DriveSystem

Maintenance

CheckingtheTireAir

Pressure

ServiceInterval:Beforeeachuseordaily

Important:Maintaincorrecttirepressureinall

tirestoensurecorrectcontactwiththeturf.

Recommendedtirepressureis1bar(14.5psi)for

generalallarounduse.Adjustthetireairpressures

accordingtothefollowingtabledependingon

operatingconditions.

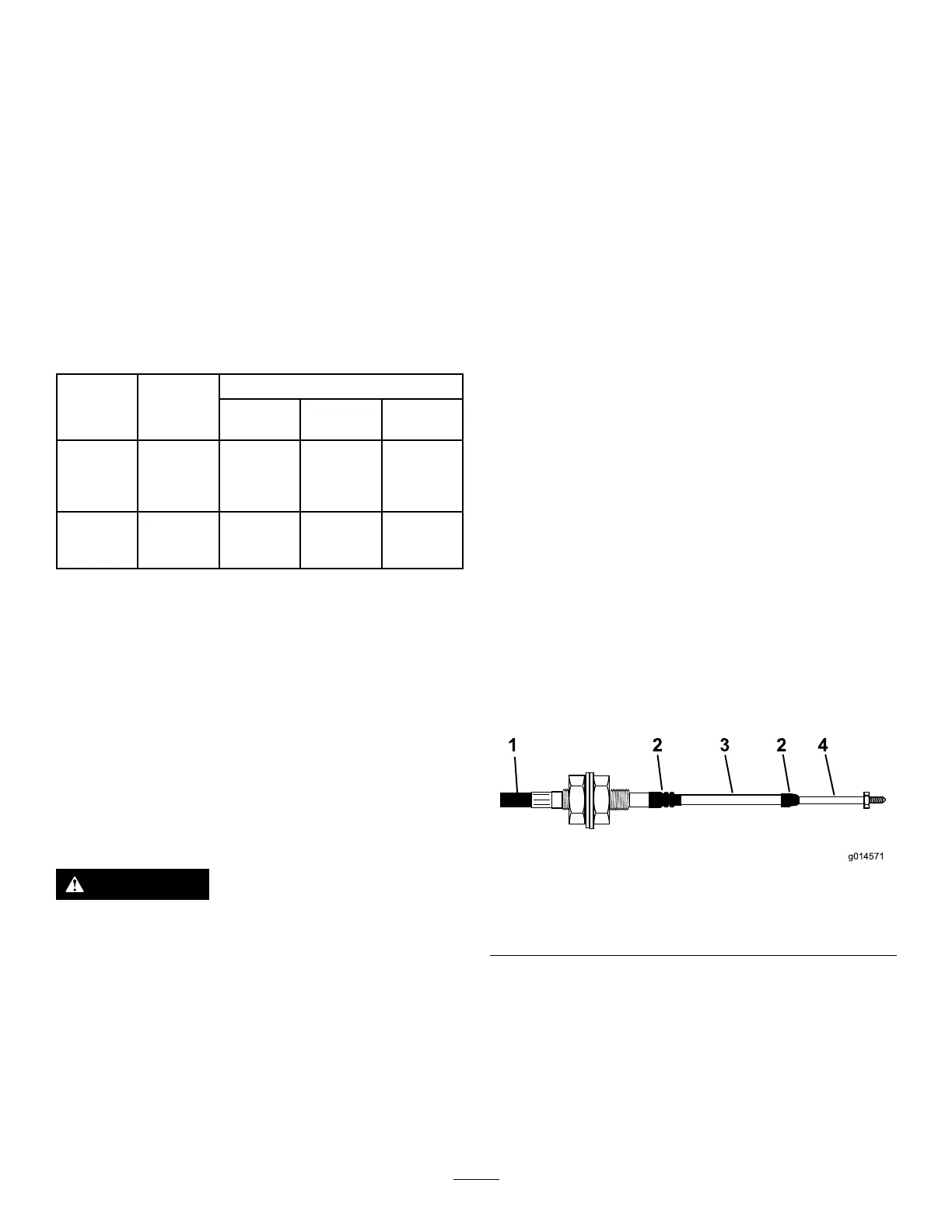

RecommendedTirePressures TiresTireType

Turf

Conditions

Road

Conditions

Maximum

Pressure

FrontAxle26x

12.0-12

BKTturf

pattern

0.7bar(10

psi)

1.4bar(20

psi)

1.4bar(20

psi)

RearAxle20x10.0-

8BKTturf

pattern

0.7bar(10

psi)

1.4bar(20

psi)

1.5bar(22

psi)

CheckingtheTorqueofthe

WheelNuts

ServiceInterval:Afterthersthour

Aftertherst10hours

Every250hours

Frontwheelnutstorquespecication:200N∙m(148

ft-lb)

Rearwheelnutstorquespecication:100N∙m(74

ft-lb)

WARNING

Failuretomaintainpropertorqueofthewheel

nutscouldresultinpersonalinjury.

Maintainthepropertorqueonthewheelnuts.

Inspectingthe

TransmissionControl

CableandOperating

Mechanism

ServiceInterval:Every250hours

Checktheconditionandsecurityofthecableand

operatingmechanismatthespeed-controlpedalsand

transmissionpumpends.

•Removebuildupofdirt,grit,andotherdebris.

•Ensurethattheballjointsaresecurelyanchored

andcheckthatthemountingbracketsandcable

anchorsaretightandfreefromcracks.

•Inspectendttingsforwear,corrosion,broken

springs,andreplaceifnecessary.

•Ensurethattherubbersealsarecorrectlylocated

andareingoodcondition.

•Ensurethatthearticulatingsleevessupporting

theinnercableareingoodconditionandrmly

attachedtotheoutercableassemblyatthe

crimpedconnections.Ifthereareanysigns

ofcrackingordetachmentinstallanewcable

immediately.

•Checkthatsleeves,rods,andinnercablearefree

frombends,kinks,orotherdamage.Iftheyare

not,installanewcableimmediately.

•Withtheengineshutoff,operatethepedal

controlsthroughtheentirerangeandensurethat

themechanismmovessmoothlyandfreelytothe

neutralpositionwithoutstickingorhangingup.

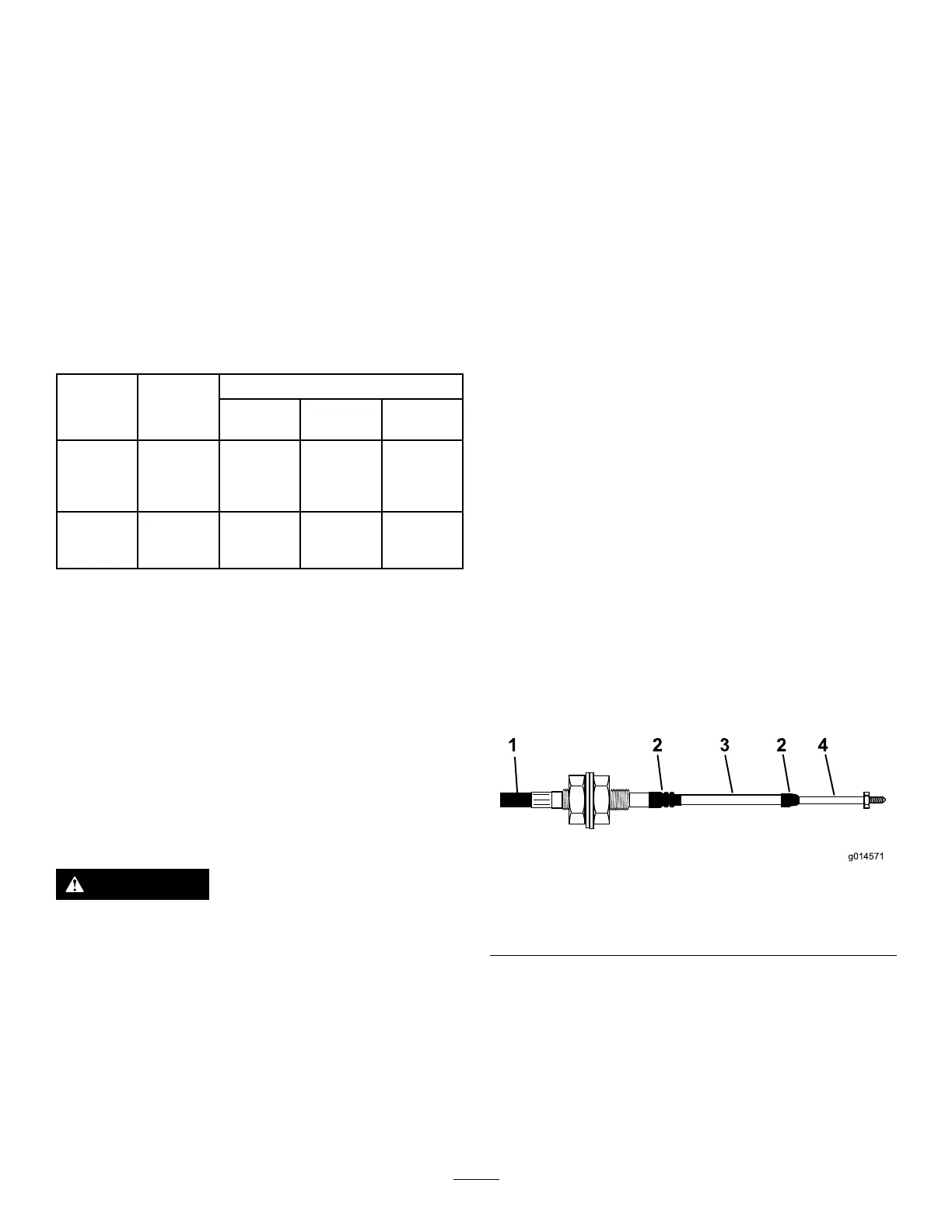

g014571

Figure62

1.Outercover3.Sleeve

2.Rubberseal4.Rodend

50

Loading...

Loading...