increase tension,

counterclockwise to decrease spring tension (Fig. 7).

(&2/%

%!1

20.%,0(-, !00%+"*4

-2,1(,& .*!1%

-/3!/$"!#)3!/$ '!,$*%

./(,& 1%,0(-, ),-"

Remove manual tube and R-clamps secured to

seat plate. Retain (2) mounting capscrews and

flatwashers.

Loosely mount R-clamps to outer holes in right

side of seat with (2) capscrews and flatwashers

previously removed. (Fig. 8).

Install manual tube into R-clamps, insert manual

into tube and thread cap into tube (Fig. 2). Tighten

capscrews.

(&2/%

!,2!* 12"%

#*!+.0

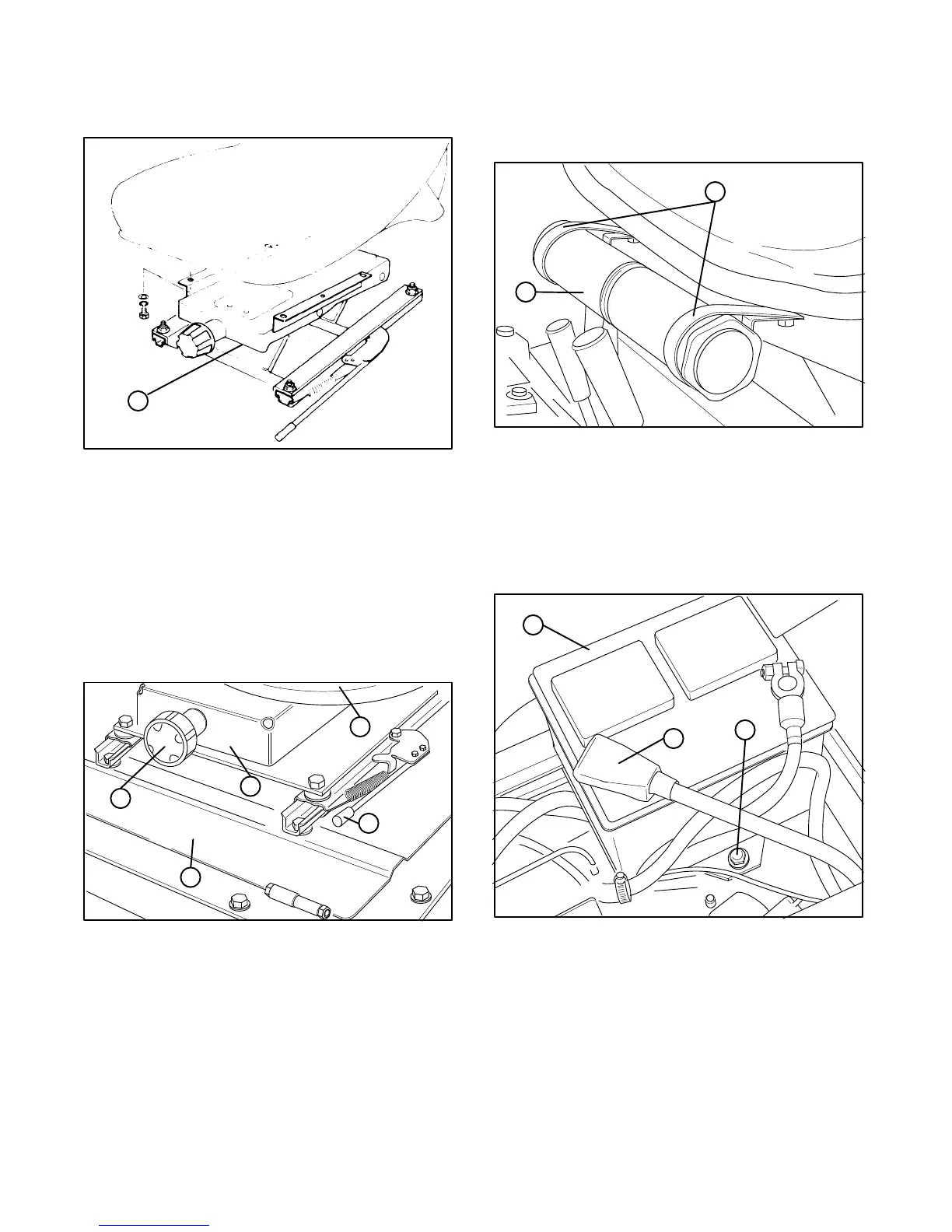

LIft engine cover. Check to see that the battery is

securely fastened in place (Fig. 9).

(&2/%

!11%/4

!11%/4 0%#2/(,& "-*1

2""%/ "--1

Check battery charge with a hydrometer. If battery

needs charging, be sure at least one of the battery

cable is disconnected from the battery before the

charger is connected.

Remove tape from battery cables and secure the

cables to the proper battery post. The positive (+) red

cable goes to the positive post and the negative (-)

black cable goes to the negative post on the battery.

Loading...

Loading...