CheckingtheCoolantLevel

ServiceInterval:Beforeeachuseordaily

Thecoolingsystemislledwitha50/50solution

ofwaterandpermanentethyleneglycolantifreeze.

Checkthelevelofcoolantintheexpansiontankatthe

beginningofeachdaybeforestartingtheengine.

CAUTION

Iftheenginehasbeenrunning,the

pressurized,hotcoolantcanescapeand

causeburns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

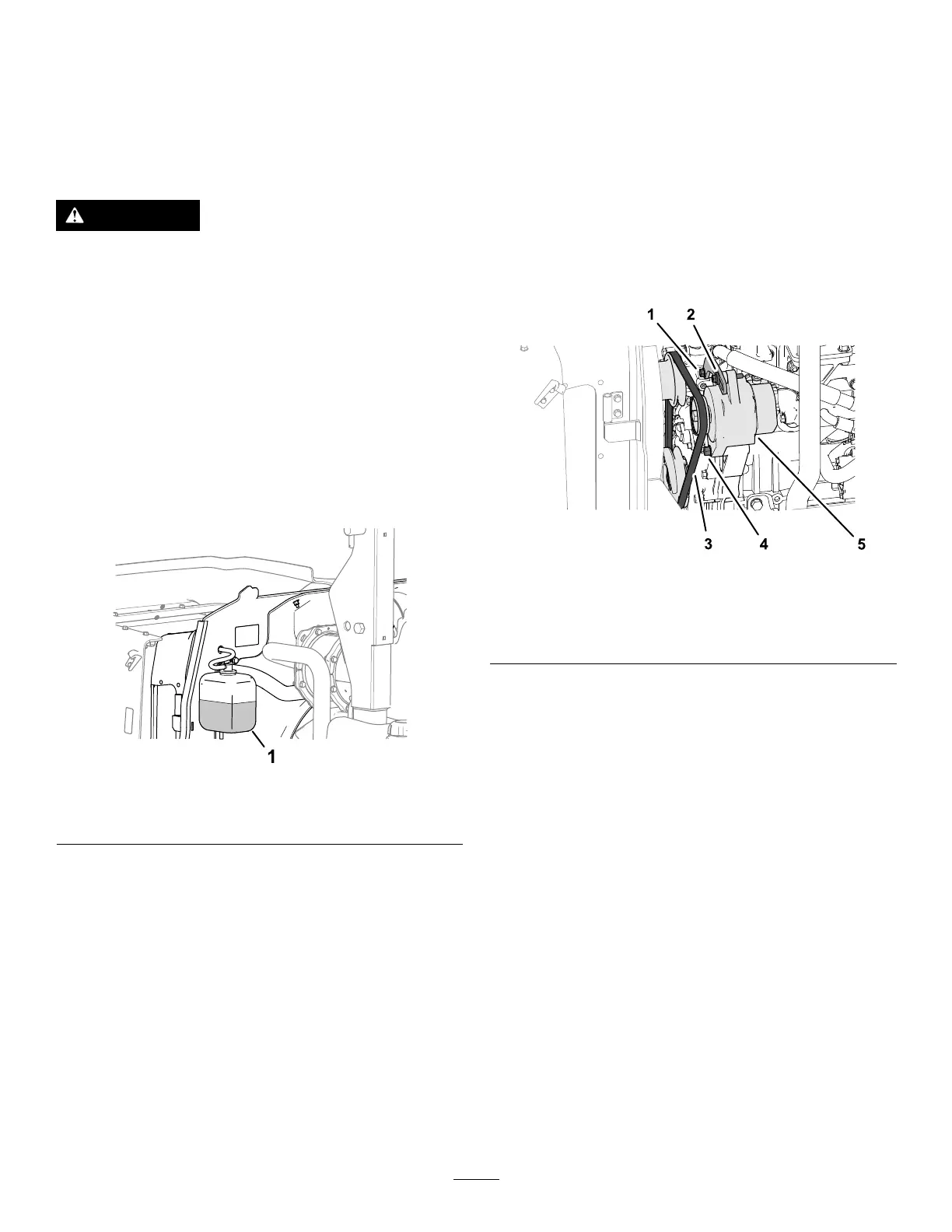

1.Checkthelevelofcoolantintheexpansiontank

(Figure68).

Thecoolantlevelshouldbebetweenthemarks

onthesideofthetank.

g330219

Figure68

1.Expansiontank

2.Ifthecoolantlevelislow,removethe

expansion-tankcapandreplenishthesystem.

Donotoverll.

3.Installtheexpansion-tankcap.

BeltMaintenance

ServicingtheAlternator

Belt

ServiceInterval:Aftertherst50hours

Every250hours

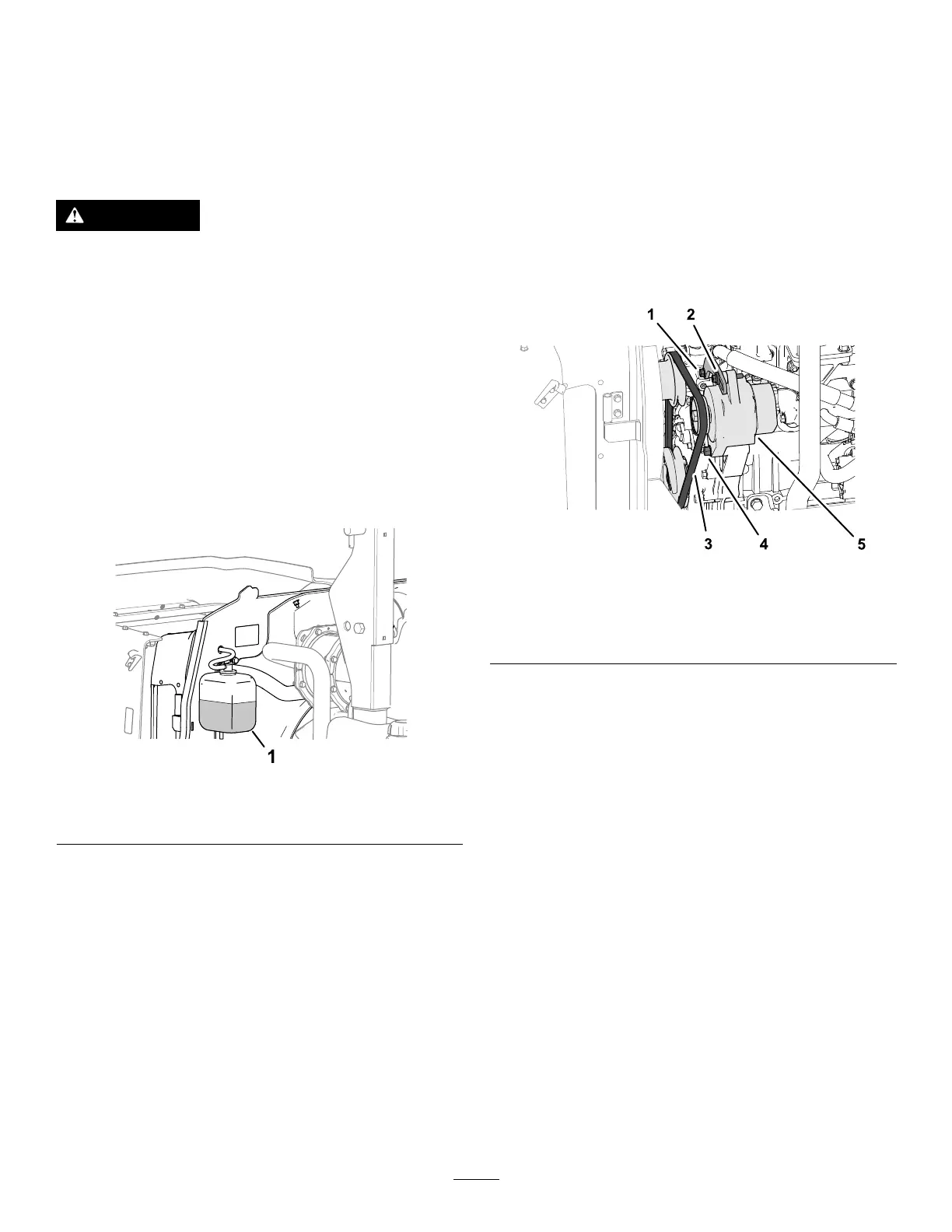

1.Apply10kgf(22lb)offorceagainstthealternator

belt(Figure69),midwaybetweenthepulleys.

Note:Thebeltshoulddeect10mm(3/8inch).

g295237

Figure69

1.Tensionbracketbolt4.Alternatorpivotbolt

2.Alternatortensionbolt5.Alternator

3.Belt

2.Ifthebelttensionisincorrect,performthe

following:

•Ifbeltdeectionislessthan10mm(3/8

inch),loosenthealternatorpivotboltand

tensionbolt(Figure69),andreducethebelt

tension.

•Ifbeltdeectionisgreaterthan10mm(3/8

inch),loosenthealternatorpivotboltand

tensionbolt(Figure69),andincreasethe

belttension.

Note:Ifneeded,loosenthetensionbracket

bolt(Figure69).

3.Tightenthebolts(Figure69).

4.Checkthedeectionofthebeltagaintoensure

correctbelttension.

53

Loading...

Loading...