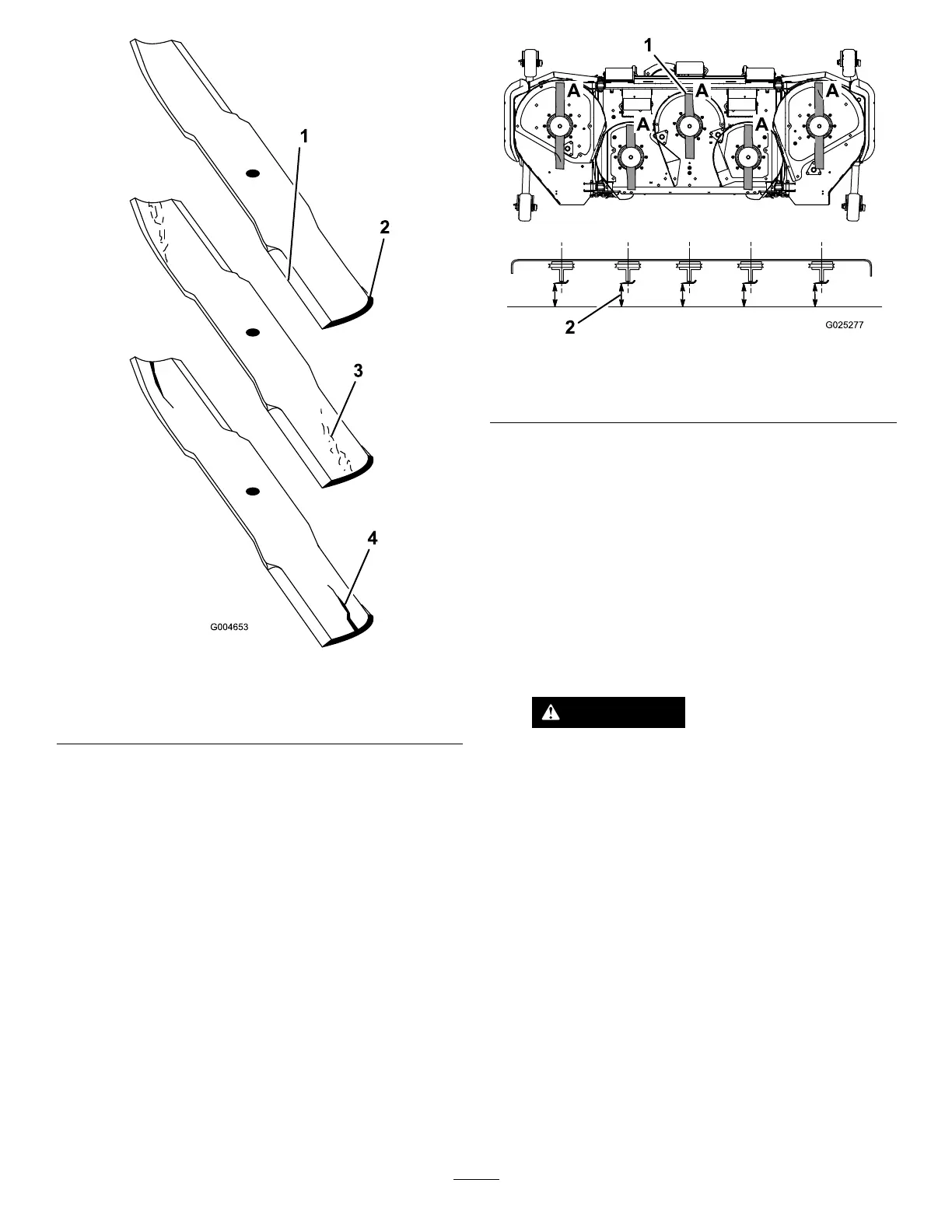

g004653

Figure24

1.Cuttingedge3.Wear/slotforming

2.Sailarea4.Crack

CheckingforBentBlades

1.DisengagethePTO,releasethetractionpedal

andsettheparkingbrake.

2.MovethethrottlelevertotheSlowposition,

stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingthe

operatingposition.

3.Rotatethebladesuntiltheendsfaceforward

andbackward(Figure25).

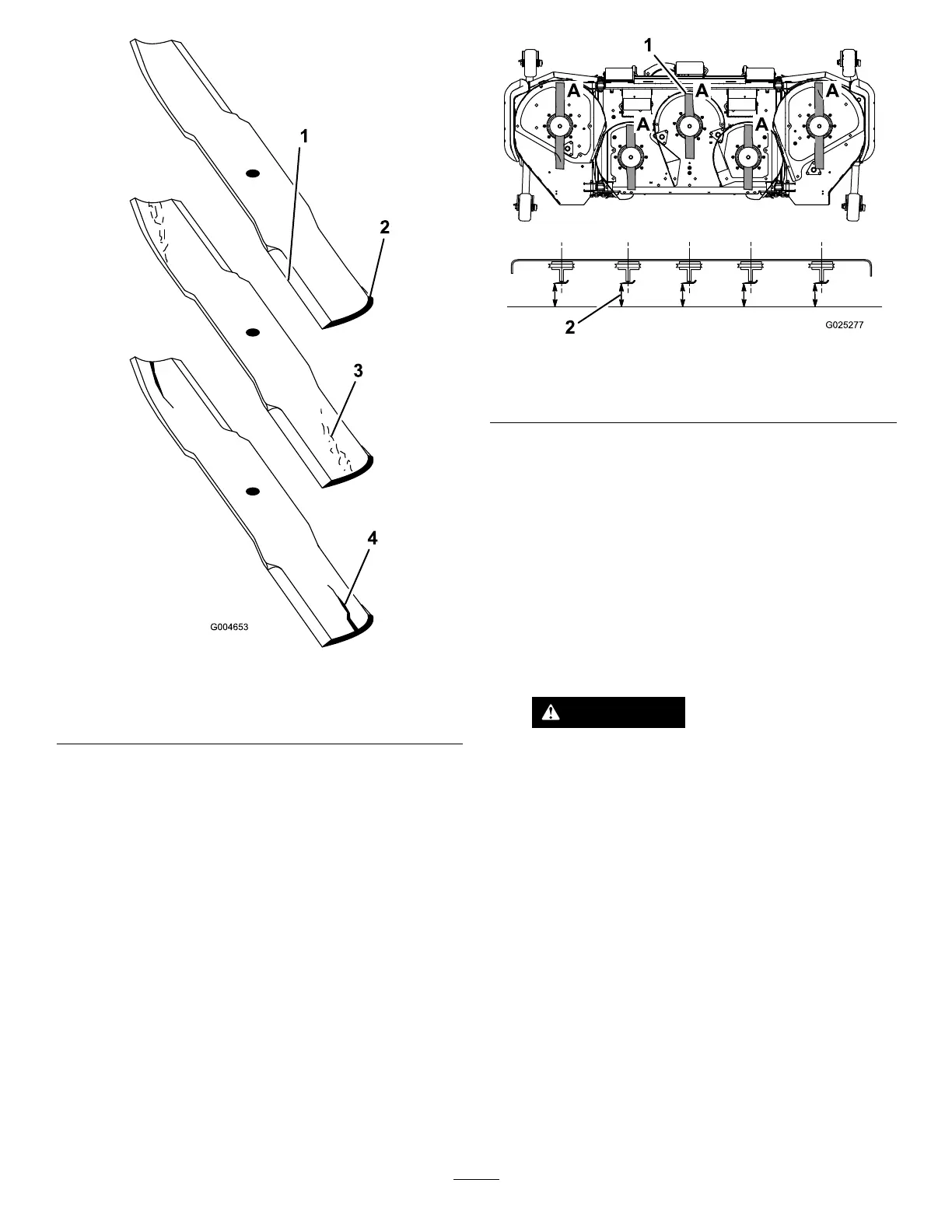

g025277

Figure25

1.PositionA

2.Measureherefromblade

tohardsurface

4.Measurefromalevelsurfacetothecutting

edge,positionA,oftheblades(Figure25).Note

thisdimension.

5.Rotatetheoppositeendsofthebladesforward.

6.Measurefromalevelsurfacetothecuttingedge

ofthebladesatthesamepositionasinstep3

above.Thedifferencebetweenthedimensions

obtainedinsteps3and4mustnotexceed

3mm(1/8inch).Ifthisdimensionexceeds

3mm(1/8inch),thebladeisbentandmustbe

replaced;refertoRemovingtheBlades(page

20)andInstallingtheBlades(page21).

WARNING

Abladethatisbentordamagedcould

breakapartandcouldseriouslyinjureor

killyouorbystanders.

•Alwaysreplacebentordamaged

bladewithanewblade.

•Neverleorcreatesharpnotchesin

theedgesorsurfacesofblade.

RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalanceorisbent.Toensureoptimum

performanceandcontinuedsafetyconformanceof

themachine,usegenuineT ororeplacementblades.

Replacementbladesmadebyothermanufacturers

mayresultinnon-conformancewithsafetystandards.

20

Loading...

Loading...